In this week’s edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments and partnerships across the additive manufacturing sector.

We also explore how Acciona produced the Middle East’s first 3D printed bus stop, what Tech Soft 3D is doing to drive innovation in 3D engineering design software, and why a 3D printed concrete anchor is receiving funding from the Scottish government.

Read on for the latest news from AMT, Protolabs, BigRep, DyeMansion, TE Connectivity, AM-FLOW, Formnext and more.

New partnerships in the 3D printing industry

UK-headquartered Additive Manufacturing Technologies (AMT) has announced Impac Systems Engineering as its first value added seller in the South of the US, encompassing the states of Arizona, Texas, Arkansas, Louisiana and New Mexico. Impac will be an authorized reseller of AMT’s post-processing system, PostPro3D, adding to Impac’s extensive portfolio of 3D printing technologies which already includes Materialise Magics software and HP’s 540/580 and 4200/5200 MJF series.

Elsewhere, in Amsterdam, leading 3D printing services provider Oceanz has announced a partnership with AM-FLOW to develop a series of fully automated AM production lines. The project aims to support the industrialization of AM by automating a number of post-processing steps that are currently done manually and are comparatively time-consuming.

Stefan Rink, CEO of AM-FLOW, stated: “Now is the time that AM becomes a serious alternative for traditional mass production methods. To achieve this, we have to create a fully digital workflow and minimize manual processes. With our AM-FLOW technology, we are able to offer this end-to-end digital industrialization.”

Further South, Australian metal AM specialist Titomic has announced a partnership contract with Ascent Aerospace to bring Titomic’s Kinetic Fusion (TKF) technology to Ascent’s extensive aerospace customer base. The partnership comprises two separate phases. The first is the validation phase, whereby Titomic will produce a customer approved Invar36 tool using its TKF9000 metal AM system. This will act as a production feasibility trial before wide-scale adoption takes place. The second phase is the adoption phase, whereby a joint sales strategy for the supply of aerospace tooling will be established between the two companies. As the global demand for aerospace tooling grows, this will help reduce the long lead-times currently found in the industry.

Titomic has also appointed BTech Innovation as its sales and distribution partner in Turkey. As Titomic’s authorized distributor of systems and metal powders, BTech will offer TKF1000 systems, TKF9000 systems, TKF production line systems, consultation, OEM production, metal powder consumables, and design and prototyping services.

TWI and Leitat, two international research and technology organisations, have announced a partnership to help European SMEs on their path to digitization, specifically implementing 3D printing into their process chains. The aim of the collaboration is to develop projects that will address industrial needs in AM, through research and development, testing and experimenting, and providing educational training in associated technologies. The duo hopes to see an increased AM technology adoption rate in the future.

UK-based Protolabs has announced the decision to add Carbon Digital Light Synthesis (DLS) to its rapidly expanding portfolio of six different AM technologies. The prototyping company’s customer base will now benefit from DLS’s ability to produce intricate designs and durable end-use components that other manufacturing methods currently struggle with. Customers will be offered materials comparable to ABS and polycarbonate, which are known for their consistent industrial-grade mechanical properties.

“We’re very excited about the manufacturing options the Carbon technology offers to our customers,” said Vicki Holt, President and CEO at Protolabs. “It provides a cost-effective production solution for geometric complexities that cannot be molded or otherwise fabricated. We are committed to maintaining our market leadership in being a single source supplier for on-demand services across a multitude of manufacturing methods, and Carbon will help us do that.”

Finally, Solidpro, a HP Gold Partner, has announced that it will be investing in DyeMansion, the world leader in AM finishing systems. The addition of DyeMansion’s post-processing capabilities to Solidpro’s portfolio of services will enable Solidpro customers to have access to the complete AM value chain. Solidpro intends to be more than just a joint sales partner in this instance, as the company will also be offering additional consulting and benchmark production services.

Steffen Hägele, Team Leader, 3D Printing at Solidpro, stated: “We are pleased to have found a strong partner in DyeMansion, who understands the market requirements in the field of post-processing and provides the appropriate solutions and continuously develops them further. The DyeMansion products harmonize perfectly with the HP Multi Jet Fusion technology and support our customers on their path to automated, professional additive manufacturing”.

BigRep marks the delivery of its 500th large-format 3D printer

BigRep, famous for its large-format industrial 3D printers, celebrates the delivery of its 500th industrial system since its inception in 2014. The milestone is the latest news in a string of announcements made by the Berlin-based company, including the opening of 3D PARTLAB, a new 3D printing-on-demand service in Boston. BigRep has also recently launched a new 3D printer, the STUDIO G2, along with four new engineering-grade filaments to boot: PA6/66, PET-CF, PLX and BVOH.

The 500th printer, a BigRep ONE, was delivered to e-mobility technology company JAMADE GERMANY, who recently released an underwater scooter by the name of AMAZEA. An impressive 75% of the AMAZEA’s components are 3D printed.

“We are very excited about this delivery because it represents a new dimension of industrial AM in end-consumer products, both for us as a company and the industry. The new BigRep ONE will enable us to launch the serial production of AMAZEA as planned, completing our existing fleet of four BigRep ONE printers,” says JAMADE Managing Partner and Technical Director, Detlef Klages. “We greatly value the printers’ cost efficiency, accuracy and quality when compared to the extremely high investment for traditional tools.”

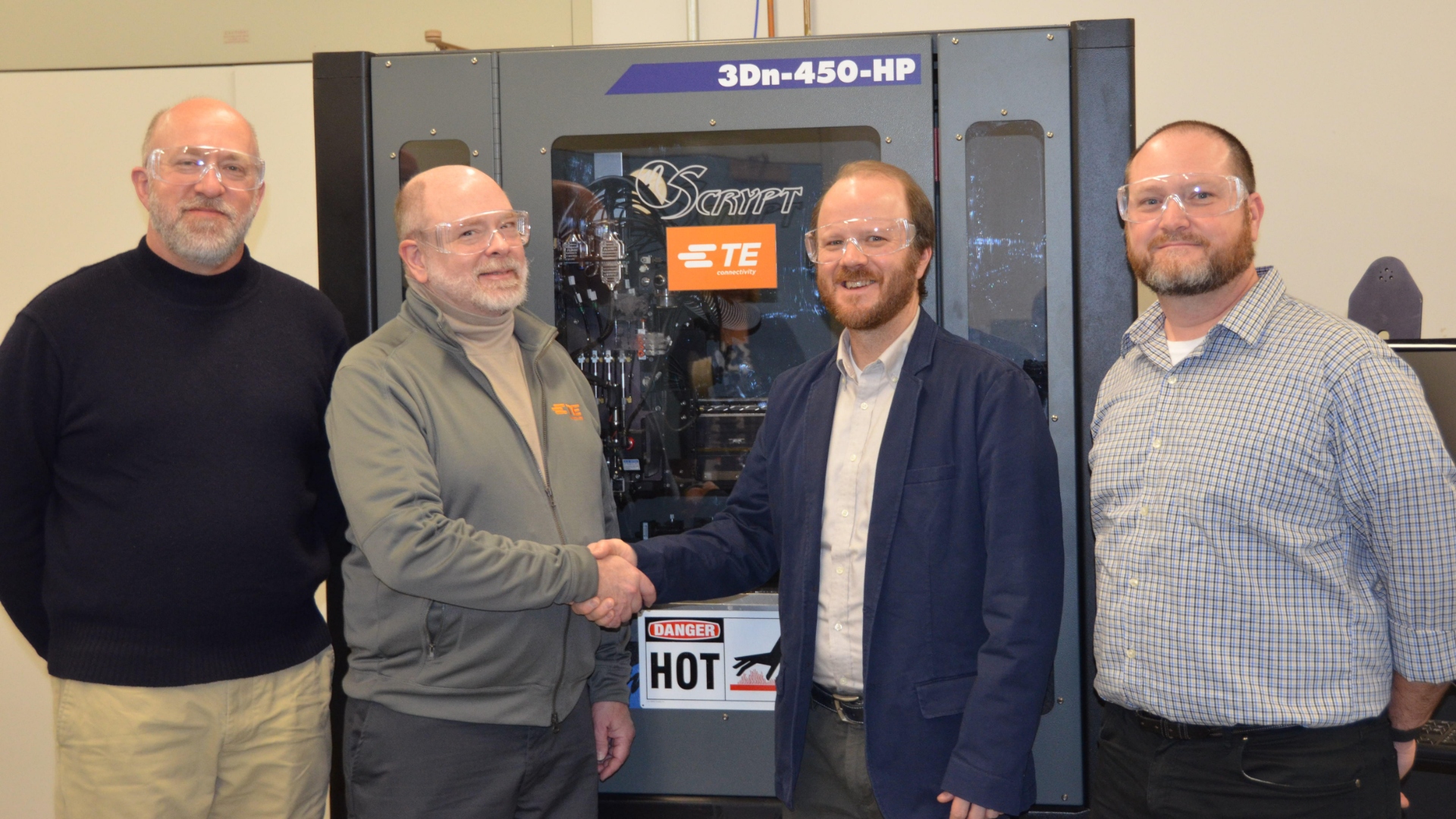

TE Connectivity donates $350,000 3D printer to Penn State University

TE Connectivity’s Middletown, Pennsylvania team has donated a high-capacity, multifunctional nScrypt 3Dn-450-HP 3D printer to the Penn State College of Engineering. The $350,000 donation is intended to support students and researchers in their studies of new AM materials and processes. The college’s engineering faculty will also be using the specialized printer to explore 3D printing on high-power devices.

“This nScrypt printer will facilitate Penn State’s work in multi-material additive manufacturing with a particular focus on integration of metals, ceramics and polymers,” said Mike Hickner, a professor in Penn State’s Materials Science and Engineering Department. “We are interested in furthering additive manufacturing materials science in electronics, biomedical and defense applications.”

Acciona produces the Middle East’s first 3D printed bus stop

Spanish infrastructure and renewable energy company Acciona has unveiled a 3D printed bus stop in the UAE, making it the first of its kind in the Middle East. The three-ton, 4.5 x 2 x 2.3m structure was printed in three pieces over a ten hour period on Acciona’s large-format powder bed concrete printer. It was commissioned by the Ajman Transport Authority and has been installed in the northern emirate.

Tech Soft 3D launches Innovation Lab to give developers early access to software

Tech Soft 3D’s software development toolkits (SDKs) are the building blocks behind many well known 3D engineering software applications, such as SolidWorks and GrabCAD. The Oregon-headquartered company has recently launched a new website, Innovation Lab, to give engineers and developers early access to a number of projects created using its SDKs, among other things. Tech Soft 3D believes that opening up its work and sharing it with the community on the website will drive innovation.

Developers using Innovation Lab will have access to videos and demos of new tools, sample code, and pre-releases of the company’s new HOOPS toolkits and components. Projects that can currently be found on the website include a solid modeling engine running in the cloud, tools for 3D printing, a preview of massive model streaming, and an Android AR demo.

3D printed concrete anchor secures funding from the Scottish Government

Eight technologies have been chosen to receive Scottish Government funding as part of the Floating Wind Technology Acceleration Competition run by the Carbon Trust’s Floating Wind Joint Industry Project. One of the technologies to receive a share of £1M is a mooring system created by RCAM Technologies and the Floating Wind Technology Company, which features a 3D printed concrete anchor. The anchor is sunk and uses suction to embed itself in the seabed. The seven other technologies comprise monitoring and inspection systems, heavy lift maintenance systems, and tow to port maintenance systems.

Events affected by the Coronavirus pandemic

Germany’s oldest AM congress fair, Rapid. Tech 3D, has been postponed to 4 – 6 May 2021 in light of the recent global Coronavirus pandemic. The fair was originally set to take place from 5 – 7 May 2020.

“We did not make this decision easy for ourselves and discussed it in detail with the members of our expert advisory board and partners from the industry in advance. For us, the safety and health of all exhibitors, visitors, partners and employees has top priority. The moving of Rapid.Tech 3D is difficult for us, but it is the most responsible consequence of the current situation,” said Michael Kynast, CEO of Messe Erfurt GmbH and Prof. Dr. Gerd Witt, Chairman of the Rapid.Tech 3D advisory board.

Although the event will not be going forward in May, there have been talks of a 1.5 day “Rapid. Tech 3D Congress 2020” with leading speakers in early September 2020 for the fair to remain relevant in this year’s event market.

Drupa, held every four years in Germany, is the largest printing equipment exhibition in the world. It is a chance for printing press manufacturers like HP to showcase their latest and greatest developments. Before 2020’s event was cancelled, HP announced a portfolio of presses named Indigo, which it intended to display at the event. More than 100 parts in HP’s Indigo drupa portfolio were fabricated using the company’s proprietary MJF technology, including components in the Indigo 100K Digital Press, the Indigo V12 Digital Press, and the Indigo 15K Digital Press.

Elsewhere, in Rome, the Raffaello exhibition, which was to mark the 500 year anniversary of the Renaissance painter’s death, has been cancelled. The exhibition, set to take place at the Scuderie del Quirinale in the Italian capital, would have featured a partially 3D printed life-size replica of Raffaello’s tomb from the Pantheon. The replica’s creator, Factum Arte, has instead digitally revealed the recreation of the tomb as the exhibition is expected to remain closed for the foreseeable future.

Tokyo’s second Formnext Forum opens up exhibitor applications amid pandemic

Following its successful debut in 2019, Formnext Tokyo is now accepting exhibitor applications for its second event set to take place at the Tokyo Metropolitan Industrial Trade Center, Hamamatsucho Hall from 24 – 25 September 2020. Attendees can expect seminars and showcases focusing on additive manufacturing, as well as an informative business platform with networking opportunities.

“Although the novel coronavirus outbreak has caused widespread industry disruption, it has nonetheless opened up additive manufacturing opportunities, with businesses exploring 3D printing as a temporary manufacturing measure to cope with supply chain disruption,” explained Yasushi Kajiwara, Managing Director of Messe Frankfurt Japan. “The upcoming forum will conduct a deep-dive into AM topics across a wide range of industry segments, while also providing networking opportunities to help industry players get back to business as soon as possible. Between now and September, we are confident that the event industry will stabilise and we will liaise with public health authorities to ensure that all of the appropriate safety precautions are implemented at the upcoming forum.”

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sliced logo on a photo of a 3D printed replica of Raffaello’s tomb. Photo via Factum Arte.