In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new materials, partnerships, the acquisition of new facilities, and the launch of the first 100% bio-based 3D-printed house.

Read on for the most recent updates from 6K Additive, Axial3D, Lithoz, Wematter, Meltio, and more.

New hires, business expansions, and recent deals from AML3D, Quickparts, Nexa3D, and more

Diving into the business deals and expansions, Australian metal 3D printing specialist AML3D has placed a purchase agreement with oil and gas company Chevron Australia for the production of two subsea pipeline fittings on typical business terms valued at AU$215,000. These will be manufactured using the company’s WAM technology, which is a type of wire-based Directed Energy Deposition (DED), also recognized as Wire Arc Additive Manufacturing (WAAM).

“This Chevron subsea pipeline fittings order demonstrates continuing delivery against AML3D’s growth strategy, which includes building out the contract and embedded, point of need manufacturing technology solutions in the global oil & gas markets,” said Ryan Millar, CEO, of AML3D.

Furthermore, prototyping company Quickparts is growing its European presence and production team by becoming EN9100 certified. This certification is intended to give the end user more assurance and trust by directly assisting product conformance and safety-critical applications.

The facility contains six metal Additive Manufacturing machinery, along with a vacuum chamber outfitted with DMP 350 machines and a variety of specialized materials, including stainless steel 316L, maraging steel 18Ni300, Inconel 625, and Inconel 718, in addition to other materials (e.g., Ti6Al4V and AlSi10Mg) obtained via outsourcing. The facility assists customers with prototyping, pre-production, and full-series production in a variety of industries including motorsports, automotive, aerospace, and motorsports.

In other news, UK-based rapidly growing additive manufacturing workflow software provider AMFG Corp. has raised $8.5 million in funding led by Intel Capital to further propel it into what the company describes as the “new era of industrial transformation”. Jennifer Ard, an Intel Capital investor, has joined AMFG’s board of directors as part of the latest fundraising round. AMFG will employ this new funding to continue assisting enterprises in scaling their additive manufacturing processes, cementing AMFG’s stance at the frontline of the independent manufacturing revolution.

“AMFG was the solution that best fit our requirements to manage all our streams for Additive Manufacturing,” said Arnaud Cosson, Digital Workflow Engineer at Decathlon, a multinational sports retailer brand with over 2000 stores worldwide. “Connectivity and openness of the platform let us imagine compelling integrations with our ecosystem.”

Moreover, high-speed resin 3D printer manufacturer Nexa3D declared the commercial availability of its QLS 820 laser sintering platform additive production system. The QLS 820, which was initially announced in September 2022, is intended for high-volume manufacturing of thermoplastic components. It has the highest throughput in its class, with a print rate of up to 8 liters per hour and a packing density of up to 20%. The QLS 820 showcases a novel class of powder bed technology that integrates ultrafast printing with open materials and a cloud-based software platform to produce numerous orders of magnitude with higher production quantities than other powder-bed solutions currently available.

“My hat is off to our entire team of determined innovators, passionate engineers, and experienced marketers for bringing to market an industry-leading thermoplastic production platform that fully delivers on our ultrafast brand promise,” said Avi Reichental, co-founder, and CEO, of Nexa3D.

Emerging partnership news from Xact Metal, Axial3D, Wematter, Rhino3D, and more

Now proceeding toward the partnerships in the AM sector, the first partnership we will be talking about is that of Xact Metal and Varinex. Xact Metal and Varinex announced a sales and service partnership with the goal of increasing the availability of affordable metal 3D printing for small-to-medium-sized businesses and decentralizing additive manufacturing.

“At Xact Metal, we’re establishing a new level of price and performance in metal 3d printing by taking the essential specs of metal additive manufacturing and combining them with breakthrough technology,” said Juan Mario Gomez, CEO of Xact Metal. “We are pleased to partner with Varinex in Hungary, one of the top industrial economies in eastern Europe. Varinex’s strong product line of industrial 3D printers and their application expertise across many industries will enable us to quickly help customers realize the benefits of 3D metal printing.”

The next partnership is between med-tech startup Axial3D and Stratasys. Axial3D announced the conclusion of a $15 million investment round headed by a $10 million investment from Stratasys Ltd. The two firms will also offer a joint offering to create patient-specific 3D printing solutions more available to hospitals and medical device makers, allowing it to evolve into a conventional healthcare solution.

“Many of the world’s leading hospitals are already benefiting from our MediJet and Digital Anatomy 3D printers for medical models,” said Dr. Yoav Zeif, CEO of Stratasys. “We believe that by working together with Axial3D, we can remove the barriers to entry for the remaining majority of hospitals in many countries around the world, dramatically growing the use of 3D printing in pre-surgical planning so it is truly a standard part of patient care.”

Furthermore, US-based precision filtration company Mott Corporation and Conflux Technology, an Australian specialist in Additive Manufacturing heat exchanger specialist have announced a collaboration which will deliver Conflux’s AM thermal solutions to North American markets.

Conflux’s additively manufactured heat exchangers are claimed to enhance the thermal management of vital parts in a variety of industries such as aerospace, automotive, motorsports, microelectronics, industrial, and energy.

Elsewhere, Wematter, a Swedish 3D printer manufacturer, has signed a distribution deal with a Dutch reseller 3D Supplier to develop a Benelux sales and service system for the Gravity SLS 3D printer. Malcolm Riesewijk, founder, and CEO at 3D Supplier said, “What makes the Wematter Gravity 3D printer unique is that it has a large build volume for an affordable price as well as their material range with the unique closed system where the powder is in cylinders so you can work without a mess and keep a clean working area. Wematter always tries to find a solution to make a Gravity 3D printer available for your company.”

The next partnership is in the construction sector. 3D construction printing technology supplier COBOD has established a joint venture (JV) with Modula, a PT Bakrie & Brothers Tbk (BNBR) subsidiary. The JV collaborators will form a committed Indonesian joint venture firm to expand the 3D construction printing market in Indonesia. In collaboration with COBOD, the company is now preparing to implement the most recent 3D construction printing (3DCP) technology and to provide the Indonesian market with a new and enhanced solution for housing construction.

Followed by nScrypt who is now an authorized reseller of the Rhino 3D CAD software. The software will be used in conjunction with its nStudio software engine for its Factory in a Tool 3D Manufacturing systems. Non-Uniform Rational B-Splines (NURBS) surfaces, solids, and curves, subdivision geometry (SubD), polygon meshes, and point clouds, can be created, edited, analyzed, documented, rendered, animated, and translated using Rhino freeform modeling tools. According to the Rhino team, there are no boundaries to complexity, degree, or size other than those of the hardware, and Rhino can prototype any structure imaginable.

Industrial 3D printing solutions provider Meltio, announced that EXBuild will serve a significant role in the distribution and assistance of Meltio wire laser metal 3D printing solutions in the Mountain West and Midwestern marketplaces as an official sales partner. EXBuild provides services, sales, training, software, and hardware, for industrial resin, composite, and metal 3D printing. Meltio’s official sales partner, EXBuild, will collaborate with tooling machine companies, academia, technology centers, robotic integrators, and industry to develop a suitable ecosystem for the company’s technology.

In other news, On behalf of President Neal Orringer, ASTRO America issued the following statement regarding Lockheed Martin and Sintavia‘s partnership to broaden the exploration of metal additive manufacturing (AM) possibilities as an alternative to castings and forgings. The partnership illustrates ASTRO’s dedication to the AM Forward initiative, which was launched earlier this month with President Biden. President Biden launched the campaign in May. Honeywell, Boeing, Lockheed Martin, GE, Siemens Energy, Northrop Grumman, and Raytheon Technologies, are among the Compact partners.

Sintavia serves as an AM supplier to Lockheed Martin, assisting several programs in metal additive manufacturing. The partnership approach will look into extra AM technology areas such as laser powder bed fusion, electron beam-directed energy deposition, and friction stir AM, according to the companies.

Introducing new materials from 6K Additive and Lithoz

Additive manufacturing has an abundance of materials. This edition of sliced is going to focus on two novel materials addition in the sector. First, 6K Additive, a division of 6K, announced the availability of ultra-low oxygen titanium 64 with components per million in the 500-700 range.

“The global supply chain crisis has caused volatility in the market for metals like titanium which leads to uncertainty in costs and availability. Our ability to provide low-oxygen titanium at production volumes enables our customer to stretch their powder use well beyond what’s available today, essentially increasing value and lowering costs for their Ti64 parts,” said Frank Roberts, president of 6K Additive.

The UniMelt platform from 6K provides multifaceted environmental advantages unmatched by any other material production platform worldwide. Foresight Management was recently commissioned by 6K Additive to undertake a life cycle assessment of their nickel and titanium powders. The purpose of this study was to evaluate the ecological impact of manufacturing printable metal powders and to particularly compare atomization technology methods to 6K Additive. It was discovered that 6K’s UniMelt process provided at least a 74% energy reduction and a 78% emission reduction over conventional methods for Ti64.

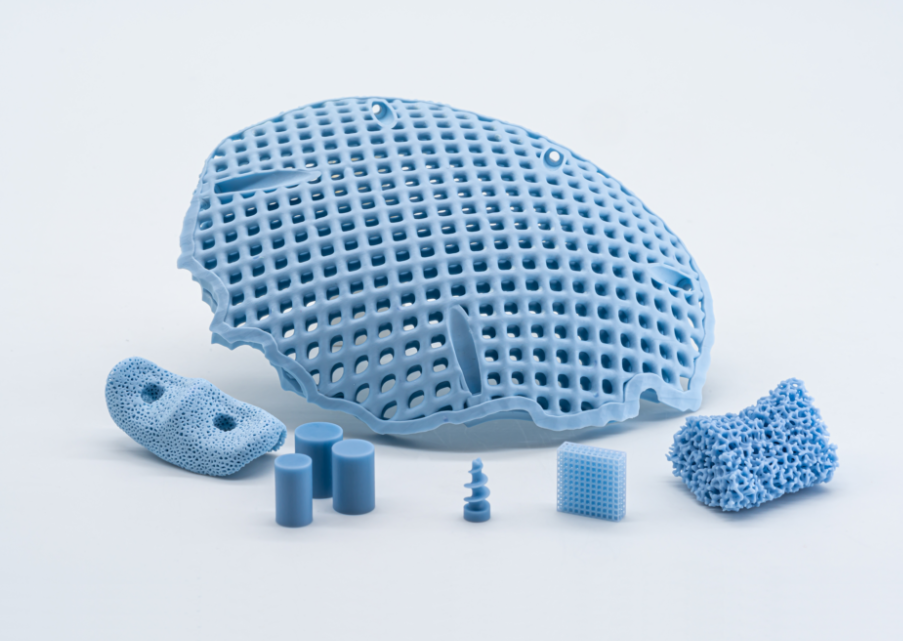

Meanwhile, Lithoz introduced the new LithaBone HA 480. The significantly improved human bone-like ceramic material, which aims to render the material more financially feasible and the utilization of 3D printing for bone replacements more effective, received a warm welcome from expert visitors at its debut at Formnext 2022, where the distinctively blue complex parts on display piqued their interest.

Since 2015, KLS Martin, a pioneering German medical technology company, has been a significant client of 3D printed bone substitute implants. LithaBone HA 480 and the specification of development objectives were overall the direct outcomes of this partnership’s invaluable customer feedback.

”We at KLS have been producing CMF implants for human use on our Lithoz CeraFab printer since 2015, with excellent results in terms of accuracy of fit, tolerability, and healing success. We already have had the chance to work with HA 480 and the results are outstanding: from mechanical properties over higher wall thickness to size and lattice structures, LithaBone HA 480 has convinced us of a considerable improvement compared to its predecessor,” said Adem Aksu Director Development Biomaterials at KLS.

Acquisition of new facilities by Fabrisonic, Incodema3D, and more

Apart from new partnerships, and materials there have been a few acquisitions of new facilities to streamline the manufacturing process of the companies. 3D metal Ultrasonic Additive Manufacturing (UAM) and 3D printing applications manufacturer Fabrisonic, being the first in line has announced a relocation to a larger, “state-of-the-art” facility in Lewis Center, Ohio. Since 2011, EWI has been incubating Fabrisonic at its Columbus facility on the premises of Ohio State University. The company is expanding and now needs extra space to accommodate more people, machines, and increased part manufacturing.

7719 Graphics Way, Suite A, Lewis Center, OH 43035 is the address for the new 30,000-square-foot facility. The company intends to add a SonicLayer 4000 along with a SonicLayer 1600, which will increase the capacity for parts manufacturing, new capability development, and customer development.

On the other hand, Incodema3D, an Incodema spinoff company, has procured an EOS M 300-4 system, which will be used to expand Incodema3D’s industrial 3D printing production capabilities. With the addition of this new device, Incodema3D now has sixteen EOS 3D printers on-site, enabling the company to generate small and medium-sized parts in large quantities, creating it the first platform they consider when addressing production scaling with customers. Incodema3D and EOS have been working together for ten years, beginning with the purchase of their initial EOS M 280, a precursor to the existing EOS M 290 midframe metal 3D printer. Their EOS fleet has expanded since then to encompass nine EOS M 280s, two EOS M 290s, four EOS M 400s, and now the EOS M 300-4.

Elsewhere, high-quality 3D solutions provider Hobs 3D has announced a new alliance with Hybrid Services, a Mimaki printer supplier in the UK and Ireland. The implementation of a Mimaki 3DUJ-2207 – a high-definition 3D printer with full-color modeling capabilities – expands Hobs 3D’s product line. The 3D printed output is suitable for creating precise prototypes along with complex architectural models, complementing Hobs’ existing clientele.

Triastek receives FDA Approval for its 3D printed drug T21

Receiving FDA approval is a huge milestone for any firm. The US Food and Drug Administration (FDA) has approved Triastek‘s IND (Investigational New Drug) application for T21, a 3D printed drug that will be employed to diagnose Crohn’s disease. Since its inception in 2015, they have focused on digital drug development, dosage form design, and smart manufacturing.

Melt extrusion deposition (MED) is the 3D printing technology used here, wherein powdery starting materials are processed to a molten or soft state. Then, layer after layer of material is applied until the 3D printed drug T21 is realized. The novel feature of using additive manufacturing is the aimed delivery of the drug intended for the colon. In this case, the drug can focus on the large intestine section of the gastrointestinal tract, allowing for a lesser drug dose whilst also producing the same effect. Triastek was also able to utilize radioactive imaging agents at a preliminary phase in the drug’s progression. This implies that the location of the release of drugs inside the gastrointestinal tract could be evaluated. Finally, this signifies that future drugs will be capable of targeting specific segments of the gastrointestinal tract with higher success rates and efficiency. The company states that this technology can be employed not only for oral sustained-release tablets but also for additional research into peptide drugs.

3D printed constructions, applications, technology, and more

BioHome3D, the first 3D printed house constructed completely of bio-based materials, was debuted on November 21 by the University of Maine Advanced Structures and Composites Center (ASCC). BioHome3D was created with financing from the US Department of Energy’s Hub and Spoke program, a collaboration between the University of Maine and Oak Ridge National Laboratory. MaineHousing and the Maine Technology Institute were among the collaborators. The 600-square-foot prototype has 3D printed wood fiber and bio-resin walls, roofs, and floors. With 100% wood insulation and customizable R-values, the house is completely recyclable and highly insulated. Because of the accuracy of the printing process, waste materials were nearly eliminated.

Previously, global deep-tech food manufacturer Steakholder Foods Ltd, announced it has issued a provisional US patent application based on a novel formation of tissue layers to produce cooked fish’s distinctive tender flakiness. The product structure is composed of multiple layers with loose bonding between them. The new method, which will be employed in conjunction with the company’s 3D printing technology, is anticipated to allow for the production of a variety of fish, cuts, and seafood.

Moreover, after the completion of a multiyear project, partners on a BMBF initiative have disclosed their representation of a production approach that they presume will allow large corporations along with SMEs (small and medium-sized businesses) to financially manufacture individualized parts in medium batch sizes.

Three years ago, Project IDEA was initiated with the objective of industrializing additive manufacturing for both OEMs and SMEs. Industry partners, two Fraunhofer Institutes (Laser Technology ILT and Production Technology IPT), and RWTH Aachen University collaborated on the project. The collaborators constructed two automated, additive manufacturing lines for metal 3D printing with exceptional performance as part of the project to generate powerful high-end parts like those used in gas turbines.

Furthermore, global 3D printing solutions provider B9Creations has introduced a K-12 education division that offers customized service and technology offerings, building on a long tradition of serving the higher research and educational market with technology in over 60 universities worldwide. B9Creations is now collaborating with Rapid City Area Schools (RCAS) to produce a pathway for STEM potentials for the area’s nearly 14,000 students as part of a fresh education program piloted at various schools in the district. RCAS intends to offer comprehensive STEM education that allows for experimental, inquiry-based experiences, while also creating a fun, hands-on learning environment, that empowers creativity and innovation while simultaneously enhancing and practicing problem-solving skills, and assisting students to develop and prepare for post-graduation plans.

“Our goal is to provide students with the necessary skillsets for future careers. We have several stations set up in the classroom, and at the 3D printing and CAD stations, we have lists of potential careers posted so the kids are able to understand how the skills they’re developing in the classroom can be applied in future careers,” said Greg Gramberg, technology education teacher at RCAS.

Follow this link for all the 3D Printing Trends 2023.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows LithaBone HA 480. Image via Lithoz.