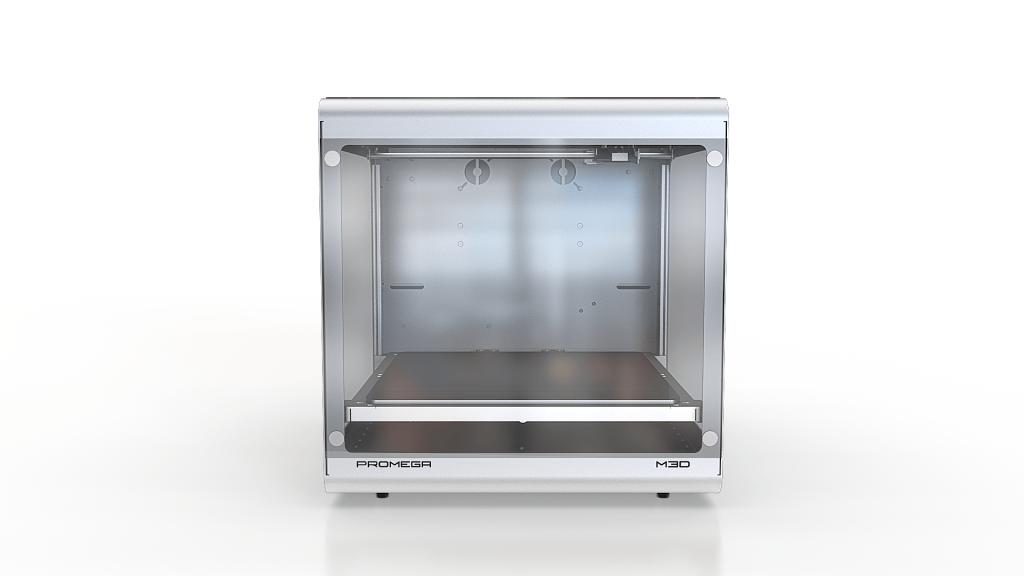

M3D, once a producer exclusively of personal desktop 3D printers, is now branching out into the professional market with the Promega 3D printer.

The Promega, an open source industrial 3D printer, aims to bring something new to the already popular field of FDM printing machines with its affordability, design and reliability. It also marks M3D’s journey from startup to commercial manufacturer.

For Michael Armani, co-founder and CEO of M3D, the most important thing is that users get what they expect to from a professional 3D printer, for better value than alternatives. “What we’ve been able to do is innovate every aspect of the printer to create a large-scale, commercial-grade 3D printer for that same build volume of 2.08 cubic feet, yet at $3,500,” he explains.

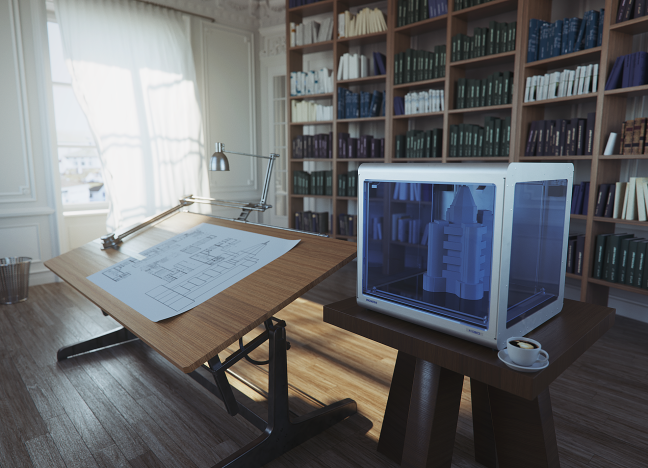

M3D says that along with purchase cost savings of 30% compared to other machines with similar specs, and an estimated 83% lower operating cost, the Promega already looks to be a contender in the industry. Armani adds, “We shouldn’t leave out aesthetics, either. The Promega is a slick-looking printer that’s worthy of showing off in a professional setting; not one that’s put in the back room. In the end, 3D printing experts and professional entities will appreciate its size, its value, its quality and its look.”

It is important to Armani to keep the product affordable, making it relevant both to major industrial manufacturers and also other designers such as “Architects, Engineers and other professionals where impressing visiting clientele can help them win jobs.”

A user-friendly and practical 3D printer

I asked Michael Armani why the professional market was the next step for M3D. He gives a neat little analogy, “If a low cost DIY printer is analogous to a go-cart then a consumer 3D printer is like a compact car and a professional 3D printer is a hot-rod”. The risks, need for repairs or tuning and lack of customizability in low-cost DIY 3D printers far outweigh their advantages.

“The professional 3D printers take everything to the next level by being reliable, safe, and being able to go as fast as possible while needing tuning on a pre-determined schedule. With the Promega we aim to offer all of these things while also providing for an unprecedented price point and by completely unlocking the software, firmware, and electronics.”

The freedom is brought back to the user, “The Promega addresses the issues where replacing parts becomes expensive, modifying the system is impossible, or printers are locked down to using their own materials – whether by chip cartridges or by scaring users through aggressive warranties”.

It also ticks the boxes of printer networking and energy efficiency. “The reality of 3D printing is that a one size fits all setting is about 2-5 times slower than a truly optimized setup. Open source, then, allows companies to further customize and scale their printers to their specific need, for instance extruding softer materials with high flow rates or turning corners at maximum speed.

Moving into the industrial 3D printing market

With the change from consumer-based startup to multi-offering company, changes have been widespread, “our shift to open source is a big difference to how our consumer-line of products operates, and soon enough, our manufacturing will follow-suit and realize some differences, as well.”

But M3D seems ready to deal with the competition with confidence and affordability on their side, “Our first entry into the marketplace will be to establish the Promega as a serious contender within the price range and the build-size 3D printer options with them.”

Armani continues, “Soon enough, the community will start using the Promega, which will prove itself as being a reliable and quality 3D printer worthy of a $3,500 price point. We know being recognized as the ‘go-to’ large-scale 3D printer isn’t an easy accomplishment, but we’re up to the task to earn that title.”

Trading up to the M3D Promega

M3D is so confident of its surely forthcoming status that it is offering a trade-in with any other desktop 3D printer to count towards the value of a Promega.

Of course, it comes down to the best 3D printer for the workflow. “Whether a company uses 3D printing for manufacturing, architectural, engineering or other design purposes, 3D printing will move more and more forward into their workflows as adaptation and familiarity for it increases.”

Even those less familiar 3D printing may turn to it in time. “Users will start to see how it aids in speeding up the iterative process with molds and designs, and therefore turn to 3D printing not just in final project phases, but to help them with initial concepting, then help as they work through versions until ultimately reaching the final project phase.”

Michael Armani explains, “In the end 3D printing will allow companies to work faster, work smarter and in the end, work better.”

The Promega 3D printer is currently priced in the low $1,600’s and can be pre-ordered here.

Subscribe to our free newsletter for more information the current printers on the market. Also like us on Facebook and follow us on Twitter.

Featured image shows M3D co-founders David Jones (L) and Michael Armani (R). Photo via Baltimore Business Journal.