A case study conducted in Portugal has used 3D printing to help reconstruct the eye of 47 year old woman. In taking a digital approach to prosthesis manufacturing, researchers at the University of Porto, and the Institute of Science and Innovation in Mechanical and Industrial Engineering managed to produce a high quality prosthetic eye whilst cutting the time and cost of a typical approach.

The traditional approach

The patient in this study suffered a facial injury about 5 years ago. At the time, the complexity of the defect made surgeons unable to reconstruct the left eye. Alternatives since then have been inexpensive, non-bespoke, prosthesis that cause discomfort when worn, or custom-made, well fitting eyes that are costly to make.

Typically, a custom prosthetic eye requires the help of specialist anaplastologist, and a long waiting list due to demand. In the U.S., the efforts also cost anything from $1,800 – $8,300 dependent on materials, finish and fit.

The digital approach

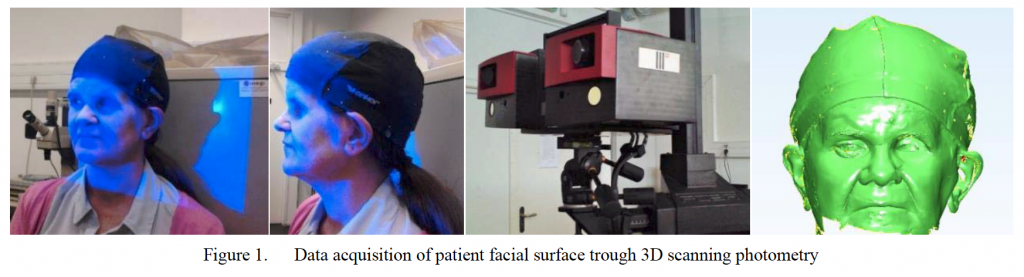

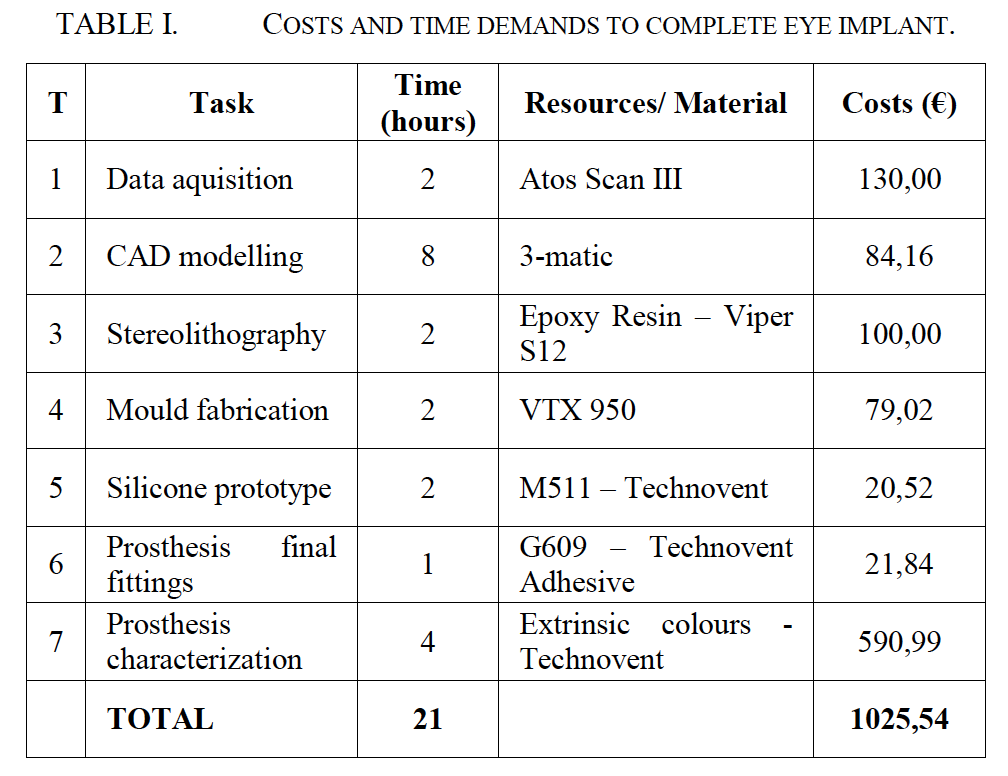

In this study, researchers integrate 3D scanning, CAD modeling, and stereolithography into the process. In place of using CT scans of the patient’s face, the shape is precisely mapped using an ATOS III structured light 3D scanner from GOM. The point-cloud data from this hardware is then much easier to work with in CAD as the file size is not as large as that in a CT image.

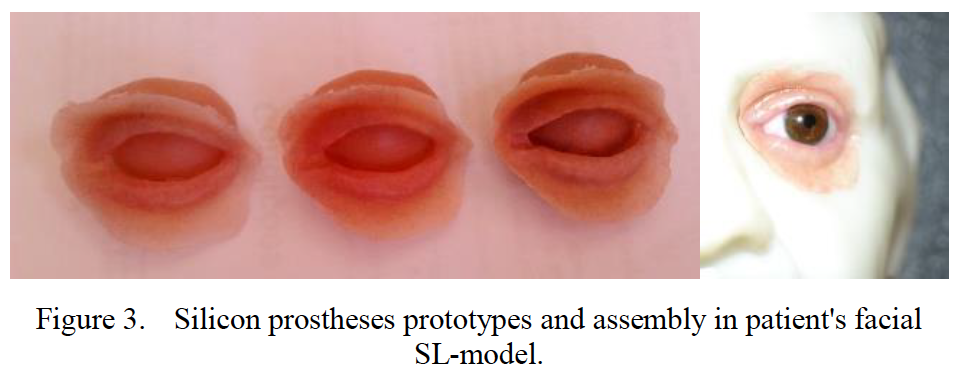

With this model, a designer sculpts the appropriate eyelid and socket shape to house an artificial lens. This shape is then 3D printed in resin on a Viper S12 SLA system, and used as a mold to make silicone prototypes. In trying out the prototypes in the patient’s face, adjustments are made to achieve the perfect fit.

An acrylic lens matching the color of the patient’s right eye is then inserted into the silicone mold, producing a visually accurate prosthetic eye for the equivalent of $1092. Even in the lower end of the U.S. prosthetic market, the method shows a significant saving of over $700.

Improved quality of life and self-esteem

In the final remarks of the study, authors note,

The proposed methodology showed promising outcomes in terms of time and costs, allowing the achievement of prosthesis with a minimal level of discomfort, disclosing excellent aesthetic and functional results […]

In addition, the result “shows a high social impact as it contributes to an accurate and effective restoring of patient’s physiognomy and, at the same time, improve individual selfesteem and quality of life.”

Taking note of such possibilities with 3D printing for reconstructive surgery, UK based additive manufacturing and engineering company Renishaw has developed its own software to aid in making facial implants. 3D printing has also proved to be advantageous to creating more cost-effective arm and leg prosthesis, as in the Enable Community Foundation that is helping amputees in Haiti.

The study in this article was presented at the 5th Portuguese Meeting on Bioengineering in 2017. It is co-authored by Mafalda Couto, Margarida Machado, Ana Reis, Rui Neto and Jorge L. Alves. Full details of the study, including supporting methodology and findings are accessible online here.

To stay up to date with the latest medical research to use 3D printing sign up to the 3D Printing Industry newsletter and follow our active social media channels.

Featured image shows eye photo by Piotr Szczepankiewicz, piotr_szczepankiewicz on Flickr