One of the biggest benefits of 3D printing is de-localized production. That means you can put a bunch of 3D printers anywhere in the world and have a small, environmentally sustainable factory. That, however, is not entirely de-localized production, since the production still happens in one place, just a potentially remote one. Truly delocalized production is what the TOME Hackaday prize project wants to offer, by developing a portable, battery powered, 3D printer.

The Hackaday prize will award a trip to space for the open source project – submitted by early next August – that will have the greatest social impact. It has been a rich resource for impressive 3D printing projects (such as the metal FDM printer we reported on a couple of two weeks ago). The TOME, by 25 year old electro-mechanical engineer Philip Ian Haasnoot, also meets the contest’s social impact requirements.

It is meant to be allow potable 3D printing, especially in emergency situations such as field hospitals or other remote situations where supplies are limited. The possibilities are endless and it makes perfect sense: if we are considering using 3D printers to be able to print tools on-demand for future long term space missions, why not use them when necessary here on Earth as well?

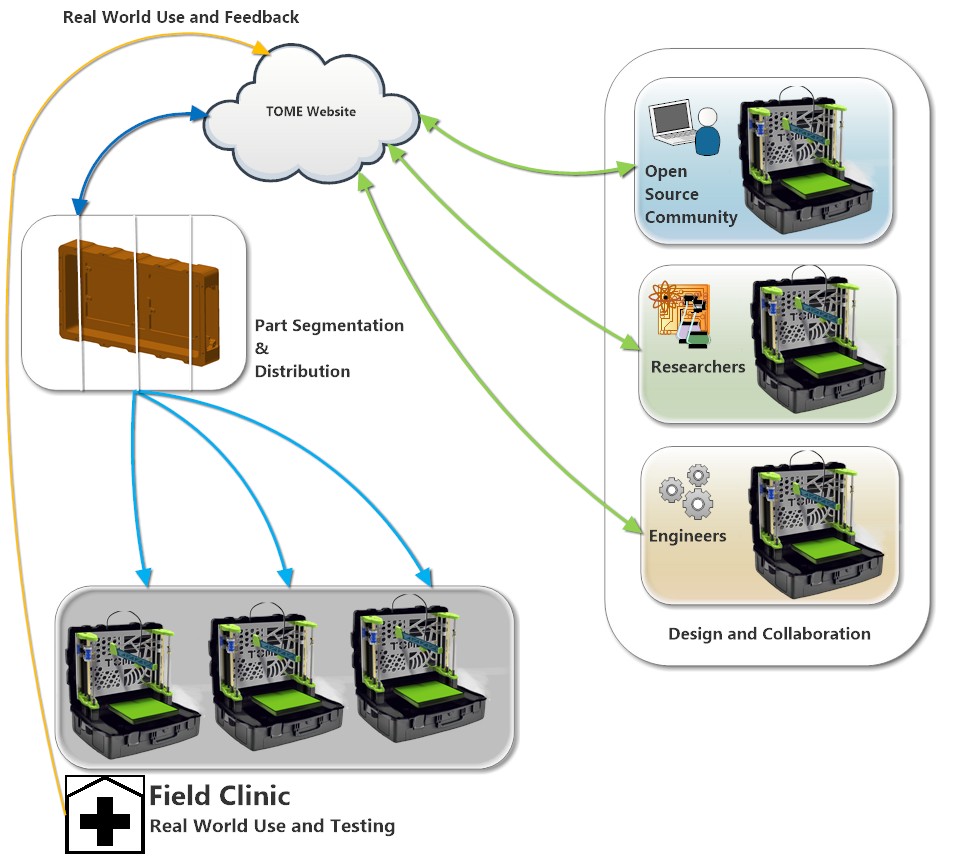

Haasnoot envisions a team of nomadic engineers being able to collaboratively operate in different places to print parts of a system and then converge in one place to assemble it (can I also suggest a partnership with Engineers without Borders?). More TOME 3D printers converging in one place together could be used to produce large and complex parts.

The project is currently shooting for a 5 cubic inches print volume, optimized for PLA, with a heated bed for better adherence. Battery print time (this is an interesting concept that I am sure will be explored further in the near future) will be 4 hours and up to 6 hours with an extended battery pack (the battery chemistry has not yet been decided on). It is intended that the machine will be able to print wirelessly and support networking by allowing a desktop application to separate the file among several printers.

My personal opinion is that the project is extremely complex and will prove very difficult to realise. However, whether Haasnoot and his team succeed on this first try or not, there is not doubt that this is one of the most important directions that personal 3D printing technologies will undertake. Multiple, collaborative, and most of all, truly delocalized production, anywhere, at any time.