When it comes to 3D printing, thoughts often tend towards the endless opportunities to build and create things and shapes that were previously impossible. However, 3D printing is also a perfect technology for fixing the previously unfixable, when producing spare parts either isn’t viable or it’s insanely expensive.

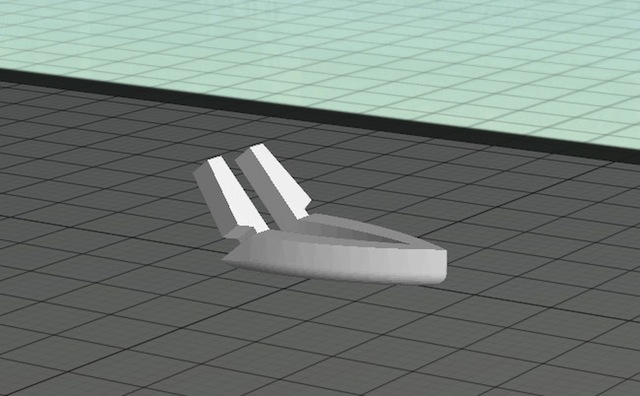

Throwing the lamp away or buying a new lamp seemed like such a waste just because a tiny little piece was missing. After 15 minutes of dimension estimating and CAD action, the 3D design was ready. It’s a simple design of a small piece that needs to bend in order to fit the socket in the lamp.

This is where a MakerBot Replicator 2 came to the rescue, with some nifty design skills. You can see the printed part side by side with the original piece in the photo gallery below. The replacement part took around 25 minutes to produce.

[nggallery id=72]This was very much an experimental design and 3D printing job, so expectations for the piece to fit on a first try weren’t that high. Exceeding all expectations the piece fit perfectly! (I think the red colour adds personality to the IKEA lamp).

Just five years ago, creating a fix like this just would not have been possible. And although it is probably still a while until this becomes standard practice for many it is great to see that it is possible and it is happening now. Sometimes the problem and the solution – enabled by 3D printing – are really simple. Moving forward, 3D printing will also likely become a tool for solving and fixing more complex problems. In this case the whole process took 30-40 minutes from starting to finish. That’s really amazing!

Of course, certain skill levels were needed to do this, but again, in time, as the tools available become more consumer friendly it will allow a wider audience to use them. And, the coolest part of all in this, is the whole sharing aspect and open source mentality — this was a problem experienced by an individual, but now anyone else with that same problem does not have to start from scratch and has an alternative to binning a lamp and buying a new one. Open source websites are fantastic for this. In this case the IKEA lamp fix design is available at Thingiverse.