North American 3D printer manufacturer Stratasys is supporting the development of the “world’s first all-electric commuter plane,” while Belgian 3D printing company Materialise has a key role in the development of an electric race car.

Based in Israel, Eviation Aircraft is racing to complete development of its ‘Alice Commuter’ to be the first all-electric commuter plane in the skies. To do so, the company has incorporated 3D printing to speed up development and reduce costs.

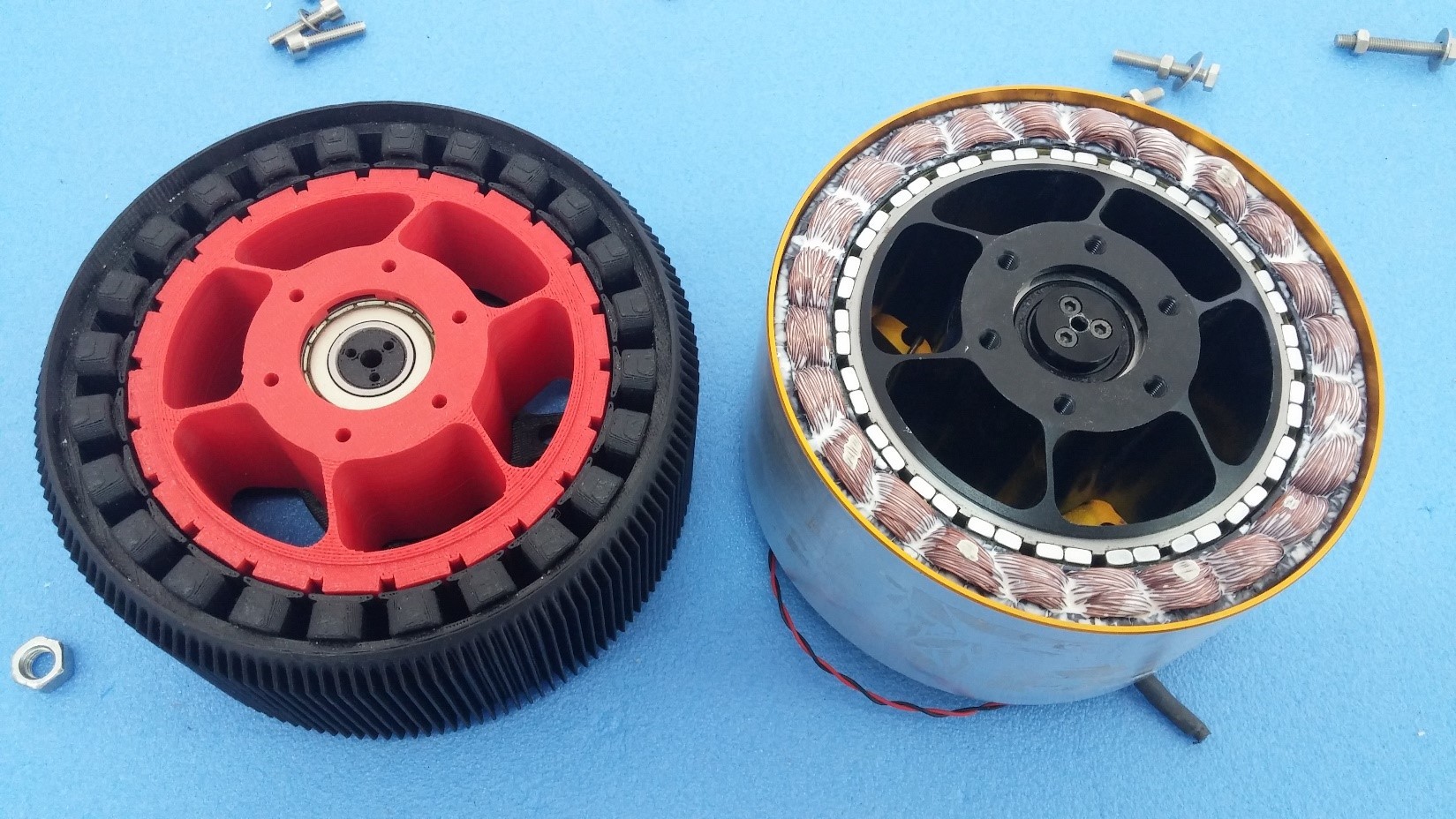

Constituting of Eindhoven University of Technology students, InMotion’s incentive to implement 3D printing is to reduce weight in all of its races. Using Materialise’s 3D printing services, InMotion has incorporated crucial metal parts in its IM/e racecar.

“Cost-effective and clean” flight

Eviation Aircraft’s Alice vehicle is designed to transport up to 9 passengers in mid-range flight travel. The company envisages the aircraft will be ideal for ‘on-demand’ air travel for short distances, with costs comparable to a train ticket.

Eviation founder and CEO, Omer Bar-Yohay, explains “Eviation aims to make regional air travel a cost-effective and clean option that rivals any existing form of transit today.” Bar-Yohay cites the trend of people working and commuting from further locations than ever and believes low-cost, eco-friendly air travel is the ideal solution.

To develop the Alice Commuter aircraft, Eviation harnessed a Stratasys Fortus 450mc production 3D printer. Stratasys is currently expanding its aerospace application and also recently partnered with Boom Supersonic to develop a supersonic aircraft. With the Stratasys 3D printer, Eviation was able to fabricate both prototype parts and important tooling. CEO, Omer Bar-Yohay details the benefits of the technology,

All in all, in two years of operation we have saved several hundreds of thousands of dollars with Stratasys 3D printing and I would estimate six months or more of workforce hours, which made this project possible.

Eviation 3D printed a prototype wing tip motor in just 20 hours using the Stratasys machine and now expect flight testing to begin in 2018 with aims of commercial availability by 2021.

Record-breaking electric racecar

InMotion, based at Eindhoven University of Technology (TU Eindhoven), is on a mission to create a racecar for the Le Mans 24-hour race. In order to do so, the team are demonstrating their electric technology in the IM/e racecar which is held together with 3D printed metal.

By reaching out to Materialise, the InMotion team were able to incorporate a lightweight titanium Y-joint which connects the wheel’s uprights to the chassis. Having 3D printed the part, InMotion tested the car at Zandvoort race track in the Netherlands and subsequently beat the electric lap record. The team achieved a lap which was 16 seconds faster than the previous lap record.

3D printing is more often deployed in motorsport to create prototype parts, however the possibilities for advanced geometries and lightweight designs are definitely attractive for the high-speed industry. Elsewhere at TU Eindhoven, researchers are developing technology to 3D print reinforced concrete bridges.

To stay updated with all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows the Eviation Aircraft Alice concept. Image via Eviation.