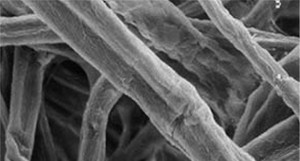

Last week the big news regarding 3D printable materials were about Laywoo-3D, a FDM filament created out of a wood/polymer composite which could produce amazingly realistic looking results – resembling actual wood. This week, however, things are taken to another level with the usage of actual cellulose as raw material for 3D printing.

This innovative approach was created by Aalto University’s students in Finland, who were challenged to come up with a solution to elevate the brand of Finnish wooden products to a similar status of the world famous French champagne. The project, suitably named Design meets Cellulose, targeted the dilemma of brandless bulk currently produced in the land of thousand lakes with a sense of optimism: “We should be able to brand the Finnish forest industry, because it has been left behind by the competition. The project involved brainstorming how the image could be polished and how resources should be allocated”, states Project Co-ordinator Jaakko Paloheimo from the Department of Forest Products Technology. Watch an ode to cellulose, the video created by the project team below.

In a multi-discipline project team, in this case consisting of students from engineering, forestry, arts, design and architecture departments, a consensus

Hopefully we will see this kind of unity also on a broader macro scale, where 3D printing will bring parties from all three sectors together in order to come up with something truly groundbreaking – and combining the benefits and creating synergy from ecological to financial aspects whilst doing the innovative dance of creation.

Source: Aalto University