Professor Yuehe Lin, assistant professor Arda Gozen and their team at Washington State University (WSU) have leveraged 3D printing to create a more effective glucose screening device. For use by people who suffer from diabetes, these microdevices have proven to be more sensitive and economical with materials than those produced using traditional screen printing. As such, direct ink writing (DIW) is discussed as a potential method for the development of cheaper, patient-specific biosensors.

Needle-free glucose monitoring

Currently, glucose monitoring is conducted by pricking the skin and analyzing a small sample of blood. Not only is this invasive, but the process is uncomfortable and often painful. Biosensors, by contrast, present a pain free alternative, as Professor Lin explains, “Our 3D printed glucose sensor will be used as wearable sensor for replacing painful finger pricking,”

“Since this is a noninvasive, needleless technique for glucose monitoring, it will be easier for children’s glucose monitoring.”

Attached to the skin, the WSU biosensor monitors glucose content in a person’s sweat rather than relying on their blood. While they can be made using traditional screen printing, 3D printing via DIW is providing a more promising alternative, as it has the potential to consolidate many parts of the production process, waste less material, and does not require cleanroom processing.

Flexible, multimaterial 3D printing

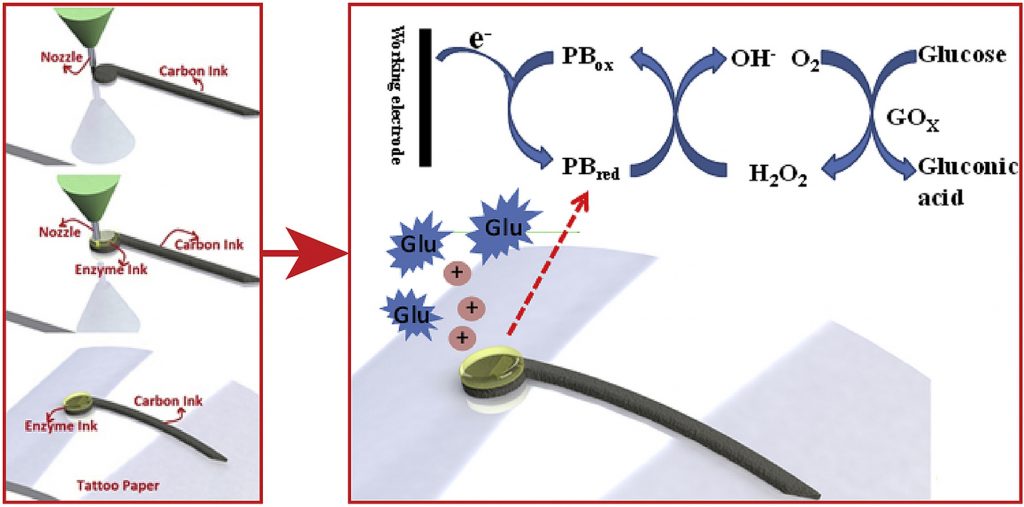

DIW is a material extrusion based 3D printing process, working with inks as the material feedstock. Recently, the method has proven suitable for processing Kapton, the “ultimate” polymer, and is suited to managing materials of varying viscosity, including electrical inks, and rubber-like stretchable inks. By using multiple nozzles, DIW can also be easily migrated to a multimaterial process.

WSU’s biosensors, which are no bigger than a thumbnail, are 3D printed from layers of carbon and enzyme ink. In this composition, the carbon ink acts as an electrode, and the enzyme ink is there to absorb glucose. As those levels fluctuate, the electrode can feed back the data to a computer – though this functionality is to be developed wirelessly in the future.

The devices are flexible, and could be transferred to the skin, fitting to the curvatures or the body. In addition, Gozen says, “3D printing can enable manufacturing of biosensors tailored specifically to individual patients.”

Sophisticating personal health monitoring

In the study, the 3D printed sensor is assessed alongside a screen printed device of similar specifications. According to conclusions “Results show that 3D printed electrodes have more uniform and defect free surface which has led them to be more sensitive to electrochemical sensing. The in vitro characterization of the 3D-printed glucose biosensors revealed their ability to detect micro-molar levels of glucose in the presence of common interfering chemical species.”

In addition, “3D printed biosensor exhibited better reproducibility, repeatability and long-term stability.”

In terms of material economy, the authors also believe that DIW is a “critical advance” toward substantially reducing the cost of these devices, and increasing “the sophistication of biosensors for personal health monitoring.”

They finish:

“Our future efforts will be aimed at realizing such a complete integration and using the packaged system in long term, in vivo glucose monitoring.”

The full article, “Micro additive manufacturing of glucose biosensors: A feasibility study” is published online in Analytica Chimica Acta journal. It is co-authored by Sepehr Nesaei, Yang Song, Yijia Wang, Xiaofan Ruan, Dan Du, Arda Gozen and Yuehe Lin.

Keep up with the latest 3D printing research by subscribing to our free newsletter, following us on Twitter and liking us on Facebook.

Launch your career in academia through 3D Printing Jobs.

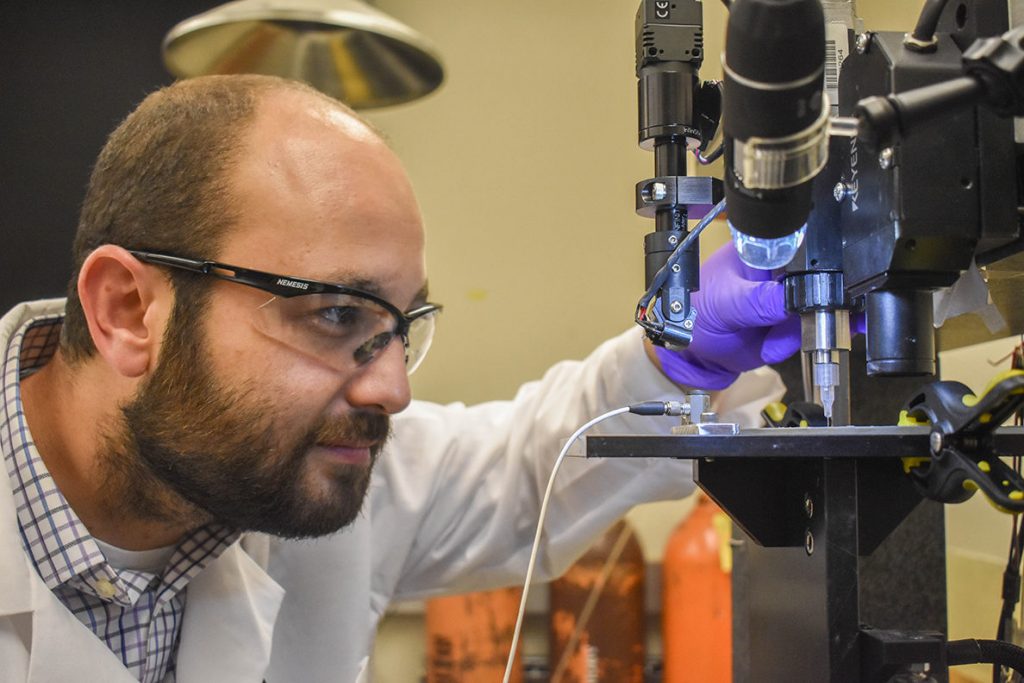

Featured image shows Arda Gozen, assistant professor, WSU School of Mechanical and Materials Engineering, in the Manufacturing Processes and Machinery Lab. Photo via WSU News