Arizona-based radar and antenna maker Lunewave, Inc. has announced $5 million in seed funding. The funding will be used to further develop the company’s proprietary radar and antenna technology.

The funding round was led by the automotive industry specialist investment fund Fraser McCombs Capital (FMC), Boulder, Colorado. The round also included investments from BMW i Ventures and Baidu.ventures.

Speaking about the investment co-founder and CEO of Lunewave, John Xin, said, “FMC and others bring deep experience across the global automotive and technology industry and we are looking forward to hiring top talent and accelerating development to meet demand from customers.”

The Managing Partner at FMC, Mark Norman, will also be joining Lunewave’s board of directors.

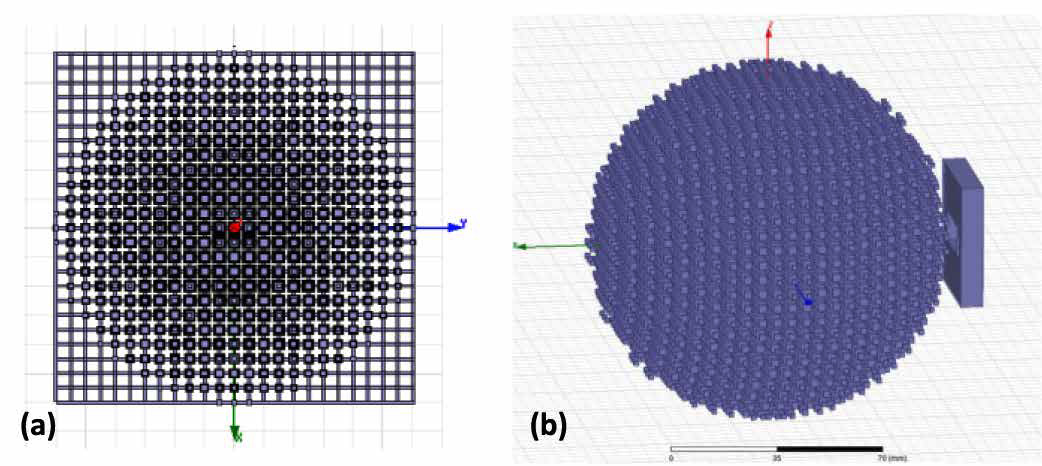

3D printed lens antenna

Lunewave is also an alumnus of URBAN-X, a New York-based accelerator for startups reimagining city life. In 2017 and 2018, respectively, Lunewave received National Science Foundation’s SBIR award (Phase I and Phase II).

On the success of Lunewave, the Managing Director of URBAN-X, Micah Kotch, said, “Lunewave has demonstrated the power of their product and their ability to innovate in the autonomous vehicle space in a way that offers significant value to global OEMs […] we couldn’t be more excited for the success of Lunewave and what is to come for the company.”

Lunewave’s Lüneburg 3D printed lens antenna is a microwave antenna with an insulator placed in front of the dipole to manipulate radiated energy. The Lüneburg lens antennas are custom made and give a 360-degree view. They can be used in autonomous cars, drones, satellites, and 5G communication.

3D printing Lidar and radar alternative

Autonomous vehicles can be limited by the use of Lidar and radar technology. These scanners can be costly and may also be poor performers in adverse weather conditions. Lüneburg provides a low-cost alternative to traditional sensor systems, with good results in poor weather conditions.

MIT researchers have also worked to find alternatives to Lidar and radar technology. Their solution was a 0.5 mm x 6 mm silicon photonic chip which can be integrated with the Lidar system.

Due to the complexity of the process of radar and antenna making, designers and manufacturers have opted 3D printing technology. 3D printed metal antenna maker, Optisys, created a 3D printed antenna, lighter and smaller than one made using traditional processes.

Last year, Interdisciplinary Science and Technology (NIIST), India, made a wearable antenna with 3D printing.

To catch the latest news on 3D printing, subscribe to our 3D printing newsletter, or follow us on Facebook and Twitter.

If you are thinking of starting a new career, visit our 3D printing job site.

Featured image shows a collection of Lüneburg lenses. Image via Lunewave