Bruce Paterson is the proprietor of Pattos Place, a world leading source for model cars – both slot cars and model replicas. The company has crafted detailed models of legendary cars such as Ferraris, McLarens, Vipers, Aston Martins and many more in the huge range that you can find at their online gallery. Mr. Paterson has created more than 1,500 different car styles and 9,000 different decal sets. Now this world leading model maker has started to use innovative 3D paper printing for slot cars that replicate legendary vehicles of racing lore.

Slot cars are remotely controlled model cars that are used to race each other along model tracks. Pegs underneath the cars fit into slots that guide them around the electrified circuit. Most enthusiasts race slot cars that are commercially available to buy via retail, some build theirs from scratch to create their own car bodies and mechanisms from purchased or sourced parts and materials. There are three common slotcarsizes: 1:24 scale, 1:32 scale, and the HO size 1:87 to 1:64 scale. These are commonly written as 1/24, 1/32, and so on. The cars are usually models of actual automobiles, though some are purpose-designed for miniature racing.

Mr. Paterson originally hand-carved his moulds. The model car bodies are made of PETG plastic, a material which everyone is familiar with due to its use in soda bottles and common food packaging. The process he used involved heating the plastic until it is suitably soft, then wrapping the softed PETG around a precise car-shaped mould. From there the material is allowed to cool, taking on its new permanent shape. In time Bruce perfected his art using traditional model making methods and earning a reputation for himself as a strong craftsman.

Then the skilled artisan heard about the time and effort saving benefits of 3D printing. It wasn’t long before he had moved on to experimenting with the technology and started to make his moulds from computer-aided designs. Bruce has been using 3D printing to craft his amazing slot car model replicas of legendary vehicles for some years now.

Bruce first set about using stereolithography 3D printing to create his model cars. It uses liquid plastic resin cured with ultraviolet light. For some time the benefits of this technology provided a more efficient way of producing his slot cars and scale models. In retrospect, and now having found a cheaper alternative in 3D paper printing, Bruce considers that using stereolithography was overly complex and expensive for his business needs. A set of four moulds – one each at 1/24, 1/32, 1/43 and 1/64 scale – would cost over $250.

Mr. Paterson was about to close shop, but then he came across 3D paper printing by Mcor Technologies with some of the lowest operating costs of any additive manufacturing technology. Using ordinary business paper, the paper is bonded together, the output printed model is tough and durable as what is essentially wood. A set of four moulds cost around a quarter of the mould sets from created by stereolithograpy saving over $180 a set.

He now reflects: “3D printing got very, very expensive because of the plastic materials I had to buy. Not only can I stop worrying about the cost of moulds, the thermoformed bodies are coming out truer than ever. Paper holds its shape perfectly. Distortion is a well-known but rarely discussed problem with plastic-based 3D printing, which involves heating and cooling. The Mcor process is also clean and green, and I love the results, and my customers love the results.”

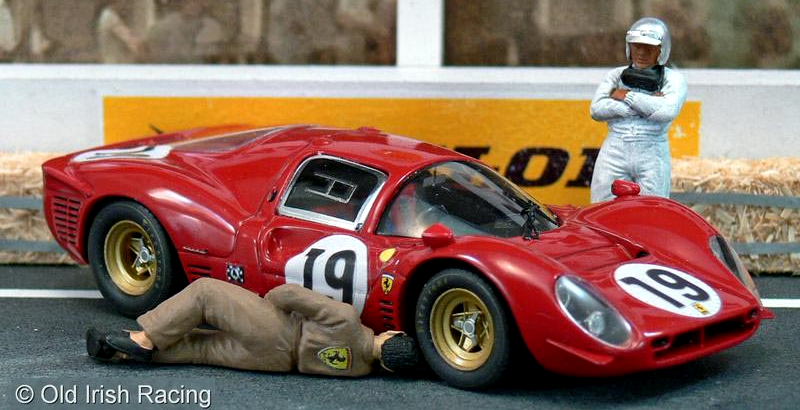

You can find the many amazing examples of Pattos Place model cars and slot cars at their online gallery here. It really is worth a browse to see just how exquisite these miniature automobile classics really are — and just what hard work, talent and 3D printing technologies such as stereolithograpy and ‘3D paper printing’ really are capable of.