3D printing service provider 3D Metalforge has completed the testing and commissioning of a range of polymer 3D printers that will see it expand its offering of high-end polymer applications within the defense, maritime, and oil and gas sectors.

The new printers expand the firm’s fleet of polymer machines to 33, capable of printing in up to 25 different materials, and form part of its strategy to meet customer demand for more high-end, high-performance polymer capabilities.

“We always ensure we have a wide range of materials available to help us meet client demand and we are very pleased to add these customized polymer printers to our range,” said Matthew Waterhouse, 3D Metalforge Managing Director.

“We firmly believe there will be significant increased demand for high performing polymers as the AM industry grows and matures.”

3D Metalforge’s expanding capabilities

3D Metalforge already has a comprehensive portfolio of SLM, DED, MJF, and FFF 3D printers, in addition to various post-processing machines. Using these technologies, the company offers a range of production, design consultancy and related training services to clients within the energy and defense, maritime, and oil and gas industries.

Back in 2017, 3D Metalforge opened its Additive Manufacturing Centre (AMC) in Singapore, an end-to-end production facility specifically designed to target the marine, oil and gas, and construction sectors. The firm has since signed two memoranda of understanding (MoU) with the Maritime and Port Authority of Singapore, and established a new FFF 3D printing farm in Singapore.

This year, 3D Metalforge has continued to grow its capabilities, fueled by going public on the ASX in March in a move that saw the company raise AUD $10 million in capital. Following its IPO, the company established a new factory in Texas before opening what it claims is the “world’s first” AM port facility, equipped with the firm’s Hybrid Wire Arc print (W-HAAM) 3D printer.

Around the same time, 3D Metalforge also became a certified pump impeller supplier for Flowserve, enabling it to supply a client with a $5.5 billion US market capitalization and strong APAC user base. Most recently, the service provider leveraged its 3D printing capabilities to manufacture and supply heat exchanger parts to one of oil and gas conglomerate Shell’s offshore facilities.

Increasing polymer capabilities

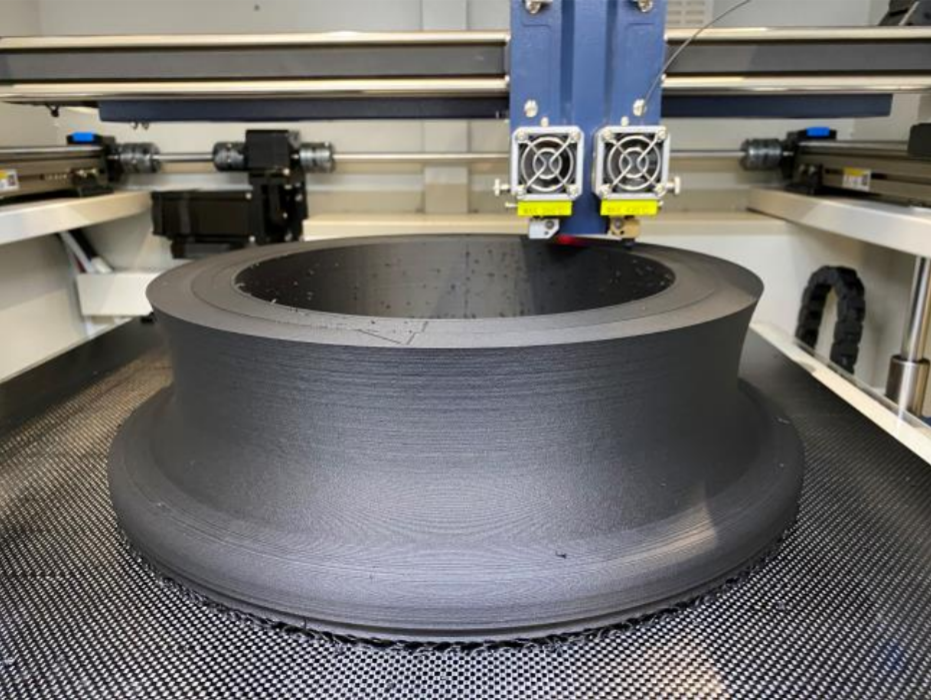

3D Metalforge has now completed the testing and commissioning of a range of customized polymer 3D printers in a move that will see the firm expand its offering into high-performance polymers like PACF and PEEK.

The firm predicts increasing demand for these particular materials from customers in the defense, maritime, and oil and gas sectors due to their unique properties. For instance, PACF exhibits higher stiffness and chemical resistance, while PEEK is characterized by its excellent chemical and thermal resistance.

While the company has not revealed the brands or companies behind the printers it has tested and commissioned, it will install three machines with a print size of 600 x 600 x 600 mm, and four machines with a print size of 400 x 300 x 300 mm. Over the next two months, five more of the larger format printers will be installed across 3D Metalforge’s global locations, taking the firm’s fleet of polymer printers to 33.

The service provider’s expanded polymer capabilities will enable the production of enduring fully-dense parts in up to 25 different materials, including increasingly sought-after high-performance polymers.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows 3D Metalforge printers printing a large format part in PACF. Photo via 3D Metalforge.