Canadian tissue engineering company 3D BioFibR has raised over $3.52 million in seed financing.

This funding will be used to expand the company’s facilities to include a climate controlled manufacturing cleanroom, and to bring its collagen fiber products to market. Valued at $26 billion, the tissue engineering market is currently growing at a compound annual growth rate of 35%.

This announcement follows the launch of the company’s two new collagen fiber products for 3D bioprinting, μCollaFibR and CollaFibR 3D scaffold. These new offerings are produced using 3D BioFibR’s proprietary fully automated dry-spinning process. This is said to be the only process capable of producing high-quality, diameter-controlled collagen fibers at a commercial scale.

“We are grateful for this investment as it accelerates our plan to meet the increasing demand from tissue engineers for a premium 3D collagen scaffold that optimizes cell growth,” commented 3D BioFibR CEO Kevin Sullivan. “Our goal is to make it incredibly easy for researchers to grow their cells in environments that actually resemble human tissues.”

Where has this funding come from?

The financing round was led by Invest Nova Scotia with matching investment from Build Ventures. Returning investors Concrete Ventures and Globalive Capital also provided additional investment during this round.

“We see great market potential for 3D BioFibR’s premium collagen products for use in 3D cell culture and tissue engineering applications,” commented Patrick Keefe, general partner of Build Ventures. “We are excited by the speed and skill with which they are building out their manufacturing capabilities.”

“3D BioFibR’s best-in-class collagen fibers have the potential to make them a dominant player in the cellular scaffolds segment of the tissue engineering market,” added Dr Lidija Marusic, interim Vice President of Investment at Invest Nova Scotia. “We’re pleased to continue to back the team behind such a novel platform technology with many future applications.”

3D BioFibR has also received additional financial support from the Government of Canada, which is providing a repayable $528,920 contribution through the Atlantic Canada Opportunities Agency (ACOA). This funding is being provided through ACOA’s Regional Economic Growth through Innovation (REGI) program. This contribution is set to aid in the creation of a new wet lab and cell culture facility.

“The Government of Canada is committed to helping Atlantic entrepreneurs like 3D BioFibR scale-up because when local businesses succeed, they create jobs and solutions that benefit all Canadians,” commented Andy Fillmore, Parliamentary Secretary to the Minister of Innovation, Science and Industry and Member of Parliament for Halifax, on behalf of Ginette Petitpas Taylor, Minister of Official Languages and Minister responsible for ACOA.

Additionally, 3D BioFibr is receiving advisory services and research and development funding of up to $391,949 from the National Research Council of Canada Industrial Research Assistance Program (NRC IRAP). This support will be used to further the development of the company’s automated collagen fiber manufacturing system.

3D BioFibr’s collagen fiber offerings

Last month, 3D BioFibR announced the launch of μCollaFibR (pronounced micro-CollaFubR) and CollaFibR 3D scaffold. These new off-the-shelf products are said to offer significant advantages for tissue engineering and tissue culture applications.

The company claims that these products are “best in class” from a strength, diameter, and quality perspective, accurately recreating the natural appearance, structure, and function of collagen fibers. 3D BioFibR’s dry-spinning manufacturing process is also said to be at least 3,600x faster than competing processes. This makes the company’s collagen fibers more accessible to a growing number of bio-medical applications, allowing companies to scale their 3D bioprinting manufacturing processes.

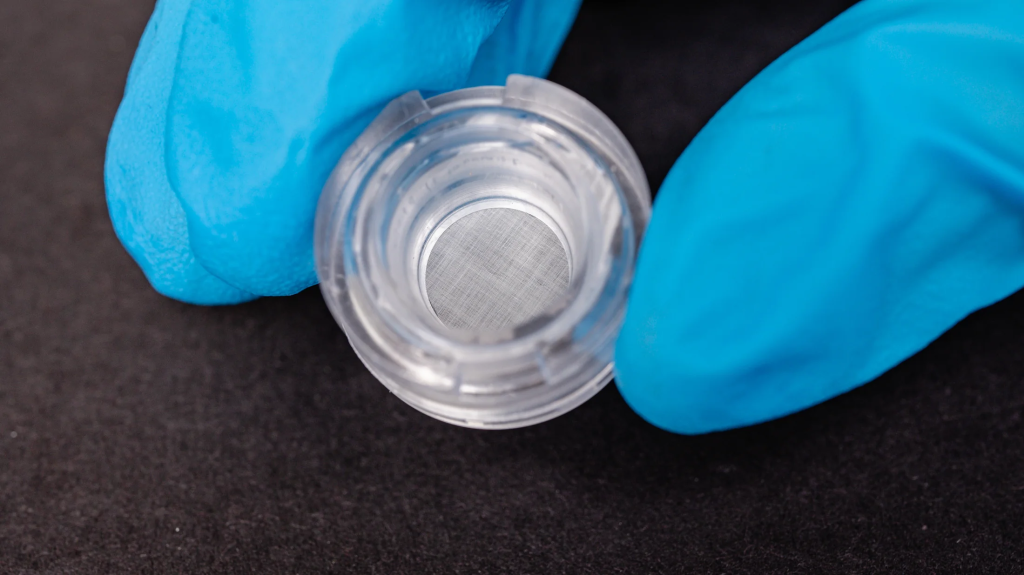

μCollaFibR is a bioink additive for laboratory 3D bioprinting of tissue and organ models. This product mimics the body’s cellular scaffolds, acting like a biological rebar in bioinks used to 3D print living tissue. Thus, once added to bioinks, μCollaFibR enhances the mechanical durability of 3D printed tissue. This allows multiple cell layers to be 3D printed layer-by-layer, facilitating the production of highly functional tissue and organ models.

On the other hand, CollaFibR 3D scaffold is designed for use with 3D cell cultures, enabling researchers to study cellular reactions in a more physiologically relevant environment than traditional 2D cultures. By using GMP type 1 collagen, this product produced a consistent collagen fiber matrix. This more closely resembles the biochemical and biomechanical properties of natural cellular environments.

Investment in 3D bioprinting

3D bioprinting is certainly a growing area within additive manufacturing, and is attracting wide ranging investment. Earlier this year it was announced that Biopharmaceutical equipment supplier Sartorius had acquired a 10% stake in 3D bioprinting innovator BICO. Alongside the share acquisition, worth €45 million, the two companies also announced a partnership which will see them collaborate on R&D initiatives and the development of ‘digital solutions for cell line development workflows.’

Last year, Spanish 3D bioprinting company Regemat 3D also announced substantial investment, raising over €500,000 in equity crowdfunding. Through this funding round, the company gained backing from over 500 investors, supporting plans to accelerate the marketing and development of its proprietary 3D bioprinting technology. The company has claimed that, with further R&D, its portfolio could enable the creation of functional, personalized 3D printed tissues.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows μCollaFibR by 3D BioFibR. Photo via 3D BioFibR.