Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

After finalizing a 64-month lease for its new US headquarters and manufacturing facility in Ohio, AML3D has announced an AUD$2.24 million investment to advance its ARCEMY Increase Deposition Rates (AIDR) project.

Leveraging its proprietary Wire-arc Advanced Manufacturing (WAM) technology, this initiative aims to extend and maintain AML3D’s technology advantage in the global market. Funding for the AIDR project includes a $1.12 million grant from South Australia’s Economic Recovery Fund (ERF), matched by contributions from AML3D. Supported by the South Australian Government, this project is scheduled to commence in August 2024 and will run for 15 months.

“Having the South Australian Government support the development of the next generation of our ARCEMY technology is expected to keep AML3D and South Australia at the forefront of advanced manufacturing in the years to come,” said CEO Sean Ebert.

AIDR to create local opportunities and eco-friendly manufacturing

The investment is expected to create four new advanced manufacturing and software development jobs initially, highlighting the project’s contribution to local employment and skills development. AML3D’s ARCEMY systems are currently employed in supplying metal 3D printed components to defense sectors in Australia and the US, including support for the US Navy’s submarine industrial base.

Key aspects of the project include sourcing metal 3D printing consumables from local South Australian suppliers and conducting verification testing at an approved National Association of Testing Authorities laboratory in Australia. The AIDR project aims to enhance manufacturing efficiency, reduce energy consumption, and minimize waste, thereby positioning South Australia as a globally significant hub for advanced metal manufacturing and technology innovation.

Successful completion of the project is expected to further strengthen AML3D’s competitive edge in the global market while reinforcing the advanced manufacturing ecosystem both in South Australia and nationally. According to the company, the development of a multi-robot, twin-wire ARCEMY system through the AIDR project is anticipated to drive productivity gains, innovation, and enhanced global competitiveness in the advanced manufacturing sector.

Recent milestones for AML3D

A month before securing this grant, AML3D signed a contract with Toolcraft Australia to supply a 6-part nozzle assembly valued at AUD$0.35 million for an Australian Government Defense Science and Technology Group (DSTG) project. After successfully delivering a 4-stage nozzle assembly, demonstrating the benefits of its WAM technology with faster production times than traditional methods, AML3D expanded the contract to include an additional 2 stages of an Aluminium ER5183 nozzle assembly.

Weighing about 1230 kgs and measuring over 3.6 meters, these components were anticipated to be produced soon, leveraging AML3D’s proven operational excellence from previous nozzle assemblies. Initial delivery of the first two stages is expected this fiscal year, with the remaining four stages scheduled for FY25.

On a financial basis, AML3D reported a record second consecutive quarter of cash receipts, totaling AUD $2.46 million as stated in the Quarterly Activities Report and Appendix 4C for the quarter ended December 31, 2023 (Q2 2024). This highlighted a 4.6% increase from the previous quarter. The company attributed this growth to its successful US ‘Scale Up’ strategy, aimed at addressing supply chain challenges for the U.S. Department of Defense (DoD), particularly the US Navy’s submarine industrial base.

In 2023, this strategy yielded over $12 million in orders, according to the company. AML3D continues to maintain robust US sales pipelines and anticipates a strong FY2024 revenue performance. Additionally, the company expanded its global presence with new contracts in Australia and secured an Indian process patent for its WAM technology.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

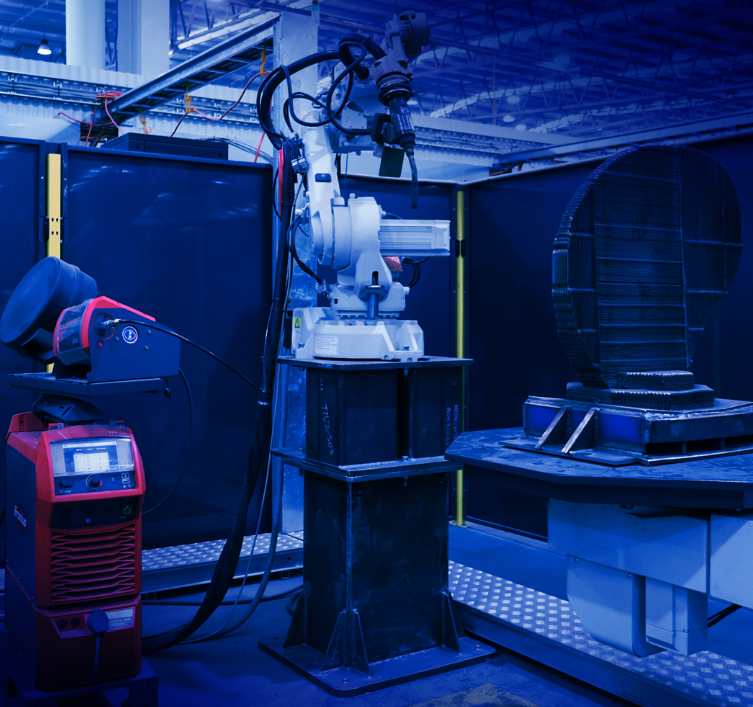

Featured image shows a typical ARCEMY metal 3D printing system. Photo via AML3D.