Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

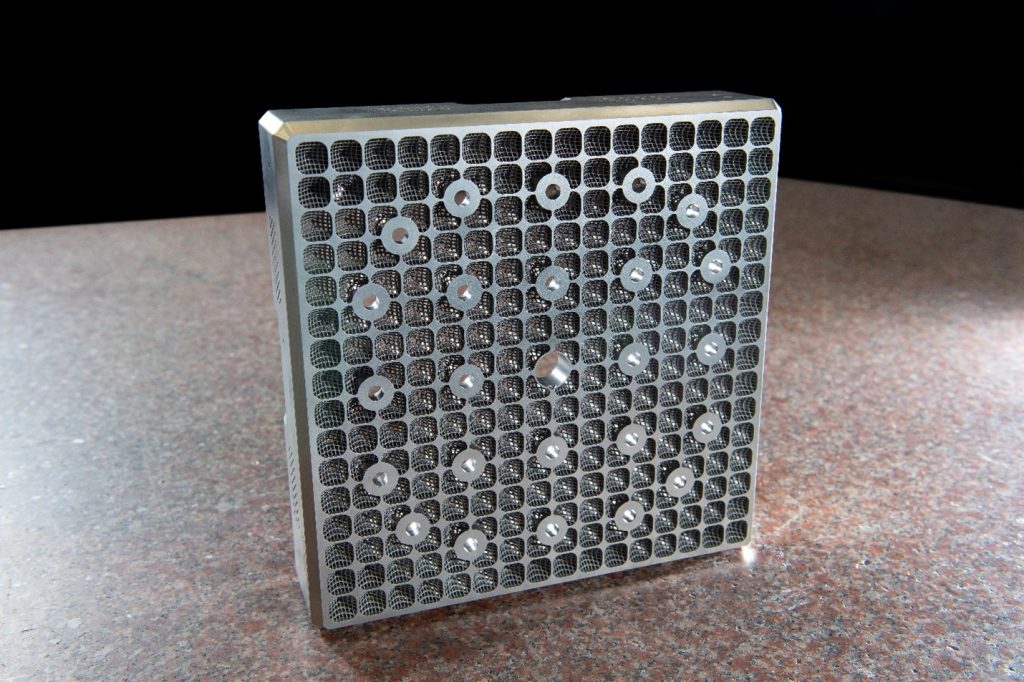

Westinghouse Electric Company has developed what it claims as first-of-its-kind filtering bottom nozzles focused on improving debris capture and fuel endurance.

Four lead test assemblies incorporating new nozzles were delivered to Alabama Power’s Joseph M. Farley Nuclear Plant, operated by Southern Nuclear. These assemblies aimed to target debris fretting, the primary cause of leaks in Pressurized Water Reactor (PWR) fuel assemblies.

According to the company, AM played a crucial role by allowing for enhanced design flexibility, which effectively reduced the diameter of debris capable of entering the reactor. During testing, the additively manufactured components exhibited a notable 30% increase in resistance to debris.

“Our additive manufacturing technology is allowing us to achieve breakthrough performance with an immediate positive impact for our customers,” said Tarik Choho, Westinghouse President of Nuclear Fuel. “This significant technology innovation for PWR reactors mitigates the risk of leakage in the fuel rods due to the accumulation of debris, strengthening the safety and efficiency of our customers’ operations.”

Westinghouse AM efforts in nuclear power generation

Westinghouse has been active in AM research within the nuclear industry since conducting the first material irradiation study of AM nuclear components in 2015. Two years later, Westinghouse announced it would install an additively manufactured thimble plugging device in a commercial reactor, becoming a pioneer in this field. Crucial for holding nuclear fuel and preventing debris release, this device utilized AM 316L stainless steel and non-AM 304.

Supported by U.S. Department of Energy (DoE) funding, Westinghouse researched cost-effective 3D printing methods for nuclear components, including powder bed fusion and direct energy deposition. The initiative also addressed safety concerns, studying neutron radiation effects on AM-produced zirconium alloys for light water reactors.

Back in 2022, Westinghouse’s Sweden division installed the world’s first 3D printed nuclear fuel debris filters named StrongHold AM filters in nuclear power plants across Scandinavia. Designed by working with Finnish company Teollisuuden Voima Oyj (TVO) and OKG in Sweden, these filters were approved for end-use and integrated into unit 2 of Finland’s Olkiluoto plant and unit 3 of Sweden’s Oskarshamn plant. These filters play a crucial role in preventing foreign debris from damaging fuel rod cladding, ensuring uninterrupted power generation, says the company.

Crossover between AM and nuclear sector

As noticed previously, AM is transforming the nuclear sector through rapid prototyping, custom component production, and specialized material development for nuclear applications. It enhances supply chain resilience, reduces waste, and enables cost-effective maintenance and repair of critical nuclear equipment, all under stringent regulatory standards for safety and reliability.

In an interview last year, Dr. Xuan Zhang of Argonne National Laboratory and Niall O’Dowd, Founder of Phase3D, highlighted their collaboration focused on advancing AM for nuclear applications.

Phase3D played a critical role with its real-time inspection technology, which detected anomalies during the 3D printing process to ensure quality and reliability in nuclear reactor components. This capability addressed challenges such as material qualification and operational safety, aiming to enhance efficiency, reduce waste, and promote sustainable manufacturing practices within the nuclear industry

Back in 2020, Oak Ridge National Laboratory (ORNL) partnered with the Tennessee Valley Authority (TVA) and Framatome, a nuclear fuel supplier, to develop and install the first-ever 3D printed fuel assembly brackets for Browns Ferry Nuclear Plant in Alabama. This achievement, announced in 2020, is part of ORNL’s Transformational Challenge Reactor (TCR) program, which aims to make nuclear energy deployment in the US faster and more cost-effective.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows an additively manufactured bottom nozzle. Photo via Westinghouse Electric Company.