Israel-based 3D printer manufacturer Massivit 3D introduced the Massivit 3000, its new large-format 3D printer, to the 3D printing market at TCT 3Sixty 2024.

According to Avi Cohen, the company’s VP for Sales and Marketing, this new system is an affordable, high-speed addition to the large-scale 3D Printer market. In an interview at the Massivit booth, Cohen stated that the Massivit 3000 can 3D print large parts “30 times faster than any other system on the market.”

He also shared insights on the total addressable market for the large-format sector, and how the Massivit 3000 is poised to exploit growing demand for technology that can 3D print big parts fast.

Incorporating Massivit’s unique Gel Dispensing Technology, the new 3D printer is optimized for the marine, automotive, furniture, visual communications and themed entertainment sectors.

With prices starting at less than €200,000, Massivit has already received interest for its newest product. Cohen revealed that the company recently sold one of the 3D printers to a customer in the industrial sector.

TCT 3Sixty was the first additive manufacturing trade show to feature the new Massivit 3000, marking its introduction to the 3D printing industry.

The Massivit 3000: affordable and fast large-format 3D printing

Boasting a substantial 3D print volume of ~1.2 x 1.5 x 1.8 m, the Massivit 3000 is ideal for users wanting to fabricate large parts in a single 3D print job.

3D printing speed is a key selling point of Massivit’s new offering, facilitated by the company’s proprietary Gel Dispensing Technology. In this process, photopolymer gels are extruded at high speeds before being rapidly cured into solid layers under UV light.

This enables “very fast” 3D printing, according to Cohen. A 1.8-meter tall ice-cream cone model was 3D printed in around five hours at TCT 3Sixty, “30 times faster than any other technology.”

A broad range of polymer and acrylic materials can be fabricated through the Gel Dispensing approach, including those with high strength and translucent characteristics. These materials’ unique rheology and 0.8 mm layer thickness facilitate high-fidelity 3D printing and intricate surface details.

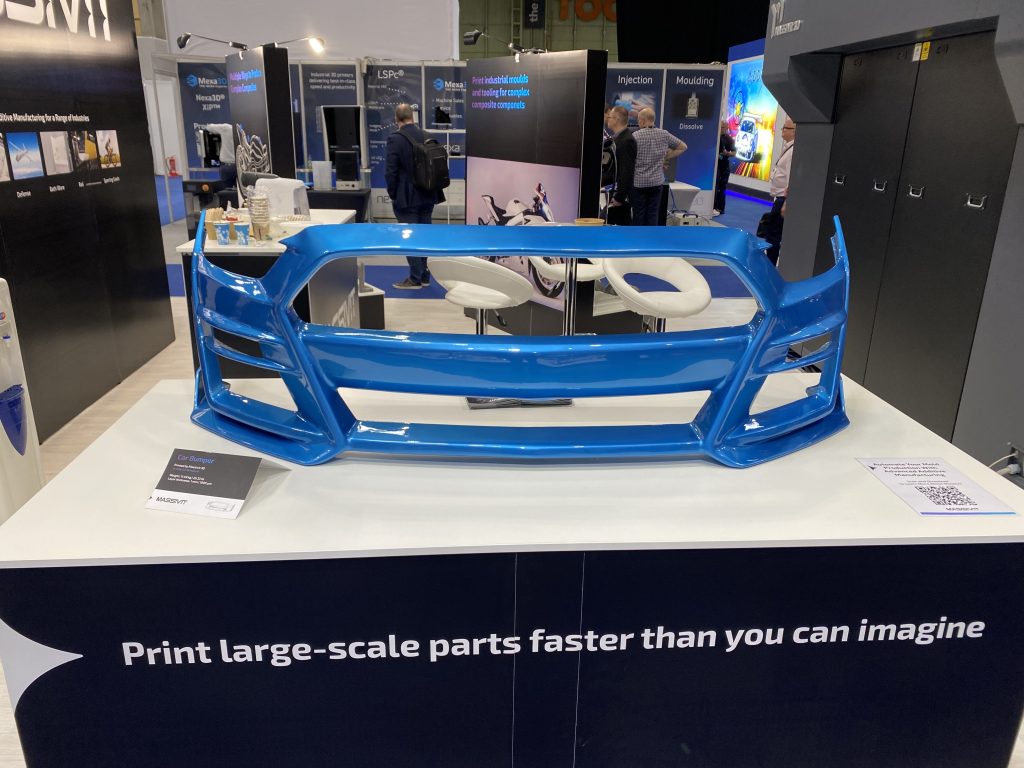

As such, the Massivit 3000 is adaptable to various end-use applications, ranging from hollow light features to personalized car bumpers and functional boat structures. A fiberglass coating can be added post-3D printing to increase the strength and durability of these large-scale, end-use parts.

The company’s unique extrusion process also enables the Massivit 3000 to produce complex geometries without support structures. “We print hollow,” explained Cohen, who emphasized that this approach significantly reduces the material requirements for large parts, enabling cost and weight savings.

Indeed, the Massivit 3000 was designed with affordability in mind. Cohen emphasized its “budget-friendly” price point, which will allow many more people to exploit the benefits of Massivit’s technology.

He believes this competitive pricing differentiates the new system in a growing sector. According to Cohen, the total addressable market for large-scale additive manufacturing is “huge,” encompassing hundreds of machines each year and an increasing number of new applications.

Cohen is confident in Massivit’s ability to exploit this expanding market, proclaiming that the company is well positioned to “conquer the world” of large-format 3D printing.

Technical specifications of the Massivit 3000

| 3D Printing Technology | Gel Dispensing Technology |

| 3D Print Heads | 1 3D Printing Head |

| Material Systems | 1 Material System |

| 3D Print Volume | W x L x H: 145 x 111 x 180 cm / 57” x 44” x 70” |

| 3D Printing Resolution | 0.8 mm / 1.0 mm / 1.3 mm |

| Motion System | Servo Motors |

| 3D Printing Material | Dim 90, Dim 100, Dim 300 |

| Workflow and Software | Massivit Smart SlicerSoftware on machine: Massivit proprietary front-end software. Input format: STL |

| System Dimensions | W x L x H: 3 x 2.2 x 2.8 m / 119” x 97” x 110” |

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows Avi Cohen, VP Sales and Marketing at Massivit, and the new Massivit 3000. Photo by 3D Printing Industry.