Desktop 3D printer manufacturer Zmorph has announced the launch of its latest all-in-one system – the Zmorph Fab.

The announcement comes amid a major rebranding from the Polish manufacturer, one that aims to shift the company more towards the professional (and industrial) markets in line with Zmorph’s maturation as a brand. Behind the scenes, the changes are backed by substance too, as the company recently established several distributor partnerships, acquired the HBOT 3D brand, and closed a $1.3M financing round in early 2020. As an added bonus, Zmorph has also unveiled plans to launch a whole new industrial printer, the i500, in Q1 2021, and more on the horizon.

Bartosz Lanc, CMO of Zmorph, states: “It’s the single most important moment for the Zmorph brand since its founding back in 2012. We evolved from a dynamic startup into a reliable brand and partner for professionals in over 120 countries. The rebranding will enable Zmorph to further expand into the global market, accomplish global growth objectives and to strengthen the professional image.”

Referring to the collaborative synergy with HBOT’s R&D department, Zmorph CEO Maciej Nawrocki adds: “We are now working on a product which addresses professional expectations in terms of reliability, repeatability, and reproducibility, as well as serviceability. This will be an offer where we deliver a full ecosystem.”

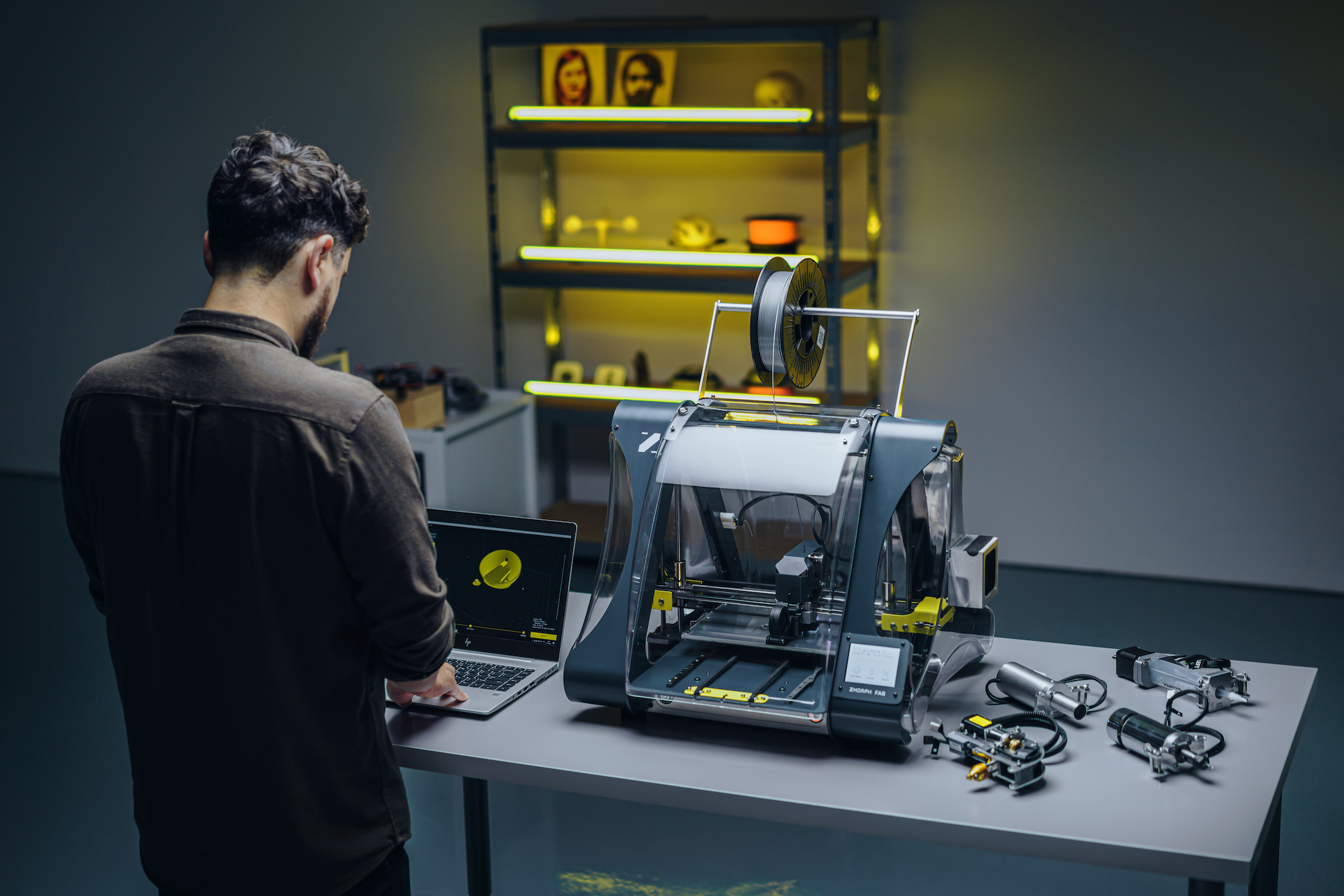

The Zmorph Fab

The Zmorph Fab claims to be an easy-to-use all-in-one desktop 3D printer, and is largely based on the company’s previously released Zmorph VX with a plethora of upgrades. As such, its key selling point is the interchangeable tool head assembly, which enables FDM 3D printing, CNC machining, laser engraving, and laser cutting – all on the same machine.

The new Single Extruder Toolhead, the 3D printing aspect of the system, is capable of a maximum nozzle temperature of 250°C. It houses a set of filament runout sensors designed to pause and resume prints, and also features a redesigned cooling system packing a new cooling fan with improved airflow.

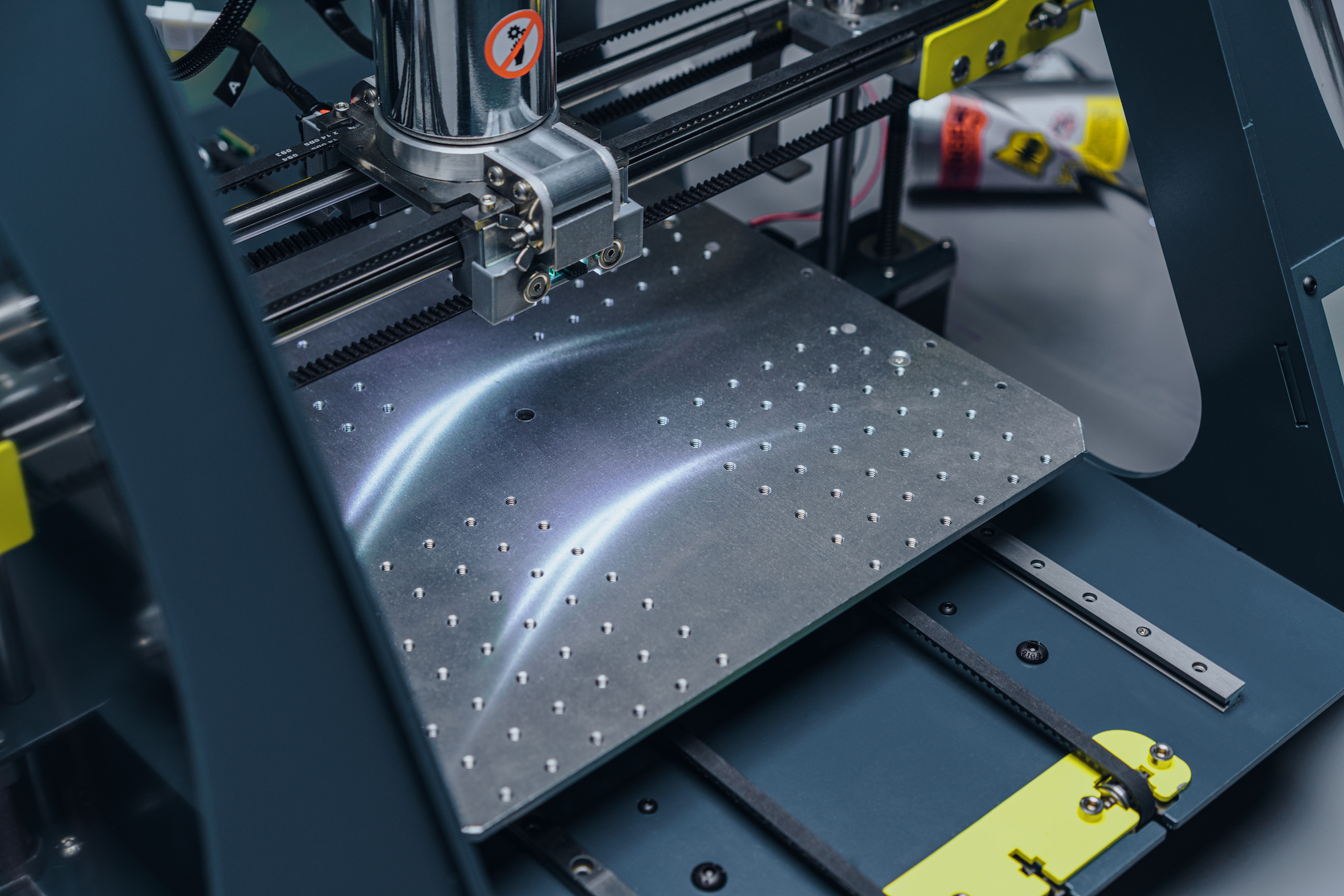

Zmorph has also updated the machine’s CNC capabilities, and offers a new CNC worktable purpose-built for easy and stable material mounting. Using the CNC tool, users can machine down wood blocks, polymer blocks, and 3D printed parts for tight tolerances and higher quality surface finishes. The Fab is able to automatically detect which tool is currently in use via its SMART Toolheads System, and tool changing is now quicker than ever.

Safety and slicer upgrades

The machine itself features a build volume of 250 x 235 x 165mm, and is fully enclosed. To improve its safety during indoor operation, the company has equipped the Fab with a HEPA/Carbon filtration system, ensuring the fumes and particles emitted during printing and laser engraving are nothing to be concerned about.

As the cherry on top, Zmorph has also updated its proprietary slicer, Voxelizer, to better accommodate users’ multi-tool workflows. The company has developed a number of new 3D printing presets that have been adjusted to enable faster printing without the loss of part quality. Furthermore, the software now provides STEP operations, allows users to change milling bits mid-CNC process, and features path visualization functionality.

Eliza Wróbel, Product Manager at Zmorph, adds: “Zmorph Fab is made to be easy-to-use and reliable right out of the box. The latter is crucial for a product that operates three different workflows and is meant to work 24/7. The new Zmorph Fab’s features are based on customers’ and business partners’ feedback, making it the most advanced yet easy-to-use all-in-one 3D printer on the market. With new features like the HEPA/Fumes Filter, the Zmorph Fab is a great addition to modern classrooms, FabLabs, workshops, and design labs.”

Technical specifications and pricing

Below are the technical specifications for the Zmorph Fab. The machine is available in two bundles: the All-in-One set ($3999) which comes with the 3D printing, CNC, and laser toolheads; and the 3D printer set ($2959) for customers that are exclusively interested in the machine’s 3D printing capabilities. Visit the Zmorph online store or any of the authorized resellers to order now.

| Build volume | Up to 250 x 235 x 165mm (toolhead dependent) |

| Layer resolution | 0.05 – 0.4mm |

| Material diameter | 1.75mm, 3mm |

| Nozzle diameter | 0.3 – 0.6mm |

| Leveling method | Automatic and manual |

| Connectivity | USB, ethernet, SD card |

| Max nozzle temperature | 250°C |

| Max bed temperature | 115°C |

| Filter | HEPA/Carbon |

| Software | Voxelizer |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Zmorph Fab all-in-one 3D printer. Photo via Zmorph.