The 2021 3D Printing Industry Awards shortlists are open for voting, have your say now.

Having teased the imminent launch of new products last week, 3D printer manufacturer Zaxe has today unveiled three new 3D printers – the xlite+, Z2 and Z3.

Alongside listening to feedback from its customers, the company has applied the knowledge and experience it has gained over the past five years to build on the R&D and design of its machines to make them even more accessible and easy to use.

“We have deeply focused on the design process of our 3D printers and designed them in the simplest way to give you the best experience,” says Baki Gezgen, Founder of Zaxe. “Our new series is based on the modular design system for better production, and we created a product family with this concept.”

The growth of Zaxe

Since Zaxe’s story began in 2015 with the building of a prototype 3D printer in Gezgen’s garage, the company’s subsequent products have won the support of the likes of Aydonat Atasever, one of the founders of Turkey’s largest c-commerce firm, and other high-profile names such as Nevzat Aydın, KVK, and Emre Akıncı.

“Since 2015, we have developed and produced many 3D printers to adequately know how to get to today,” says Gezgen. “In 2015, we took the first step of Zaxe firmware. We developed our slicer software to control each of our 3D printers from WiFi. We also changed the SD care print meta to print to USB flash drives or direct WiFi. These developments were the seeds of our vision at the time.”

Over the next few years and after receiving further investment, Zaxe ramped up its R&D activities to begin dominating the Turkish 3D printing market. In 2019, the firm launched its Z Series of 3D printers, and began micro-exports to the US, Canada, and Azerbaijan, among others. As a result, the company’s 3D printer portfolio has grown to accommodate its X1, X1+ and X2 3D printer range, its Z1 and Z1+ line of machines, and its xDesktop software and filaments.

The latest launches enlarge Zaxe’s 3D printing hardware offering further, featuring a whole host of new features and upgrades to improve ease of use and open up the accessibility and affordability of additive manufacturing.

Bringing new features to the market

“We want to make 3D printing accessible and easy to use,” Gezgen states, as he discusses the new features of Zaxe’s latest machines. “This year, we combined our clipper firmware with our Zaxe firmware and used all the features of our core XY design so we can print even faster with the new Z series.”

With its new 3D printers, the company is seeking to solve the common problem of nozzle clogging and short machine lifetimes. “That’s why we make all our 3D printers compatible with the E3D ecosystem,” he continues. “In this way, we adapt our structural architecture to E3D updates and new modules.”

After listening to feedback from its customers, Zaxe is also giving users the freedom to use any slicer software with its new machines, and has added the OctoPrint option to its firmware to allow customers to make use of the open source interface with its 3D printers.

“This year, we gathered all our knowledge and experience that we have gained since 2015 in our new products,” adds Gezgen. “We offer much more robust, much faster, very innovative printers to change the standards by making innovative solutions accessible with our next generation 3D printers. We tried to build on users’ feedback and requests, and built our R&D on it. We have designed a long-lasting technology of impeccable quality.

“As a company that gives importance to R&D, we compensated by combining our design line with hardware, software engineering and solid mechanics.”

Developing the new 3D printer series

Zaxe’s new 3D printers are based on a modular design that complements the user behavior of its customers and simplifies machine operation.

“We created a metal skeleton body with exceptional stability that combined all components and design shells, then isolated all electronics from the print area to keep both running at their most efficient performance,” says Gezgen. “Our mechanical system is innovative and robust, shaped like a heavy cubic body to give it an industrial look. The complexity of the mechanics and software system has been simplified by design to allow users to focus more on the printing experience.”

As a result, Gezgen believes the new machines have a friendlier and more approachable appearance, each complemented by the addition of a large, easy-to-use 7-inch display screen with a completely new interface.

“We placed the capacitive screen end-to-end in the middle of the black glass, giving you deep focus communication with the printer,” he says. “We created a process as clear as possible and made the printing area visible from many angles, while hiding the mechanics and complex structure inside. We used tempered glass on the front doors for better visibility and we aim to keep users safe in all conditions.”

A wide-angle camera has also been integrated into the new machines to enable users to monitor and control their prints remotely, and the printers have also been installed with a new fan system to aid temperature control and airflow.

“Having the freedom to use different materials is a prominent feature,” Gezgen continues. “We understand the importance of this freedom and work for compliance. The newly-designed reel holder accommodates reels of different sizes and is compact for out-of-use situations. Ease of use and compactness are always our main criteria and we aimed to reflect it in all parts of the design, such as the hepa-filter, extruder cover, and adjustable spool holder.”

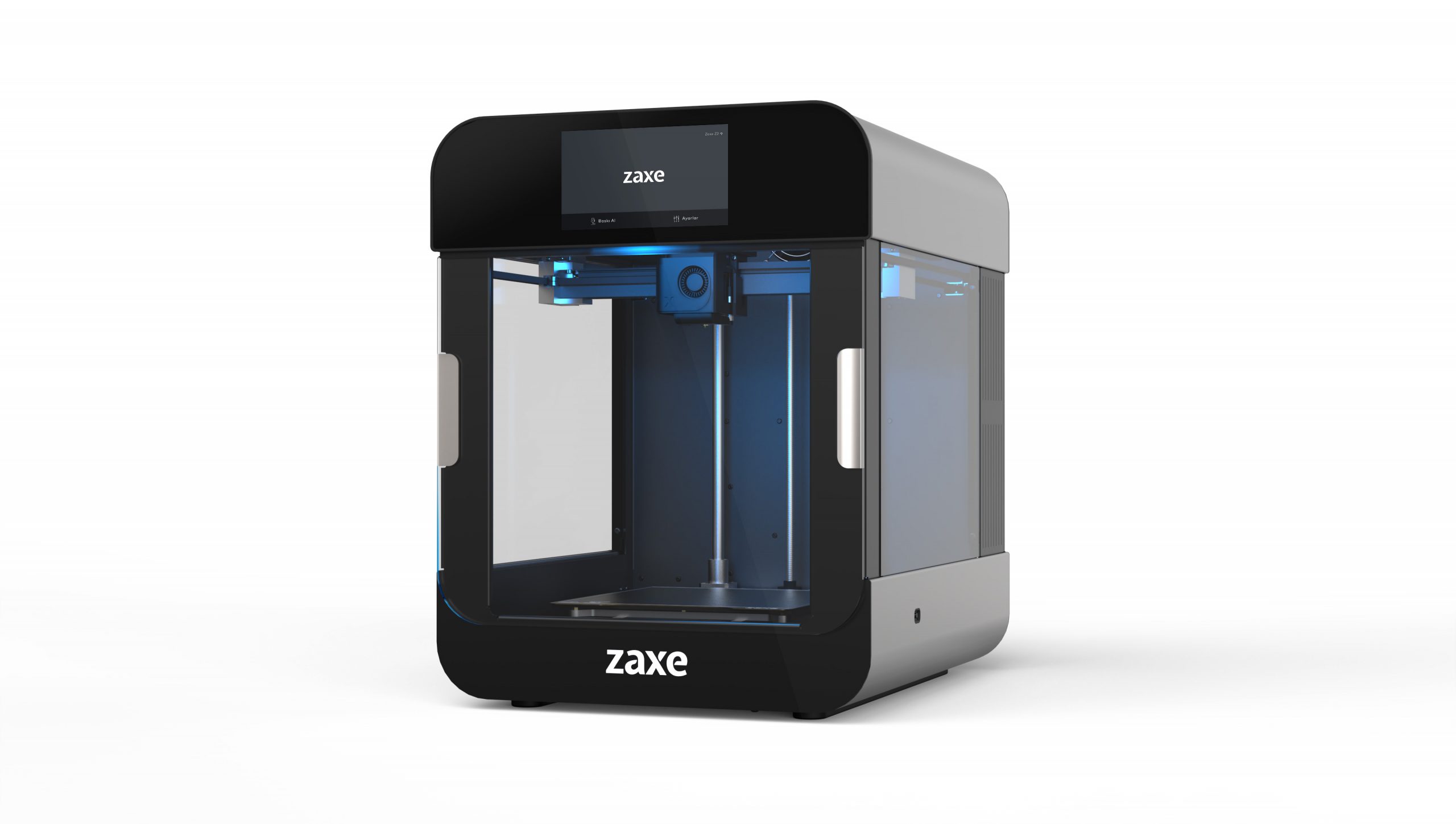

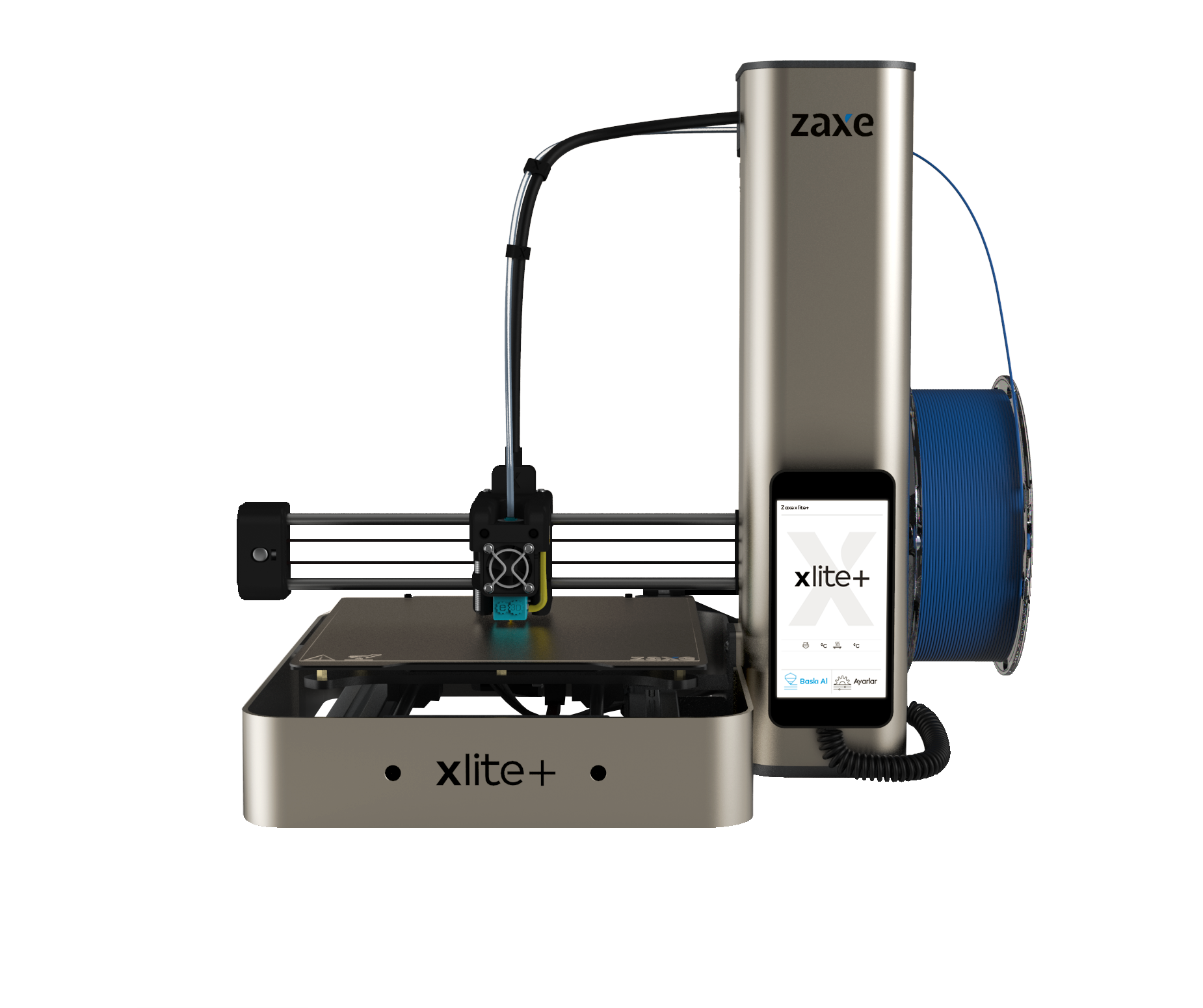

The Zaxe xlite+

Zaxe’s X series of 3D printers are suitable for use within the education sector, where students can leverage the machines’ capabilities to increase their creativity and shift their focus from consumption to production.

The Zaxe xlite+ builds on the features of its xlite predecessor, offering a 22 x 23 x 20 cm printing surface and fully automatic print calibration. As Gezgen mentioned, the machine is compatible with “all materials” thanks to the E3D customized titanium print head.

In addition to a 5-inch touchscreen for easy print monitoring, the xlite+ enables WiFi printing and smooth operation due to its integration with the Zaxe Cloud and next-generation X cards. Models can also be removed from the printer’s table more easily thanks to its flexible printing surface.

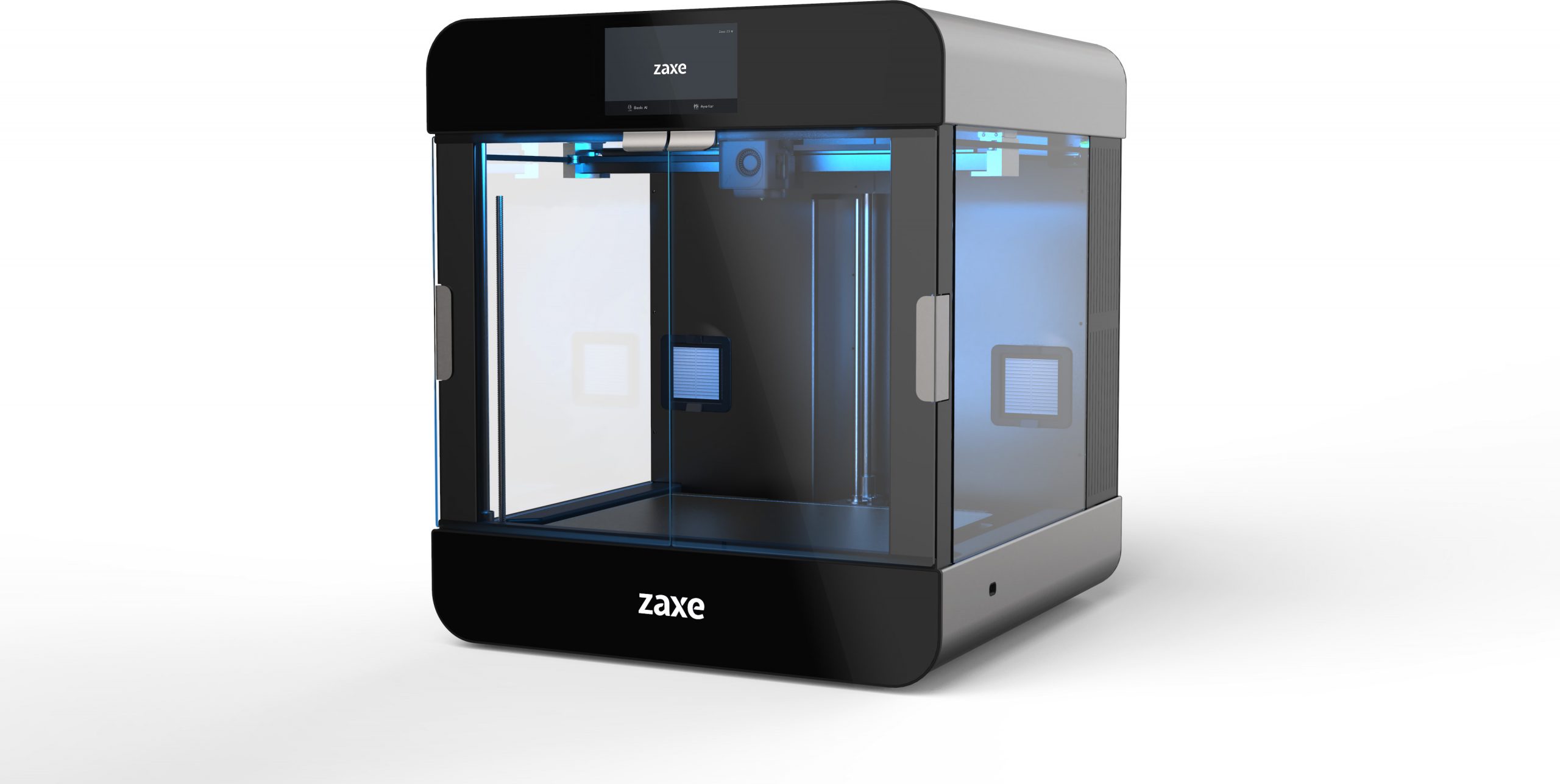

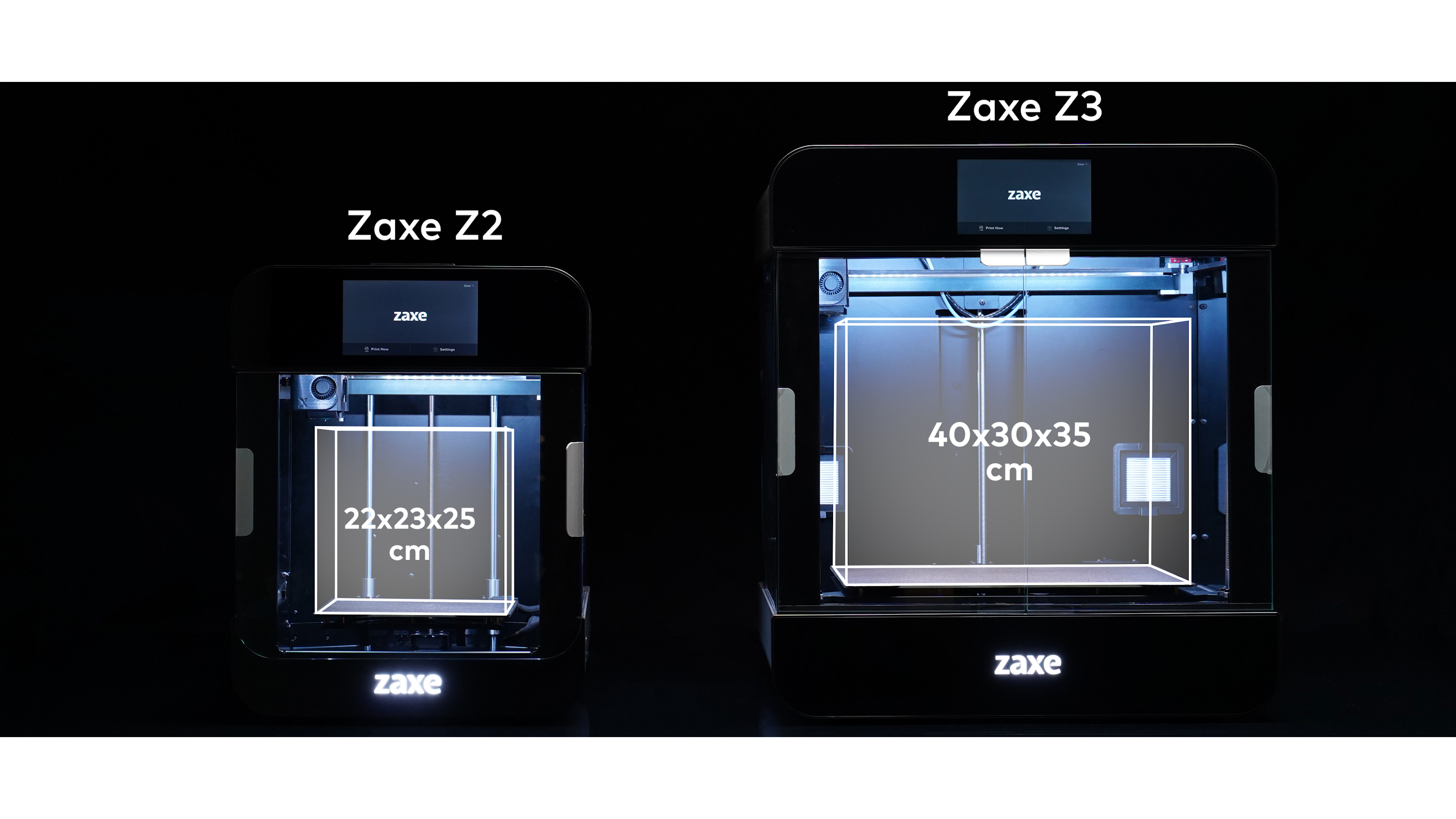

The Zaxe Z2 and Z3

Zaxe’s Z series of 3D printers are engineered mainly for industrial use, particularly for R&D within sectors that require high tolerances. The range can also be leveraged by professionals to rapidly develop, prototype and print their own designs, while hobbyists can make use of the Z series to repair broken parts and create new objects and models at home.

The first new addition to Zaxe’s Z Series of 3D printers, the Z2, delivers high speed printing of up to 300 mm per second hand-in-hand with the company’s new printing software. The machine itself features a print area of 22 x 23 x 25 cm and, like the Xlite+, is equipped with an E3D customized titanium printhead that is compatible with an array of different materials.

A larger 7-inch touchscreen provides users with an easy-to-use interface with which to manage their prints, while glass-front doors enable easy monitoring of the production process. The Z2 also features a flexible printing surface to make it easier to remove models once printing is finished, while next-generation ‘Z cards’ provide a more secure and hassle-free printing experience for Zaxe’s customers.

The Zaxe Z3, meanwhile, offers many of the features of the Z2 but with a larger print area spanning 40 x 30 x 35 cm. Operating at the same printing speed, the Z3 doesn’t sacrifice speed during the production of larger parts, opening up a wider range of potential applications to Zaxe’s customers.

“One of our most important goals is to move technology forwards by making it sustainable and create a completely user-oriented ecosystem,” concludes Gezgen. “Since 2015, we have developed and produced lots of 3D printers to grant us enough know-how to reach this day.

“Today, we are at the point where we can offer our high-standard technology at affordable prices.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows the Zaxe Z2 and the larger volume Z3 3D printers. Image via Zaxe.