French large-scale 3D printing firm XtreeE has announced the global deployment of three new connected 3D printing units.

Operated by partners in Switzerland, the United States, and Japan, these sites bring the number of deployed 3D printing units up to 12. This forms part of XtreeE’s ongoing strategy to build a worldwide network of more than 50 3D printing units by 2025.

The company, which was founded in 2015, is working to raise funds to support this goal. This comes after the successful completion of a €1.1 million funding round in 2017, and a €1 million round in 2018. Vinci Construction, Shibumi International (a fully-owned venture fund of Gülermak Heavy Industries and engineering firm Thornton Tomasetti) and Holcim France, have all invested in XtreeE.

XtreeE claims to be accelerating the development of its network of connected 3D printing units, to enable the efficient production of custom structural building elements. The inauguration of 6 additional units is planned by the end of 2023.

XtreeE’s “printing-as-a-service” platform

XtreeE’s “printing-as-a-service” platform provides customers with a catalog of certified products. This includes small standardized construction elements with high replicability, like reservation boxes and formwork elements, and complex parts such as bridge segments and beam nodes.

Digital assistance tools for architectural design and 3D printing parts are also included with this platform. According to XtreeE, these tools allow manufacturers and designers to develop their projects with sustainable and optimized construction systems. “Dynamic support” from the XtreeE team is also offered with this platform. This includes training in parametric modeling and in the use of robotized 3D printing technology.

Additionally, the “printing-as-a-service” platform connects project owners to a global community of architects, designers, engineers, manufacturers, and builders. XtreeE customers automatically become part of this community and ecosystem.

According to ExtreeE, the key challenge is to provide the Architecture, Engineering, and Construction (AEC) industry with novel construction systems which meet the growing demand for industrialized, cost- and time-effective, solutions.

“Our model is based on a ‘multi-local’ ecosystem, which allows us to efficiently produce custom structural elements anywhere in the world,” commented Alban Mallet, co-founder and managing director of XtreeE. “The challenge is to print as close as possible to the construction sites, and we support our partners locally with our digital platform and our design-build services.”

XtreeE large-scale 3D printing

XtreeE has so far demonstrated the viability of its technology through more than 40 projects. These range from architectural elements, infrastructure, and interior and exterior furniture.

In 2020 it was announced that XtreeE was part of a consortium awarded a design-build contract from France’s Plaine Commune Grand Paris, to construct a 40-meter pedestrian footbridge made from 3D printed structural concrete.

Designed for the 2024 Olympic games, the consortium sees XtreeE work alongside civil engineering firm Freyssinet, Levigne and Cheron Architects, computing and artificial intelligence (AI) firm Quadric, and building materials specialist LafrageHolcim. XtreeE claims that this project will further validate their 3D printing technology, paving the way for familiar projects to be deployed around the world.

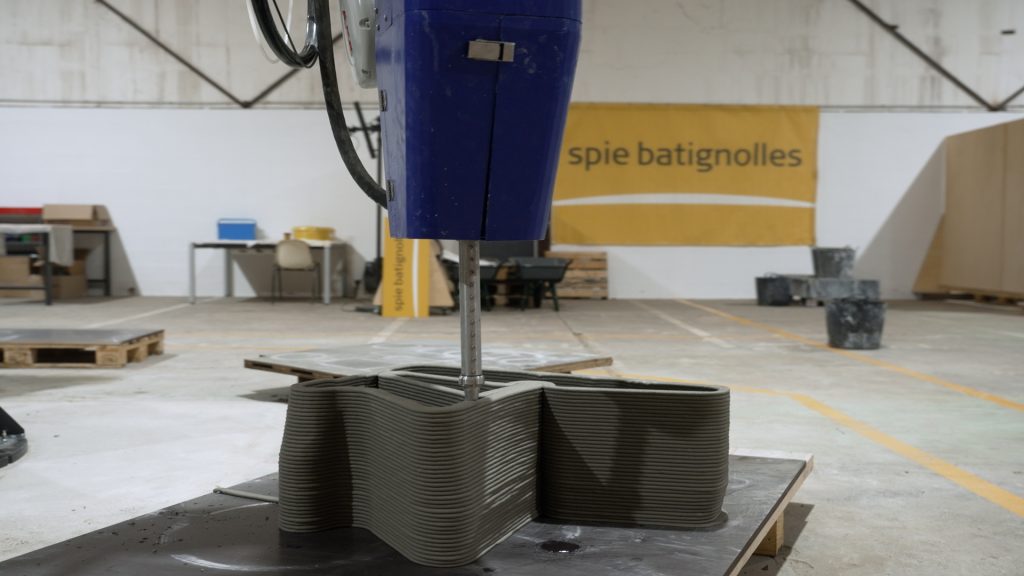

Following this latest announcement, XtreeE has now globally deployed 12 3D printing units. One such unit is that of French construction company Spie Batignolles group, who opened an additive manufacturing workshop in Ollainville in 2021. The company is now looking to further industrialize with their new dedicated product offering “EmPrinte,” and will open two new workshops by the end of the year.

Large-scale additive manufacturing

XtreeE is not the only company to offer large-scale 3D printing capabilities. Metal additive manufacturing company Rosotics recently unveiled the first complete prototype of its new Mantis 3D printer. This large-format metal 3D printer can manufacture components up to 30 feet in diameter at a rate of 45kg of material per hour. Set to launch to market in October, Rosotics claims that the Mantis can produce items larger than any other 3D printer on the market.

Elsewhere, in 2021 it was announced that the world’s longest 3D printed concrete pedestrian bridge, spanning 29 meters, had been constructed in Nijmegen. Rijkswaterstaat, the Dutch Directorate-General for Public Works and Water Management, partnered with TU Eindhoven, Witteveen+Bos, BAM, and Weber Beamix to 3D print the bridge. The key aim of this project was to demonstrate the design and sustainability benefits offered by concrete 3D printing.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a close-up of an XtreeE large-scale 3D printer. Photo via XtreeE.