Laser Powder Bed Fusion (LPBF) 3D printer manufacturer Xact Metal has announced the addition of two new machines to its economical ‘XM’ portfolio.

Priced at just $65,000, the cheaper of the firm’s latest systems, the ‘XM200C,’ is designed to provide SMEs with a stripped-back, accessible means of adopting LPBF for the first time. The more powerful $90,000 XM200G, meanwhile, packs dual-lasers with a configurable wattage and spot size that, according to Xact Metal, arms users with “industrial speed and performance at an affordable price.”

“XM200G printers tailor to customers, starting their entry into metal 3D printing in various applications, including product development, tooling manufacturing, metal powder-bed research and education,” said Juan Mario Gomez, CEO of Xact Metal. “Xact Metal aims to further expand the use of metal 3D printing in multiple industries including aerospace, automotive and general manufacturing.”

Xact Metal’s accessibility mission

Founded in 2017, Xact Metal is on a self-proclaimed mission to “change the perception that additive manufacturing is only for capital-rich companies.” To accomplish this, the firm says it has developed a process which combines LPBF with “a breakthrough technology” in a way that enables users to access metal printing’s manufacturing speed and part quality benefits, but at a more affordable price.

Alongside its XM200C and XM200G systems, the firm has also integrated this technology into its upcoming ‘XM300C’ machine, which at 254 x 330 x 330mm, packs the largest build volume of all its printers to date. Set to launch in Q4 2022, the unit will be available in two or four multi-laser configurations, that are said to be capable of creating industrial-grade parts that don’t need debinding or sintering.

With regards to Xact Metal’s current portfolio, it now markets its XM200C and XM200G machines, as well as a related software, materials and services offering, that has allowed it to attract clientele varying from MAHLE and Medtronic to the U.S. Army, and it continues to seek out new applications for its accessible metal 3D printing product range.

The XM200C: economical metal AM

Built to enable as many manufacturers to take advantage of LPBF as possible, the XM200C incorporates an economical-but-serviceable compact design. Powered by Xact Metal’s proprietary ‘Xact Core’ high-speed gantry system, the machine essentially works by redirecting lasers using a series of light, simplistic mirrors above a powder bed on an X-Y axis.

In doing so, the machine avoids the need for any complex rotating galvanometer mirrors or F-theta lenses, while managing to maintain a constant laser angle across the entire build plate, and providing a simplified gas flow over the powder bed.

The system also features a bulb-shaped recoater design, which spreads powder like a blade, enabling it to deal with out-of-plane growth before ploughing on with production. On the flipside, if so desired, the device can be fitted to the machine’s lid as well, allowing it to be removed from the build chamber altogether, in a process that Xact Metal says is “easy” and allows for replacement or adjustments.

Elsewhere, the XM200C sports an easy-to-use 7” touch screen and two internal cameras that provide users with real-time monitoring capabilities, while the entry-level system boasts strong material compatibility too, including the ability to process powders such as stainless steels, maraging steels and superalloys as well as certain bronzes, coppers, aluminums and titaniums.

A configurable next-gen XM200G

The second-generation of Xact Metal’s XM200G machine may share a number of features with its smaller sibling, but its core architecture differs considerably from that of the XM200C. For a start, the higher-spec printer uses a galvanometer system to move laser beams over a powder bed, in a way that not only expedites part production, but provides it with the ability to support multiple lasers simultaneously.

In practise, this means that adopters can deploy two lasers at once, with either a 100% overlap area using a 100 µm spot size, or a 66% overlap and 50 µm spot size. This, in tandem with the machine’s 100-400W laser and water-cooled galvanometer customization options, make it configurable for specific applications, whether they be in R&D or end-use automotive and industrial manufacturing.

Unlike the XM200C, Xact Metal’s beefier XM200G also features an integrated powder handling system, potentially making it ideal for those seeking to enter serial production, while according to Gomez, its larger 150 x 150 x 150mm build volume and rapid 12 to 16 cc/hr print speed make it better suited to addressing lead-time intensive applications.

“The XM200G family is ideal for printing parts where high-performance applications and print speed are critical,” explains Gomez. “The introduction of the XM200G is another example of how Xact Metal continues to combine the requirements of metal powder-bed fusion and breakthrough technology to establish a new level of price and performance for additive manufacturing.”

Technical specifications and pricing

Below are the technical specifications for Xact Metal’s $65,000 XM200C and $90,000 XM200G 3D printers. Those interested can find out more about the machines via the company’s store page, where they can also request a quote if desired.

| XM200C | XM200G | |

| Buid Volume | 127 x 127 x 127mm | 150 x 150 x 150mm |

| Laser Type | 100W Yb fiber laser | Dual 100W, 200W or 400W |

| Precision Optics | Spot size > 20 microns | 50 or 100 μm |

| Materials | Al, Ti, Cu, steel, superalloys | Al, Ti, Cu, steel, superalloys |

| User Interface | 7” touch screen | 18.5” touch screen |

| Electricals | VAC Single Phase, 50/60 Hz | 1.5 kW, 2.0 kW Peak |

| Dimensions | 610 x 610 x 1,295mm³ | 650 x 780 x 1,930 mm³ |

| Weight | 205kg | 425kg |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

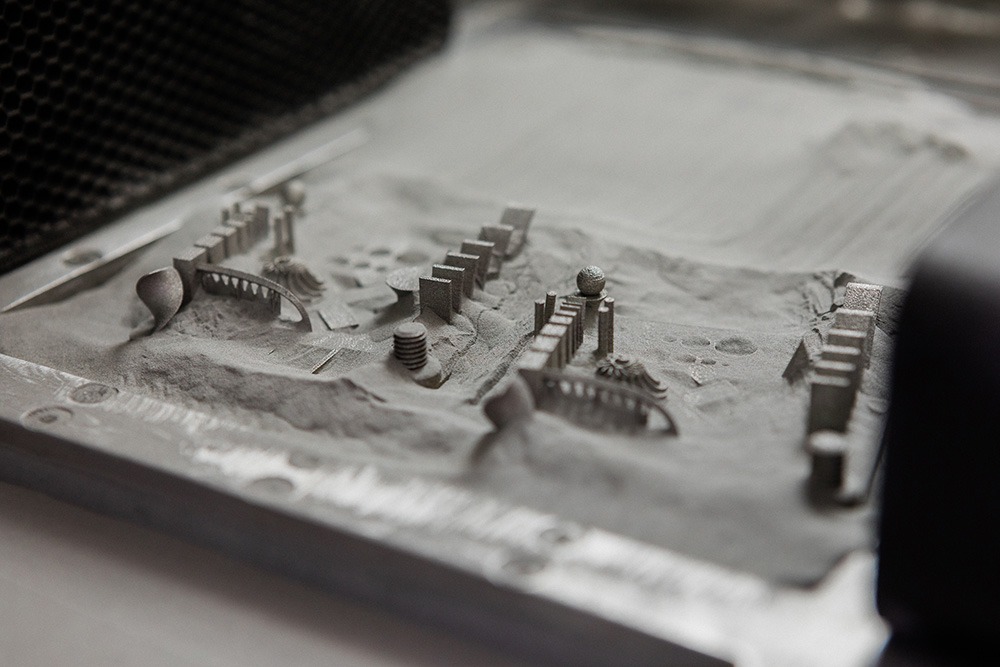

Featured image shows Xact Metal’s new XM200C 3D printer. Photo via Xact Metal.