ASTM International, a worldwide technical standards organization, has announced Wichita State University’s (WSU) National Institute for Aviation Research (NIAR) as a new strategic partner for its Additive Manufacturing Center of Excellence.

Earlier this year, ASTM International and founding partners NASA, EWI, and Auburn University, established the Additive Manufacturing Center of Excellence within EWI’s North American facility and Auburn’s Samuel Ginn College of Engineering in Alabama.

Now, NIAR has joined the consortium to accelerate certification for aerospace 3D printing materials.

“Building on its strengths, NIAR will lead efforts to qualify additively-manufactured materials and to further strengthen relationships with key aerospace regulators worldwide,” said Dr. Mohsen Seifi, Director of Global Additive Manufacturing Programs at ASTM International.

“Leveraging their expertise in R&D, we will develop much-needed standards that will significantly enhance certification in aviation and other industries. We’re thrilled to have the NIAR team on board.”

Accelerating additive manufacturing in the aerospace sector

NIAR is an industry-focused research institute at WSU, which hosts numerous aerospace engineering programs. The institute has previously aided Stratasys with the certification of its Fortus 900mc Aircraft Interiors Certification Solution system through repeatability testing of complex parts.

With its experience, NIAR will engage in the center of excellence’s R&D activities, education and workforce development efforts. The institute will also lead programs to ultimately enable the 3D printed customizable parts and components for spacecrafts, thus improving production and supply chain efficiency. Dr. John Tomblin, WSU Vice President for Research and Technology Transfer stated:

“We’re proud to be the first strategic partner in this globally-recognized center of excellence that will help build the technical foundation for the future of additive manufacturing. The center is attracting an array of leading industry players to the table to speak with one voice and make an impact.”

MTC joins ASTM International’s Center of Excellence

Coventry’s Manufacturing Technology Centre (MTC), was also been selected by ASTM International earlier this year, to be the first non-founding partner of its Additive Manufacturing Center of Excellence.

The MTC’s role within the consortium is to improve the standards of research and development and build industry gaps within additive manufacturing on an international scale.

For updates on this projects and more, sign up to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

On the lookout for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

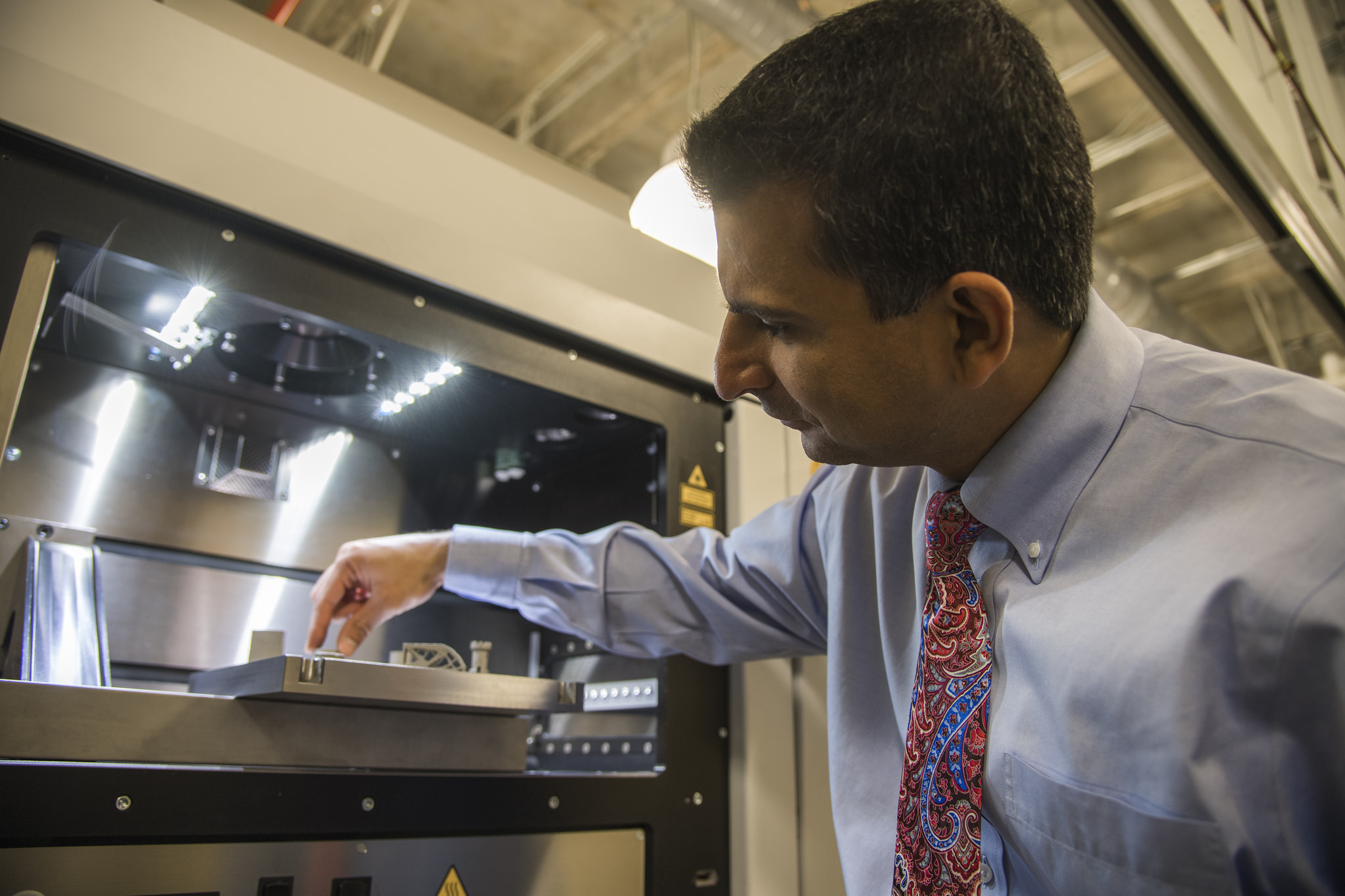

Featured image shows metal 3D printed samples at Auburn. Photo Auburn University.