Polish 3D printer company ZMorph, which Shane has covered in previous articles on 3DPI, certainly seems to be mixing it up a bit, and the company certainly caused a stir on the show floor of the 3D Printshow in London last week. This is because the company was demonstrating the keen aesthetics and the broad functionality of this personal fabrication machine.

Since its launch in 2012 the ZMorph team has been working hard on the R&D of both the hardware and the software that enable its desktop fabrication machine — so called because of the exchangeable tool heads that make it much more than a typical desktop 3D printer. It does perform that operation of course — with multiple extruder options for multiple material options. The USP of this little machine is absolutely versatility, and ZMorph have been ramping up that versatility with the introduction of new tool heads and new software at an increasing rate. They have recently been adding the new tool heads at a rate of one a month Przemek Jaworski told me at the show last week. Przemek is the

CEO & Founder of ZMorph, and further explained that these releases are coming off the back of a great deal of work behind the scenes working with customers and incorporating feedback.

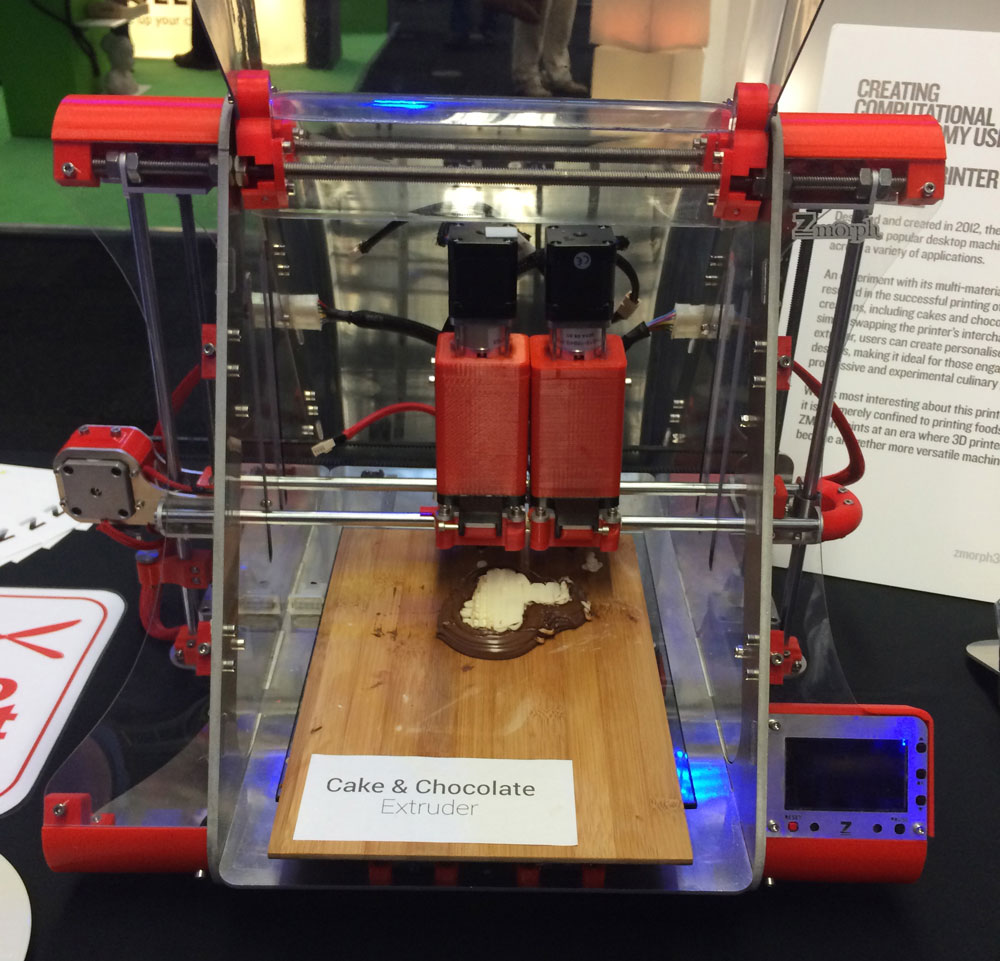

In terms of 3D printing, the tool heads include extruders for 1.75mm and 3mm filament, as would be expected. In addition there is a dual extruder option, as well as options for extruding alternative materials for ceramics and food materials (cake mixture and/or chocolate). Indeed, the latest dual extruder option is for the food materials, and it was on show in London for the first time — in the kitchen section of the show floor. The idea being that users can print two food stuffs simultaneously to create original shapes and flavours. According to Przemek, there has been a lot of interest from Patisseries and bakeries.

Other tool heads that have been developed for ZMorph are the ability to mount a Dremel mill and the latest development, a laser module for laser cutting. This was on show but is not yet available for sale, it’s coming soon, I understand.

The following video was first shown on the show floor last week, and demonstrates nicely the versatility on offer ….

But it is not all about the hardware — ZMorph has also been developing proprietary software it calls Voxelizer with an emphasis again on flexibility and versatility in terms of working with a range of materials. A second video produced by the company illustrates the process …