Metal 3D printer manufacturer Velo3D has announced the launch of its latest industrial additive manufacturing system, the Sapphire XC 1MZ.

As the company’s largest 3D printer to date, the laser powder bed fusion system features a huge build volume of 600mm (dia.) x 1000mm, which is nine times larger than the original Sapphire and twice as large as the Sapphire XC.

Aimed squarely at high-performance, large part production applications, the Sapphire XC 1MZ was developed based on customer feedback from sectors such as aerospace, energy, and defense. The first batch of printers is set to be delivered to aerospace customers come late Q3 2022.

Benny Buller, Velo3D’s CEO and founder, said, “Our innovative customers have a clear understanding of how the technology can unlock new capabilities for their businesses and transform their product offerings. New systems, like the Sapphire XC and Sapphire XC 1MZ, support that transformation by significantly increasing throughput up to 400% and lowering costs by up to 75% compared to the original Sapphire.”

The Velo3D Sapphire line

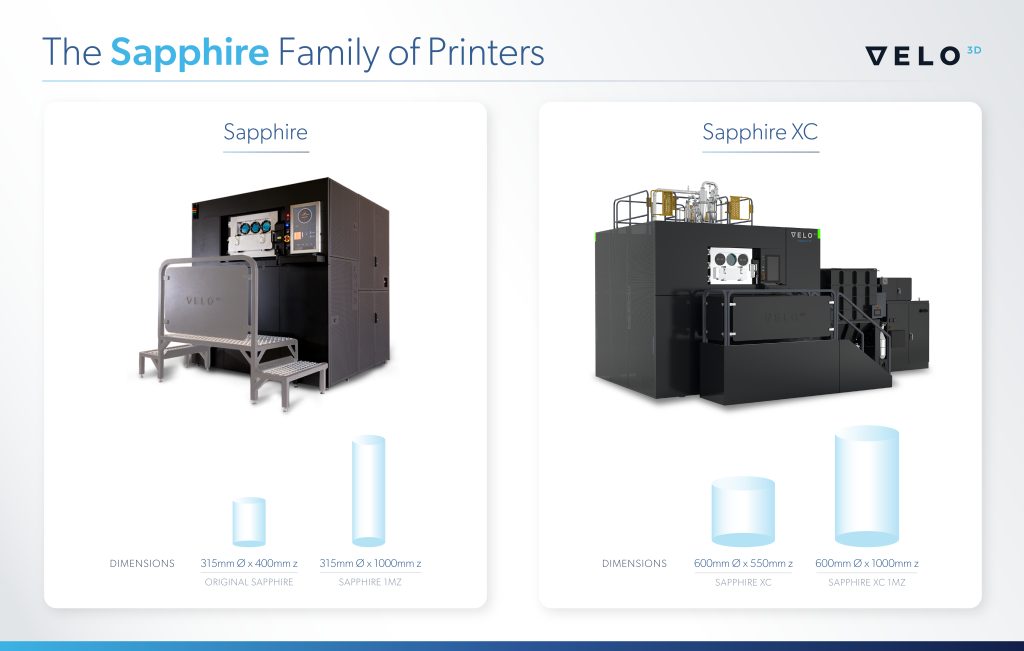

Velo3D’s Sapphire product line is now four strong. Each of the systems operates on the company’s patented SupportFree process, which is designed to enable printed overhangs and cavities without any support structures.

Launched back in 2018, the original Sapphire was the firm’s flagship machine for over two years. Equipped with a 315 x 400mm build volume, the Sapphire comes with a dual 1kW laser setup.

The upgraded Sapphire 1MZ beefed the print volume up to 315mm x 1000mm, while the more recent Sapphire XC sported 600mm x 550mm.

The Sapphire XC 1MZ

Combining the large diameter of the XC with the meter-long height of the 1MZ, Velo3D’s latest release packs eight 1kW lasers for production-scale builds at fast speeds. The machine has a faster proprietary non-contact recoater that guarantees a lack of part collision, protecting both the printed build and the recoater while slashing the downtime between layers.

With its standardized and controlled parameter sets, the XC 1MZ claims to ensure consistent geometric precision and surface finishes. The machine sports the same ‘Intelligent Fusion’ process powering the rest of Velo3D’s portfolio.

Additionally, the system is fully integrated with the company’s proprietary Flow pre-print software and Assure quality control software. The former optimizes builds with minimal supports while the latter enables real-time process and quality monitoring via in-built sensors and optics. With nearly 1000 sensors integrated into the machine, users are provided with layer-by-layer tracking of optical alignment, atmospheric validation, and powder bed health.

On the materials front, the XC 1MZ is compatible with all of Velo3D’s powder offerings. This includes Aluminum F357, GRCop-42, Hastelloy C22, Hastelloy X, Scalmalloy, Inconel 625, Inconel 718, and Ti64 Grade 5.

Technical specifications and pricing

Below are the technical specifications for Sapphire XC 1MZ. Contact Velo3D to receive a quote.

| Build volume | 600 x 1000mm |

| Machine dimensions | 8.53 x 5 x 4.75m |

| Weight | 8500kg |

| Lasers | 8 x 1kW, Class 1 |

| Throughput | Up to 400cc/hr |

| Surface finish | 5 – 15μm Sa |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sapphire XC 1MZ. Photo via Velo3D.