Vote now in the 2022 3D Printing Industry Awards.

miniFactory, a Finnish additive manufacturing solutions provider has introduced a new 3D printer to its portfolio, Ultra 2. miniFactory believes that because of the servo-driven technology, the Ultra 2 is twice as fast as its predecessor while maintaining the same miniFactory printing quality.

According to the company, Ultra 2 consists of a modern smart heated chamber that can handle temperatures up to 250°C. The heated chamber is extremely stable and allows for precise temperature control, thanks to the new triple censoring and active temperature adjustment. As a result, the printed parts are now of higher quality and precision, says miniFactory. Almost all thermoplastics are represented in the material selection, ranging from ABS, PC, and PA to PEI, PPSU, and PEEK. The emphasis on advanced functionality on the software side raises the bar for 3D printing quality assurance and reliability by becoming multi-layered and real-time, says the company.

“Brand new miniFactory Ultra 2 is packed with performance and unprecedented technical solutions that enable the effective use of 3D printing in the most demanding applications in many industries. The Ultra 2 is already in production and the first devices will be delivered in 2022,” said Olli Pihlajamäki Chief Operating Officer at miniFactory.

miniFactory’s industrial printing portfolio

MiniFactory produces heat-resistant polymers that produce the ideal results for top-tier 3D printed components. The company was founded in 2012, in Finland and serves as its home base. The company claims that its Ultra 3D is a flexible powerhouse for industrial 3D printing.

It offers the benefits of high-performance polymers like ULTEM, PEKK, PEEK, PPSU, and many more in a cutting-edge package, claims miniFactory. miniFactory’s existing portfolio includes Aarni – quality assurance technology that is necessary for reliable manufacturing says the company.

According to miniFactory, ultra polymers can be found at the top of the company’s polymer pyramid. These materials outperform traditional engineering polymers and are frequently referred to as metal replacement applications in the context of ultra polymers, where the materials’ properties shine. According to the company, 3D printing of ultra polymers is a relatively new capability made possible by the high-performance miniFactory Ultra 3D printer. The Ultra 3D printer was designed for 3D printing ultra polymers, and its 250°C-heated printing chamber ensures the highest possible quality of printed high-performance polymer parts.

Features of the Ultra 2 3D printer

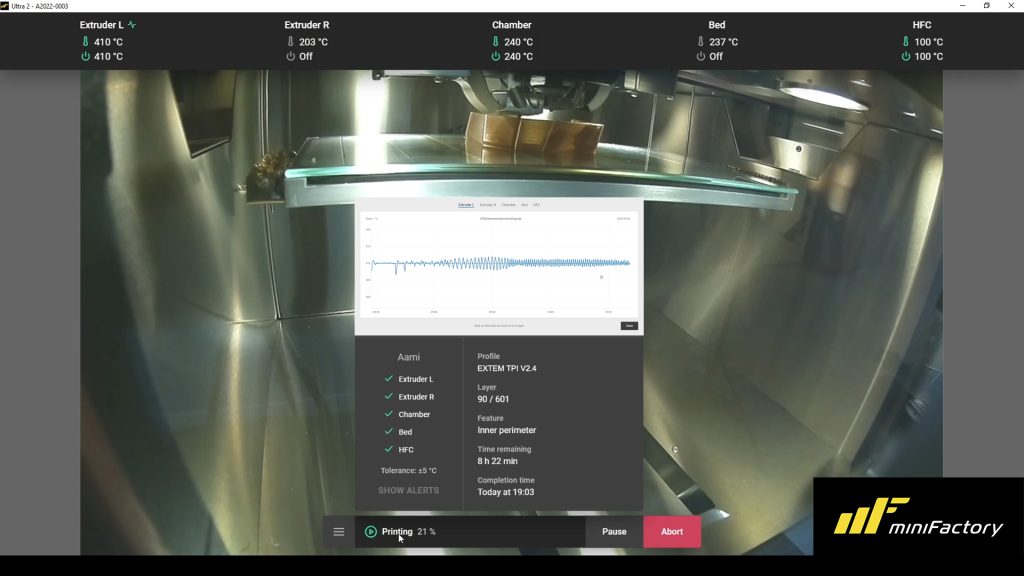

MiniFactory says that its quality control technology thoroughly examines a number of critical production steps as a whole, which is required for reliable additive manufacturing. According to miniFactory, important manufacturing steps like examining material history, operation information, layer-by-layer visualization, process history, manufacturing reports, and finally, a quality report of the produced parts are compiled together in this technology.

By using the remote-control system with live feed, a single user can manage the entire production ecosystem. All manufacturing-related data is always available, and multiple devices can be managed simultaneously.

miniFactory claims that planning and managing the manufacturing process is also made more effective and simple. The main highlight of the quality control technology is real-time production supervision. It is a distinctive feature that “takes production monitoring to a whole new level,” says the company.

Following the Ultra 2 launch, miniFactory plans to display some of its prototypes at booth E22 in Hall 12.1-F29 at Formnext, which will be held from 15-18 November, 2022 in Frankfurt, Germany.

Technical specifications and pricing

Below are the technical specifications for the miniFactory Ultra 2 metal 3D printer. The machine is available to order now, with prospective customers seeking pricing information able to request a quote from miniFactory directly.

Chamber temperature: 250°C

Platform temperature: 250°C

Extruder temperature: 480°C

Mechanics: AC-Servo Motors & Ball Screws Class C5

Repeatability: 0,025MM/400MM

Extruders: 2, Separable Extruders

Build volume: 330MM x 180MM x 180MM

Materials: TPI, PEI, PEKK, PEEK, PPSU, PPS, PVDF, PA, PC, ABS + MORE + Wide range of GF/CF composites and ESD Polymers

Build platform: Internal vacuum system

Leveling: Fully automatic calibration

UI: 10” touch screen / MF2 UI

Safety: Activated carbon filtering

Filament diameter: 1,75MM

Cooling: Liquid cooling & air cooling

Sensoring: Jam & Runout Sensors

Integrated features: Aarni – Quality Assurance Technology Remote Control + On-board camera Material drying chamber Smart maintenance intervals Full system statistics Integrated annealing system

Slicing software: Simplify 3D, Cura

Certification: CE, UKCA

Device measurements: 100 x 80 x 190CM – 320KG

Power requirement: 400V/16A 3-Phase

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows miniFactory ultra 2 3D printer product supervision. Image via miniFactory.