The Critical Imports and Supply Chain strategy published this month by the Department for Business and Trade (DBT) is the UK’s first overarching initiative designed to secure access to critical goods, and will see the government set up a Critical Imports Council.

3D Printing Industry spoke with the DBT to understand how 3D printing is used to mitigate supply chain risks. “Technological innovations, such as those brought in by the 3D printing industry, have the potential to transform supply chains and how they operate, in ways that will build a stronger, more resilient economy,” said a DBT spokesperson.

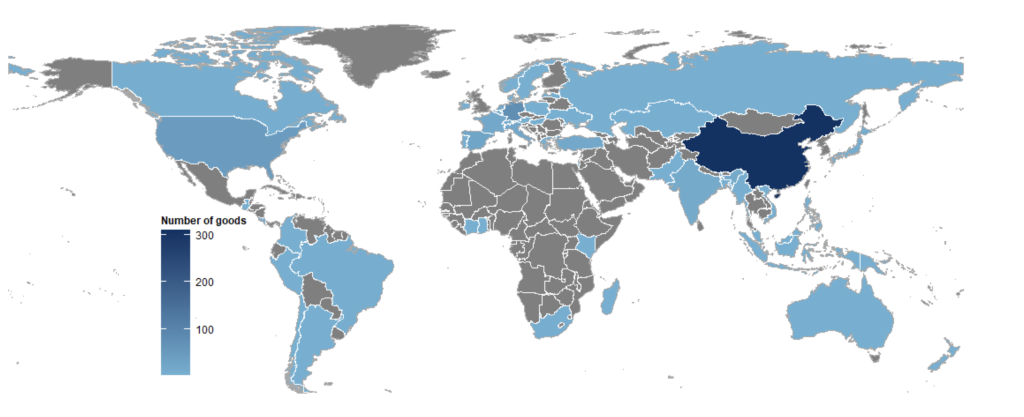

The policy paper follows the emergence of threats to imports, including the COVID-19 pandemic, ongoing conflict in Ukraine, attacks on shipping in the Red Sea and Gulf of Aden, and increased tension in the Taiwan Strait and South China Sea. Disruptions associated with climate change, trade protectionism, and other unforeseen circumstances also motivated the strategy.

Building on prior inter-governmental work on critical supply chains, the new strategy outlines five key priorities for building supply chain resilience for importing businesses. It seeks to secure the country’s global supply of critical goods such as medicines, minerals, and semiconductors.

These include making the UK a center of excellence for supply chain analysis and risk assessment, removing import barriers, bolstering the country’s response to supply chain shocks, adapting to long-term trends, and promoting collaboration between government, business, and academia.

As part of these priorities, the DBT points to the development and increased adoption of 3D printing as being key to onshoring the manufacture of critical goods. “Through the Critical Imports and Supply Chains Strategy we are exploring opportunities to develop domestic capability to produce critical goods and reduce our reliance on concentrated imports, where there is economic rationale to do so,” said the DBT spokesperson.

A new strategy to secure global supply chains

The Critical Imports Council will work with businesses to improve analysis of potential supply chain challenges, identifying risks to the most sensitive imports and creating action plans.

A new program of work will also be set up to “identify, review and where feasible remove import barriers.” This will include the creation of a new “critical import barrier reporting mechanism,” which will enable businesses to inform government action on alleviating import challenges.

The supply chain strategy builds on the UK Government’s previous work to expand the role of additive manufacturing within the UK’s industrial base.

The Department for Business and Trade’s Advanced Manufacturing Plan, published in November 2023, highlighted the importance of growing additive manufacturing as part of its Industry 4.0 goals. Here, the Government aims to empower UK businesses to streamline and automate their manufacturing processes through technologies such as 3D printing and artificial intelligence (AI).

The Department first committed to the Industry 4.0 initiative in its 2017 Made Smarter Review. This review outlined that additive manufacturing is actively disrupting traditional manufacturing processes within UK-based industries such as aerospace, maritime and automotive, and defense.

More recently, Dame Angela McClean authored a Pro-Innovation Regulation of Technologies Review. This highlighted the need to remove remaining constraints on the use of additive manufacturing by UK-based manufacturers.

The recommendations included agreeing a national approach and regulatory framework regarding the use of additive manufacturing, which keeps pace with further technological advances. Specifically, the review noted that newly defined standards for the additive manufacturing process could lower the cost for businesses, and accelerate the pace of production.

McClean also recommended that the UK should directly engage with the International Organization for Standardization (ISO) and other international regulatory bodies to influence global 3D printing standards. The UK Government has subsequently accepted these recommendations, acknowledging the need for cross-sector engagement in additive manufacturing.

Government-run 3D printing bodies such as the High Value Manufacturing Catapult and the Manufacturing Technology Centre, including the National Centre for Additive Manufacturing (NCAM), will reportedly play a key role in facilitating this engagement. UK manufacturers can leverage NCAM capabilities for prototyping or initial production runs.

Strengthening supply chains with additive manufacturing

The Department for Business and Trade is not the only UK Government agency to alleviate supply chain disruptions through additive manufacturing. In December 2023, UK-based 3D printing SME Additive Manufacturing Solutions Ltd. (AMS) announced a collaboration with the UK Ministry of Defence’s (MoD) Defence Equipment Sales Authority (DESA).

This partnership sees AMS research the technical feasibility of recovering critical materials from surplus Defence Assets. In this collaboration, AMS will initially work with an unnamed MoD supplier to deliver demonstrative geometry using recycled 3D printing materials. AMS will then focus on material industrialization and qualification. This is the first stage of a long-term project that the MoD hopes will enhance its knowledge and control over current and future material sourcing strategies.

This follows the 2022 launch of the MoD “Project TAMPA,” which seeks to establish a secure network of suppliers capable of 3D printing military-grade parts on-demand. With an initial budget of £5 million, this project sees contracted suppliers 3D print a variety of parts to drive down military equipment and weaponry lead times, and improve the availability of difficult-to-source obsolete components.

Away from the UK, North Carolina-based titanium developer IperionX secured development permits for the Titan Project in Tennessee. Titan plays a key role in securing material supply chains for titanium and rare earths needed for US defense, electric vehicle, and renewable energy applications.

This project is reportedly key to IprionX’s plans to reshore a sustainable supply chain for titanium within the US. The company is working to close the loop on this supply chain by developing titanium recycling capabilities.

More information about the Critical Imports and Supply Chain strategy is available online.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Department for Business and Trade plaque. Photo via the Department for Business and Trade.