3D printer OEM Stratasys and Ricoh, a multinational electronics firm headquartered in Japan, are working together to provide on-demand 3D printed anatomic models for clinical settings.

Stratasys says by utilizing 3D printing technology, realistic anatomic models can be created to visualize a patient’s anatomy. With Stratasys’ Patient-Specific 3D Solutions, medical professionals can easily plan and rehearse intricate surgeries, while also enhancing communication between the care team, the patient, and their family. This novel solution combines Stratasys’ 3D printing expertise, Axial3D‘s Segmentation-as-a-Service solution, and Ricoh’s precision additive manufacturing services, to create a comprehensive offering. The partnership between Ricoh 3D for Healthcare and Stratasys continues to evolve, expanding access to 3D printed medical models and advancing the healthcare industry.

“We are providing an opportunity for healthcare providers to access state-of-the-art, precision additive manufacturing without absorbing the overhead costs,” Gary Turner, managing director of Additive Manufacturing, Ricoh USA. “Offering this solution means democratized, wider access to patient-specific 3D printed models that can improve outcomes and the patient experience, while enhancing physician education and training.”

Innovative service brings personalized 3D printed models to surgical planning

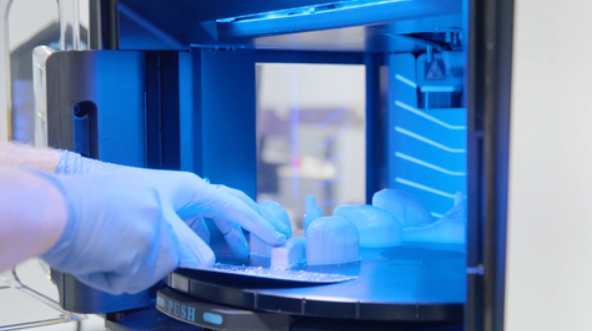

Stratasys’ Digital Anatomy technology produces models that closely resemble the biomechanical properties of real bone and tissue, benefitting both patients and care teams in surgical planning. However, due to the need for upfront capital investments and 3D printing technical expertise, its implementation has been limited in some healthcare facilities. This new service aims to overcome these challenges by providing a solution that is easily accessible, which will ultimately enhance clinical outcomes improving productivity, resulting in substantial cost savings.

With the introduction of this new service, clinicians and patients will have greater access to patient-specific 3D printed models for surgical planning, diagnosis, and education. The use of these models allows clinicians to showcase treatment options to patients and surgical staff. Through this partnership, clients can securely upload medical files to a cloud-based service, which utilizes Axial3D’s AI-powered software to convert medical scans into 3D printable files. Subsequently, the files are 3D printed on Stratasys 3D printers at Ricoh’s ISO 13485-certified facility and shipped directly to the healthcare facility. This streamlines the process, reducing the time it takes from weeks to days, without necessitating on-site 3D printing equipment or additive manufacturing know-how.

“With the advancement in imaging techniques and 3D printing technology, we are seeing an increased demand for personalized solutions,” said Ben Klein, General Manager of Patient-Specific Solutions for Stratasys. “We offer a simplified and scalable, comprehensive solution that increases access to patient-specific 3D printed models in a fraction of time to help deliver highly personalized treatment and care.”

3D printed medical models offer realistic and cost-effective alternatives

A proof-of-concept 3D printed spinal surgical model was created by a group of researchers from the Mayo Clinic, the Georgia Institute of Technology, and the Medical University of South Carolina. The study aimed to raise awareness of the lack of surgical training alternatives to conventional methods that can be inconvenient, inaccessible, and incompatible with intraoperative neuromonitoring (IONM) systems. To offer a low-cost alternative, the team developed the lateral access training model (LATM), which showcased 3D printed lumbar vertebrae verified for anatomical accuracy.

Paris-based medical technology company Biomodex launched a 3D printed heart model for the transseptal puncture procedure. The model was designed to replicate the geometry, feel, and haptic feedback of actual heart tissue, allowing electrophysiologists and cardiologists to practice in a more lifelike environment. The model was also compatible with ultrasound. Consequently, the model could be used in ultrasound-guided practice runs, similar to how the actual procedure is carried out. Dr. Juan Granada, President of the Cardiovascular Research Foundation, said, “Adoption of emerging structural heart technologies require the operators to receive more specialized training to further industry adoption. Biomodex’s latest solution offers an innovative alternative over traditional training methods because it enables physicians to gain experience by working on humanized models and using clinically adopted imaging tools in a real cath-lab environment.”

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows anatomic 3D printed models allow medical staff to practice and plan for surgeries. Image via Stratasys.