Swiss hearing solutions technology company Sonova started using 3D printers for custom hearing aids at the start of the millennium.

Expanding on this additive expertise, Sonova’s hearing aid range has expanded to include the Virto B-Titanium – the company’s first ever titanium device made using additive manufacturing.

Animation of the powder based 3D printing process used to make the Virto B-Titanium hearing aid. Clip via Phonak on YouTube

Custom-made hearing aids

Each year, Sonova and its subsidiary brand Phonak produce hundreds of thousands of custom-made hearing aids for patients around the globe.

To start, an impression of a patient’s ear canal is taken by hand using silicone. This mold is 3D scanned, then turned into a digital model using software from partners at Materialise.

The custom models are then 3D printed in acrylic using a light-powered vat polymerization technique.

Improving upon the strength and fit of these model, Phonak’s new Virto B-Titanium device is made using the powder bed fusion method of metal 3D printing.

Smaller, stronger, more resistant

The Vitro B’s titanium casing is 15 times stronger than the shell of an average acrylic device, making it more hardwearing and resistant to water. The device is also 26% smaller than the average Phonak product, making it no bigger than a fingertip.

Scott Witt, director of product management at Phonak, calls the Virto B-Titanium “the most discrete hearing aid ever produced” by the company. This matches a majority demand from patients for an “invisible device” that fits well within the ear canal but also provides performance.

What’s next for Sonova?

Patrizia Richner is a digital manufacturing engineer for the Sonova Group in Switzerland. This week at the International Additive Manufacturing and 3D printing conference in Nottingham Richer will be speaking on the advanced applications of the technology within the company’s latest projects.

Robin Wilson, lead technologist for high value manufacturing at Innovate UK, also tipped Sonova in his guest article on the Future of 3D Printing.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

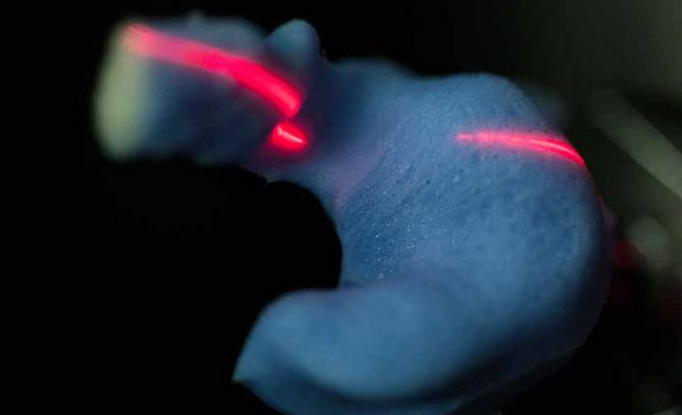

Featured image shows: A Virto B-Titanium hearing aid. Image via Phonak