Metal 3D printing company Seurat Technologies has raised $99 million in a Series C funding round. The Massachusetts-based company will use this funding to “decarbonize manufacturing” through the deployment of localized metal 3D printing factories leveraging the company’s ‘Area Printing’ technology.

Seurat plans to deploy its 3D printing factories at or near customer sites around the world. This will reportedly allow parts to be 3D printed closer to where they are needed, reshoring supply chains and reducing carbon emissions from transportation and global logistics.

“This new funding will enable Seurat to unlock our next phase of growth, deploy our new machines and scale our factory capacity to meet current demands,” explained James DeMuth, co-founder and CEO of Seurat.

The funding round was led by NVentures, the venture capital arm of GPU manufacturer NVIDIA, and Capricorn Investment Group’s Technology Impact Fund which is focused on climate solutions. New investors Honda Motor and Cubit Capital participated in the funding round, which also drew support from previous investors such as True Ventures, SIP Global Partners, Porsche Automobil Holding SE, Denso Global, General Motors Ventures, Maniv Mobility LP, and Xerox Ventures.

“Seurat’s potential to disrupt and decarbonize the traditional metal parts manufacturing industry is tremendous,” commented Ion Yadigaroglu, Partner at Capricorn. “We have been impressed from the early days of the company by James and his team’s technical expertise and acumen to build a highly scalable business, with applicability across numerous industries. We are excited to participate in this round of funding, which will enable the company to ramp up production capabilities at greater scale and ultimately grow its client base.”

“Seurat has an innovative concept and technologies for metal additive manufacturing, and Honda has high expectations for their future potential,” added Manabu Ozawa, Managing Executive Officer of Honda Motor Co. “The metal additive manufacturing technology will enable the enhancement of the value of products through innovative design, and as Honda strives to create the joy and freedom of mobility, we envision that this technology will be necessary for us.”

Seurat’s mission to decarbonize manufacturing

Seurat outlines manufacturing as one of the largest contributors to greenhouse gas emissions. The company claims that current manufacturing processes take too long, stifle innovation, contribute to climate change, stretch supply chains, and offshore jobs.

Indeed, manufacturing is currently responsible for 31% of greenhouse gas emissions in the US. To tackle this, the Biden Administration recently announced a green manufacturing investment, committing $6 billion to cut industrial emissions.

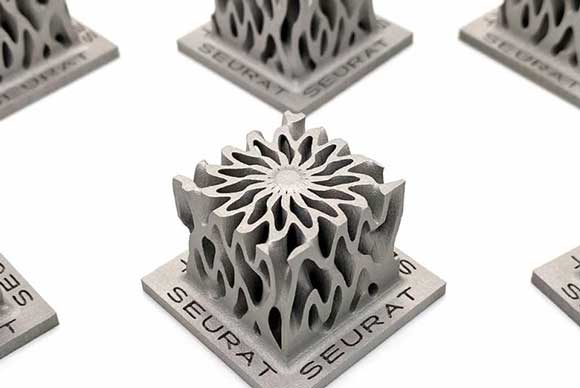

Seurat’s proprietary Area Printing technology seeks to meet these sustainable manufacturing demands. First honed at Lawrence Livermore National Laboratory, the Area Printing process uses a laser containing over 2.3 million pixels to ‘micro-weld’ metal powder into thin layers on a 3D print bed.

Reportedly powered by 100% green energy, Area Printing technology is said to allow for high-precision, high-volume, decarbonized manufacturing. According to Seurat, this technology has the potential to directly mitigate up to 100 million tons of CO2 by 2030. By organizing this technology onto “print factories,” Seurat hopes to scale its offering to provide sustainable, high-volume manufacturing.

“Our mission is to create a green manufacturing industry,” explained DeMuth. “With our additive manufacturing technology, our print factories will provide our customers with clean manufacturing that can compete with the volumes, quality, and price points of traditional manufacturing.”

Seurat will deploy its first pilot factory in the Greater Boston area, which will reportedly have the capacity to 3D print more than 25 tons of metal parts annually. Additionally, the company has committed to develop 59 tons of 3D printed metal components for energy technology firm Siemens Energy over a period of six years. These parts will meet the necessary material qualification requirements.

In all, Seurat has letters of intent (LOIs) from six customers, totalling 4,000 tons of material and over $750 million in projected revenue over the next several years.

Recent investment in 3D Printing

Worldwide, a 53 percent decline in venture capital funding year on year was seen during the first quarter of 2023. However, a number of 3D printing companies have been successful in attracting external investment.

It was recently announced that London-based 3D printing software company Ai Build has raised $8.5 million in a Series A funding round. This investment will be used to accelerate Ai Build’s product roadmap and provide more industrial 3D printing customers with its artificial intelligence (AI) driven 3D printing software. The company also plans to use this investment to expand into North America with a new US-based subsidiary and continue its growth throughout Europe.

Elsewhere, US-based titanium developer IperionX recently received a LOI from Export-Import Bank of the United States (EXIM Bank) for potential equipment finance of US$11.5 million. This financing is intended to support the development of IperionX’s Titanium Production Facility in Virgina, with the aim of reshoring US titanium supply chains.

“Titanium for the U.S. manufacturing sector is currently sourced over long distances from foreign nations. We are pleased to receive the letter of interest for the provisional sum of $11.5 million in equipment finance from US EXIM that will assist IperionX to re-shore a lower-cost, more sustainable and fully integrated U.S. titanium supply chain,” commented Anastasios (Taso) Arima, IperionX CEO.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a Seurat Technologies metal 3D printed part. Image via Seurat Technologies.