When a start-up is launching a new 3D printing product on the global market, I generally suggest they remember two things above all: having a great product with unique features and communicating it adequately. Roboze, a young startup from Bari, the main city in Southern Italy’s Apulia region, has been doing both, as I was able to confirm when I visited their factory last week.

After numerous email exchanges with marketing director Ilaria Gucciardini, I combined the visit with a talk I was to give at the Bari Creativity Day series of conferences, where I presented my new book on 3D printing, in Italian. 3DPI has already reported that the Roboze One 3D printer offers a particular technology which guarantees higher accuracy and repeatability. That, however, is a claim made by several companies. I wanted to see it for myself.

“We patented a mechatronic moving system and we simply did away with all problems caused by the belts, such as dilation, contraction… a belt never does the same exact moment twice in a row,” Alessio Lorusso, the company’s 24-year-old founder, told me as he took us around the assembly plant. Incidentally, Roboze is located next to the conservatory, so the entire time we could hear lyrical singers and instruments been played in the background. The “music” theme is a recurring one at Roboze, since Ilaria is also a talented singer, albeit of a more modern “house music” variety that goes by the name of Lil’ Brash. This below, on the other hand, is the kind of music the machine makes.

Alessio is the son of a local entrepreneur who built a manufacturing company specializing in mechanical theft prevention devices for cars. Working with CNC mills and other mechanical devices, he developed a passion for robotics at a young age and purchased his first RepRap system in 2008. He assembled it and decided that it could be done better, so he began designing the Roboze One. In the beginning, he was looked upon skeptically by the “older” members of the company. Now that the machine is ready, on the other hand, everyone had understood its potential.

“We did not expect such enthusiasm from the very beginning,” Alessio confessed. “We launched it two months ago and have already sold the entire first batch of machines, receiving requests both locally and from abroad. We are already in contact with a Dutch distributor and are looking to expand operations into the UK and elsewhere. We are working full time just trying to keep up with demand.”

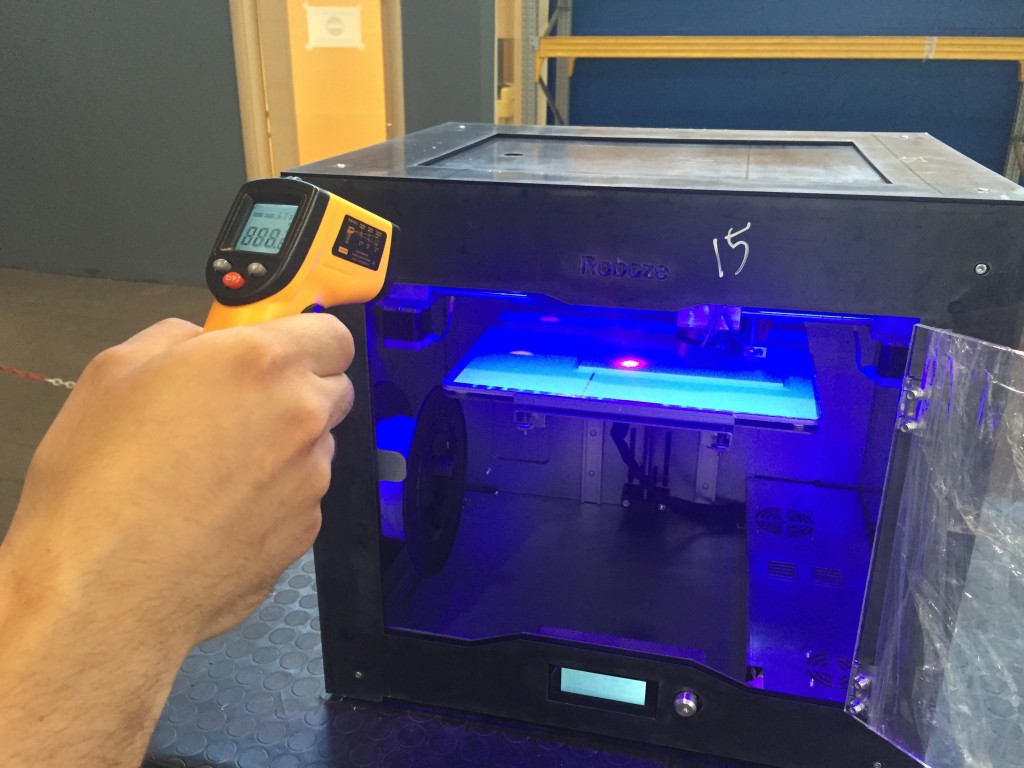

Alessio’s vision has been, from the very beginning, to target the many SMEs in Italy and abroad. To do this, he developed a technology which integrates a Core XY architecture with a beltless, full-metal system that moves the extruder. This enables the machine to repeatedly guarantee 50 micron accuracy and 50 micron layer resolution while printing at 90 mm/s (with 250 mm/s as stated maximum speed). It also integrates a 280 x 220 x 220 mm enclosed print volume and a heated plate which uses a particular technology to guarantee an even temperature throughout. Roboze guarantees performance on four proprietary materials, including one flexible feedstock, but the machine also supports all other filaments, with extrusion temperatures up to 300°C.

“This means that, if I make a CAD design with certain measurements, it will have those same exact dimensions when I build it as well, with a maximum discrepancy of 50 micron. The movement is immediately transmitted to the extruder; there is no time loss with the belt.” Apart from the front plexiglass cover, there is not a single plastic component in the entire machine. “It is entirely built in stainless steel, iron, and aluminum and we produce 60% of the components in-house,” Alessio said.

This level of accuracy, combined with internal development of advanced materials, has opened up the dental applications market to the Roboze One. It is already being used to produce dental models from intraoral 3D scans, at costs that are significantly lower compared to both traditional technologies and high-end, resin-based 3D printers. These are then used to create sets of clear plastic, custom braces, but the possible applications go much deeper. “We are currently developing a new, even more precise machine and a new material approved for internal use, together with Italy’s CNR, the National Research Center,” Alessio revealed. “This means that we will be able to use FFF technology to effectively produce both surgical guides and temporary caps and dental prosthetics.”

Seeing the machine and what it is capable of up close gave me a clearer idea of what it can do. Alessio shares the enthusiasm for the possibilities offered by 3D printing. Even though he has already won his bet on the Roboze One, he is constantly looking ahead to new technologies and applications. That is why the Roboze logo is a stylized cocoon that has just turned into a butterfly, a symbol for constant change and evolution, striving for mechanical precision on the wings of an opera aria.