Engineers from Purdue University have begun working on a method of 3D printing concrete wind turbine parts for offshore use. According to the U.S. Department of Energy, harnessing wind energy off the coast of the U.S. could generate more than double the total electricity output of all the country’s electric power plants. The main issue to date has been the costs associated with this, as building and shipping steel wind turbine anchors at least 30 miles from the coastline has proven to be costly. The Purdue research aims to eventually 3D print these same steel anchors out of concrete, which is less expensive and would allow parts to simply float to an offshore site.

Pablo Zavattieri, a Civil Engineering Professor at Purdue, explains: “One of the current materials used to manufacture anchors for floating wind turbines is steel. However, finished steel structures are much more expensive than concrete.”

3D printing concrete structures

The researchers could have gone down the route of traditionally manufacturing concrete parts for the turbines. However, this would have required a mold to produce the structure and geometry they wanted, which incurs additional costs and limits design freedom. With 3D concrete printing, the mold is omitted from the process entirely.

The current project is actually a development of the team’s prior research on 3D printing bioinspired designs (like arthropod shells) with cement-based materials. The researchers are now working to integrate a robot arm with a concrete pump to 3D print large parts in a process that is effectively large-scale FDM. To scale-up their already established method of 3D printing, the team had to first formulate a special feedstock mixture of cement, sand, aggregates, and chemical admixtures to provide shape stability for the concrete. The next step is to 3D print the new concrete mixture at a large-scale and investigate how gravity affects the durability and integrity of larger concrete structures (such as wind turbines).

Mohamadreza Moini, a Ph.D. student at Purdue, explains: “The idea we have for this project is to scale up some of the bioinspired design concepts we have proven on a smaller scale with the 3D printing of cement paste and to examine them on a larger scale.”

Jan Olek, a Purdue professor, adds: “Printing geometric patterns within the structure and being able to arrange the filaments through or playing around with distribution of the steel are both possibilities we have considered for optimizing and reinforcing the structures.”

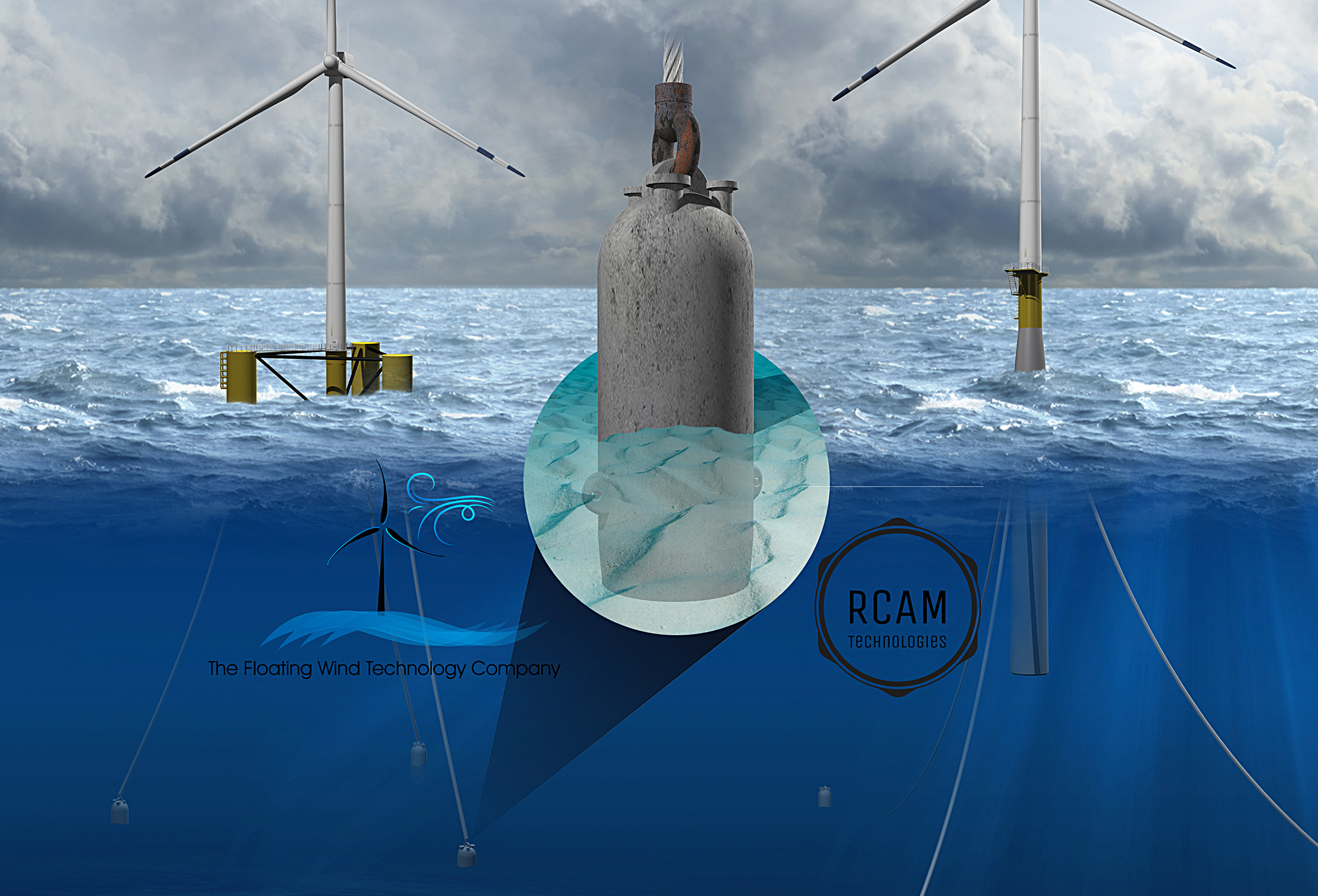

The Purdue researchers are working in collaboration with RCAM Technologies, a startup focused on developing concrete AM technology for wind energy applications. The project is funded by the National Science Foundation INTERN program.

A number of institutions and organizations around the world are looking to develop concrete 3D printing for a range of applications. Earlier this year, Twente AM unveiled its latest large-scale concrete 3D printer at the 40th annual Big 5 International Building & Construction Show in Dubai. The machine has an impressive printing footprint of 391m³. Elsewhere, the U.S. Marine Corps conducted its first 3D concrete printing operation at the Construction Engineering Research Laboratory (CERL) in Champaign, Illinois.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows proposal for the 3D printed concrete wind turbine anchors. Image via RCAM Technologies.