Canadian engineering and additive manufacturing service provider Precision ADM has been granted two new Quality Management System (QMS) certifications.

Under the new standards, the company has been assured for consistent production, and is better positioned to provide services to the aerospace industry.

Martin Petrak, CEO of Precision ADM, which is based in Winnipeg, Manitoba, comments, “Our team continues to prove to be industry leaders. In 2017 we were the first Canadian metal AM service provider to achieve ISO 13485 certification for medical applications, and now in 2018 we are again the first to hold both certifications for medical and aerospace,”

“We are proud of our team’s accomplishment in reaching this significant milestone and are excited to work under these quality systems with our aerospace and defense customers.”

Precision ADM powered by EOS DMLS

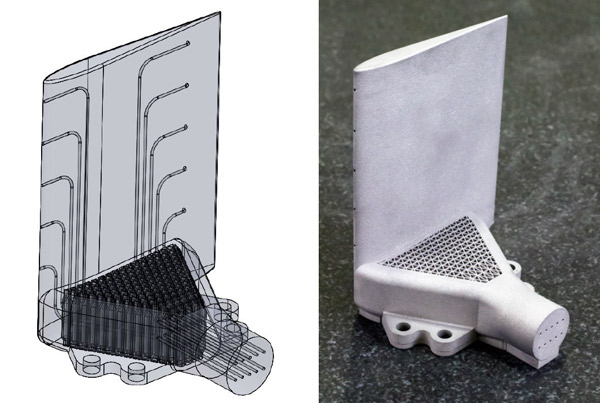

Founded in 2015, Precision ADM offers engineering, design, 3D printing, post processing, machining and metallurgical service to a global pool of industrial clients.

Its metal additive manufacturing expertise lies in DMLS, a service which the company believes is the largest of its kind in Canada. Precision ADM DMLS is delivered by a fleet of metal 3D printers from EOS.

Earlier this year, working with EOS consultancy business Additive Minds, Precision ADM created a “Validation Master Plan” for this technology.

Explaining the document at the time of release, Petrak said, “[…] we have invested in designing and completing a robust end-to-end validation of our metal additive process, so that we can assure our customers of reliable, repeatable manufacturing results.”

Additive manufacturing demand in aerospace

The two new QMS certifications received by Precision ADM are AS9100 Rev D and ISO 9001:2015, which are inextricably linked to one another.

ISO 9001:2015, from the International Organization for Standardization (ISO), specifies the requirement for a QMS that ensures repeatability of products, applied to a business that “aims to enhance customer satisfaction through the effective application of the system.”

Amended by the International Aerospace Quality Group (IAQG) AS9100 Rev D is an extension of ISO 9001:2015, modified for specific aeronautical use. Its full title is: “Quality Systems-Aerospace-Model for Quality Assurance in Design, Development, Production, Installation and Servicing.”

For Precision ADM this, according to Dale Kellington, Director of Quality, gives “….aerospace and defense customers the confidence they need that our manufacturing output will meet their stringent requirements.”

The specifically includes the additive manufacturing of aerspace-grade components, as Ian Klassen, Director of Aerospace Sales at Precision ADM, says “The additive manufacturing experience and expertise that of our team of engineers possess give us the ability to solve the many complex issues facing our aerospace clients today.”

Klassen concludes:

“The demand for additively manufactured parts is disrupting existing supply chains and we are excited to part of the advanced manufacturing revolution.”

Think Precision ADM, EOS or Additive Minds have earned a 3D Printing Industry Award? Nominate these companies and more in the 2019 3D Printing Industry Awards.

Keep up with additive manufacturing standards – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Post a vacancy or find your next career move on 3D Printing Jobs.

Featured image shows a fleet of EOS M 290 machines. Photo via Precision ADM