Time is running out! Nominate now for the 3D Printing Industry Awards 2023.

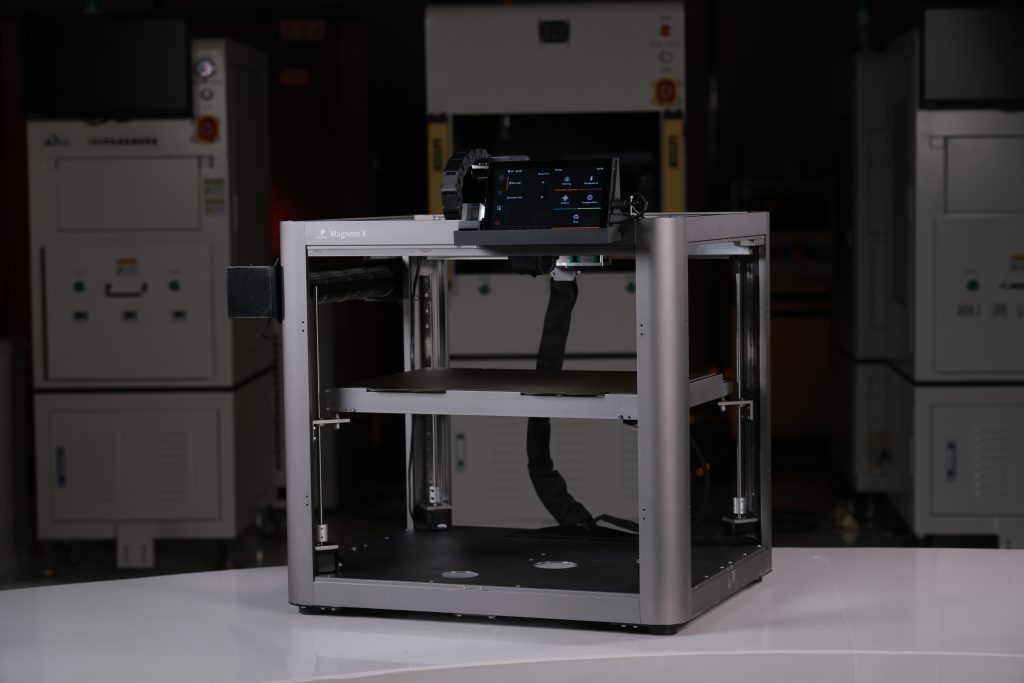

Hong Kong-based 3D printer manufacturer Peopoly has launched the Magneto X, the world’s first MagLev-based desktop FFF 3D printer.

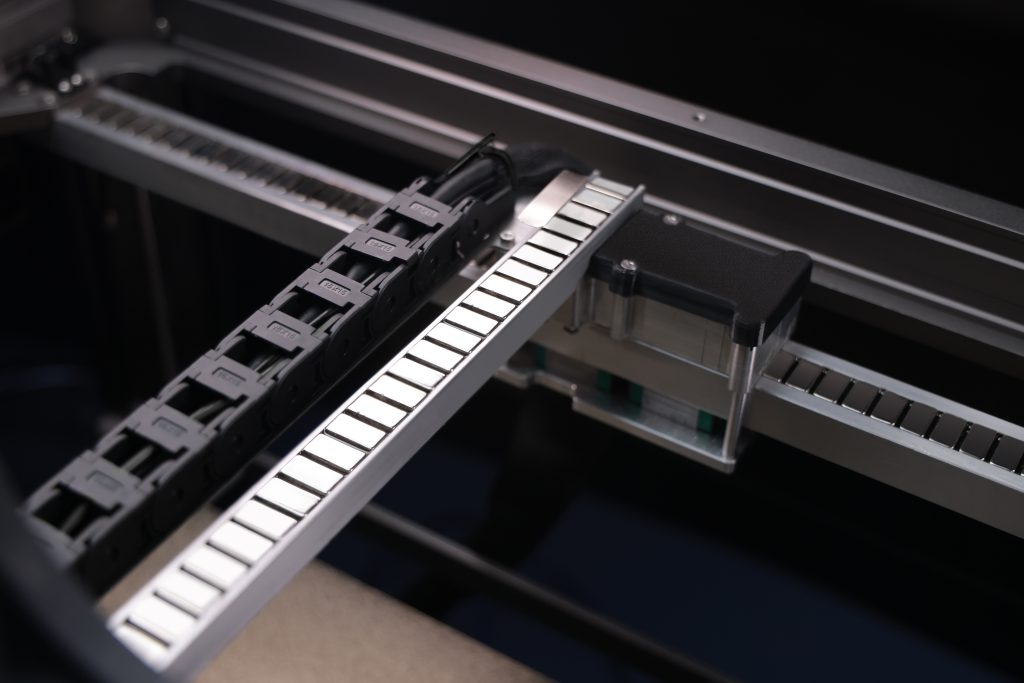

Doing away with belts and pulleys, Peopoly’s new 3D printer employs a proprietary MagXY magnetic linear motor system for the X and Y axes. According to Peopoly, this magnet-driven system enables high-performance 3D printing, combining fast 3D print speeds with high levels of precision and reliability.

MagLev (short for magnetic levitation) technology is usually reserved for high-speed train and low-noise aerospace applications. Earlier this year, Boston-based ultra-quiet vertical flight system developer MagLev Aero partnered with 3D printing OEM GE Additive’s AddWorks consultancy team to develop the company’s proprietary MagLev HyperDrive aero propulsion platform. This magnet-powered platform is designed for use in electric vertical take-off and landing (eVTOL) aircraft.

Peopoly’s new MagLev 3D printer is available to pre-order now via the company’s official website, with the Magneto X set to be showcased for the first time at the East Coast RepRap Festival (ERRF) between September 30 and October 1.

Initial availability is open to customers in the United States, Canada, the United Kingdom, the European Union, and Australia. The first units will begin shipping in mid-November.

Key features of the Magneto X

Key to the Magneto X’s functionality is Peopoly’s proprietary MagXY magnetic levitation linear motor system, which controls the 3D printer’s X and Y axes. Employing electromagnet technology instead of traditional belts and pulleys, this motion system is said to eliminate artifacts, such as ringing and vertical fine artifacts (VCA), that are common with FFF 3D printers.

Additionally, the MagXY system remains cool during 3D printing, enabling high accuracy and repeatability of 3 microns. This is achieved through a true closed-loop system with position feedback. According to Peopoly, the motor can self-correct lost steps and offers extensive optimization data.

3D printer’s reliant on stepper motors can often suffer from reduced precision under heavy loads, a limitation not shared by the new Magneto X. The Magneto X’s linear motor system is also said to offer streamlined motion compared to 3D printers that use stepper motors and belts.

Moreover, unlike traditional belt-driven 3D printers, the Magneto X does not require tension adjustments or extruder replacements. Lower rail friction is also said to extend the system’s useful lifespan, limiting the need for frequent calibrations, lowering downtime and offering long-term cost savings. According to Peopoly, this longevity makes the MagLev 3D printer ideal for high-production applications such as home businesses and 3D print farms.

The Magneto X’s low-friction linear motor also allows for fast 3D print speeds. In fact, this new FFF 3D printer can achieve 3D print speeds of up to 1200mm/s, with a maximum acceleration speed of 22,000mm2/s.

High-speed 3D printing can often result in sacrifices relating to quality and reliability. However, Peopoly claims that the Magneto X overcomes this problem through the extrusion system’s ability to extrude material quickly and consistently.

The 3D printer’s Lancer extruder offers an extrusion force of 90 Newtons and a 30mm/s filament speed. What’s more, it can achieve a maximum flow rate of up to 60mm3/s, thanks to a variable-length melt zone. Additionally, the Magneto X employs a standard E3D V6 volcano-style nozzle, which is easy to replace and offers broad filament compatibility, Peopoly claims.

The Lancer extruder also incorporates a load sensor and a filament runout sensor. Before each 3D print, the Magneto X’s four independently driven Z-axis rods are calibrated by the load sensor, leveling the build plate. The extruder then performs a 48-point mesh measurement on the build plate, which can quickly heat up to 130℃, capturing detailed data for calibration. This mesh data is used to set the Z-offset, ensuring precise automatic bed leveling. What’s more, the filament sensor constantly monitors material levels, preventing 3D print failures caused by material depletion.

With a 400 x 300 x 300 mm build volume, the Magneto X is well suited to 3D printing parts for a range of applications. Additionally, Peopoly’s new 3D printer is equipped with a 300℃ hot end and includes 0.4 mm copper and hardened steel nozzles. As such, the Magneto X is compatible with a variety of materials such as PLA, PETG, ABS, ASA, and Nylon-Carbon FIber.

The Magneto X features a 7” IPS touchscreen user interface and runs Klipper firmware. This firmware is said to include a transparent code base, with the 3D printer not storing or sending data in the cloud. Peopoloy claims that this ensures operability alongside full security and IP protection. The Magneto X also supports Orca Slicer, PrusaSlicer, and Cura, and offers multiple connection options including WiFi, Ethernet, and an SD card offline mode. A 1080P HiDef camera is also included, enabling real-time 3D print monitoring and time-lapse recording.

Additional Magneto X features include optional side enclosure panels and a top cover, 1000W AC power supply, and a PEI magnetic surface for quick and easy part removal. Moreover, consistent cooling is ensured during fast 3D prints by a jetstream-style side fan.

Technical specification and pricing

Available to pre-order now, prices for the new Magneto X start at $1399 USD. However, this is set to rise to a standard retail price of $1999 USD once the pre-order period ends.

Magneto X orders are set to be fulfilled as fully assembled units with Peopoly noting that, due to shipping constraints, users will be required to mount the heat bed themselves. This process takes approximately three minutes, according to Peopoly.

| 3D Print Technology | Fused Filament Fabrication (FFF) |

| Motion System | MagXY |

| Movement Precision | 3µ |

| Error Correction | Full Closed Loop |

| Maximum 3D Print Speed | 800mm/s at 0.2mm layer height 1200mm/s at 0.1mm layer height |

| Maximum Travel Speed | 1500mm/s |

| Maximum Acceleration | 22000mm/s2 |

| 3D Print Volume | 400 x 300 x 300 mm |

| Build Platform | 400 x 300 mm |

| 3D Printer Dimensions | 55 x 61 x 70 cm |

| Leveling | 48 Mesh Points Auto-Leveling via Load Cell Sensor |

| Extruder Name | Lancer |

| Maximum Hot End Temperature | 300℃ |

| Maximum Extrusion Force | 90 Newtons |

| Maximum Filament Speed | 30mm/s |

| Nozzle Material | Copper, Hardened Steel |

| Supported Materials | PLA, PETG, ABS, ASA, PA6, PA12, PA-CF, PC-GF, TPU, and more |

| Slicer Compatibility | Orca Slicer, PrusaSlicer, Cura |

| Firmware | Klipper |

| Camera | 1080P, 30FPS |

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.