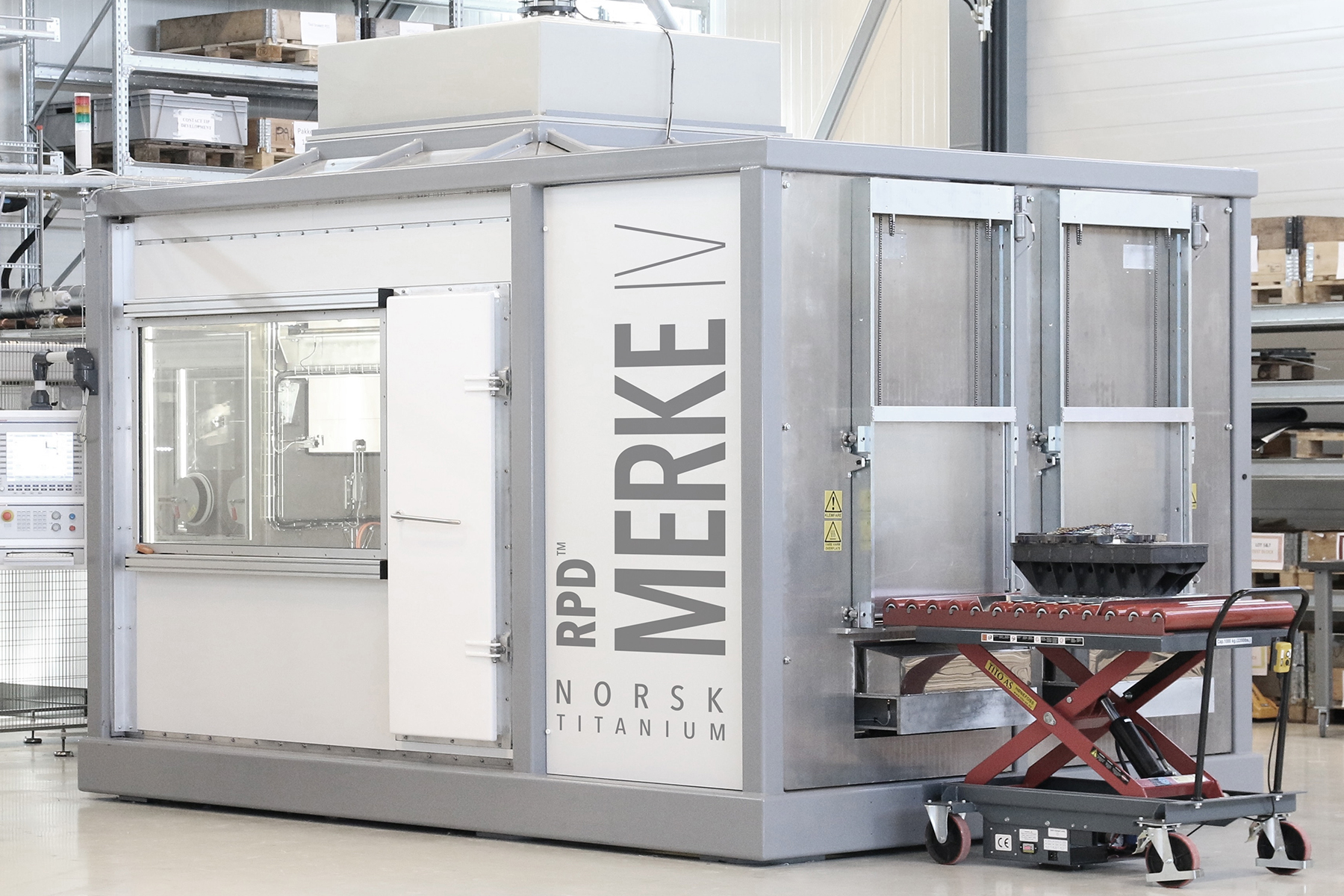

At its Plattsburgh facility in New York, Norwegian company Norsk Titanium has announced it will add 12 new metal 3D printers to its existing arsenal of Merke-IV machines.

Making the announcement at the opening of this year’s Paris Air show, the machines are part of a trade purchase agreement with Fort Schuyler Management Corporation (FSMC) and Empire State Development (ESD).

Empire State Development is an umbrella corporation that incorporates the New York government’s Department of Economic Development, while FSMC is not-for-profit corporation that “facilitates research and economic development opportunities.”

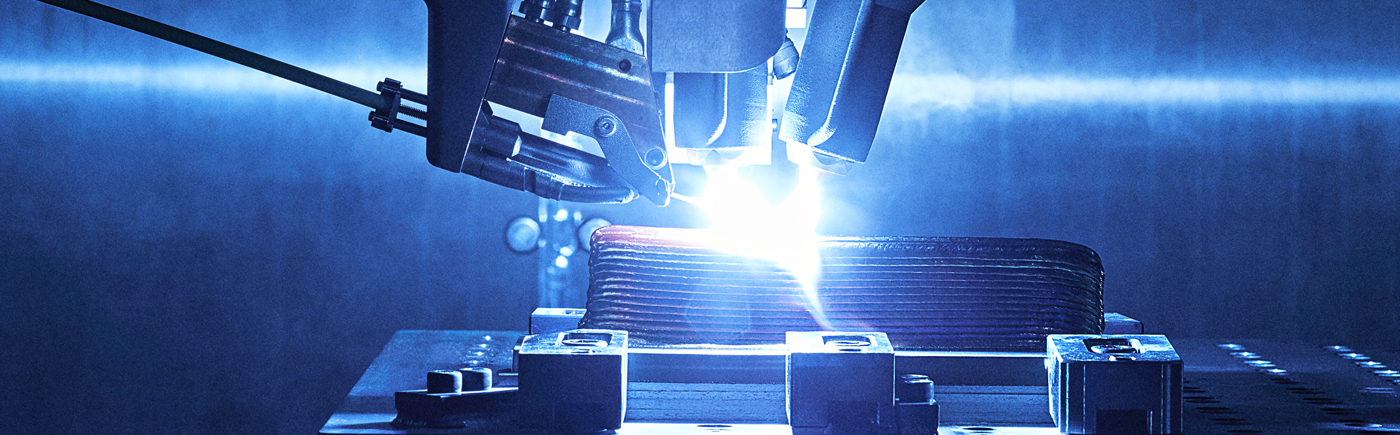

Norsk Titanium 3D prints metal parts using its proprietary technology, Rapid Plasma Deposition.

With this new agreement, the Plattsburgh facility will now have a total number of firm back-log and delivered machines of 32.

Ahead of the competition

The new machines will begin delivery to Plattsburgh in mid-2018 with each of the 3D printers capable of printing 20 tons of material a year. Expanding production is key for Norsk to stay ahead of the growing number of competitors, such as Chicago-based Sciaky and French company Prodways who last week entered the metal deposition arena.

Norsk Titanium recently announced production first FAA approved structural 3D printed titanium components for Boeing.

With this announcement, it is apparent that the State of New York is very keen for Norsk to increase its operations in Aerospace. Empire State Development President, CEO & Commissioner, Howard Zemsky explains further how the expansion will benefit the area,

Norsk Titanium’s new production and development facilities will bolster the North Country’s advanced manufacturing sector and the increasing demand for their products is great news for the local economy. Norsk continues to meet or exceed their commitments to the State and we look forward to their continued growth in Upstate New York.

Ideal Plattsburgh

Norsk Titanium explains it is based in the Plattsburgh, New York area for a number of reasons including transport infrastructure and close proximity to the aerospace supply chain community.

According to Warren M. Boley, President and CEO of Norsk Titanium, “Plattsburgh New York has been ideal for us,”

The State of New York has been a tremendous business partner and our growth in Plattsburgh is a testament to the value and opportunity that the game-changing Rapid Plasma Deposition™ (RPD™) technology delivers to customers.

In addition to this announcement, Norsk Titanium also recently received significant investment from Triangle Holdings to advance aerospace applications of additive manufacturing.

For all the latest metal 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows the New York purchase agreement signing. Photo via Norsk Titanium.