NASA has awarded a $100,000 grant to researchers at West Virginia University (WVU) to explore the use of 3D printed titanium dioxide foam aboard the International Space Station (ISS).

Research will take place at low Earth orbit on the ISS, with the foam intended to have application for solar cells, batteries and radiation shielding.

To conduct the Titanium dioxide (TiO2) foam research, WVU researchers will collaborate with materials scientists at the University of Rome Tor Vergata.

Space batteries

According to WVU, the porous TiO2 material has “great potential for space applications ranging from efficient solar cells to batteries and radiation shielding.” By 3D printing titanium oxide, the researchers will be able to create incredibly thin tubes which increase the speed of transferring energy. In 2014, researchers at Singapore’s Nanyang Technological University developed a titanium dioxide battery which could recharge up to 70% in two minutes and last twenty years.

NASA may therefore be exploring the use of titanium dioxide foam to replace existing batteries aboard the ISS with longer-lasting alternatives.

3D Printing Industry saw a 3D printed core metal foam made by the UK’s Renishaw at the Develop 3D event earlier this year. Renishaw are currently investigating applications for the metal foam.

Degradation characterization

NASA’s project with WVU will subject the titanium dioxide foams, which are 3D printed back on earth, to low-earth orbit conditions in order to evaluate the degradation of the materials. Returning from the ISS, the foams will then be characterized and WVU’s professor of industrial and management systems engineering, Majid Jaridi explains,

This degradation data will give significant early insight into the applicability of the TiO2 foam materials for the identified potential space applications before going forward and exploring their printing characteristics under microgravity conditions,

As Jaridi implies, future research hopes to explore the possibilities of printing the titanium oxide foams in space.

Metal foam

Metal 3D printing has paved the way for the production of advanced complex shapes. The lightweight structures could similarly have aerospace applications for their weight and strength characteristics.

While elsewhere, researchers have successfully formed free-standing graphene foam structures thanks to metal 3D printing and sugar.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

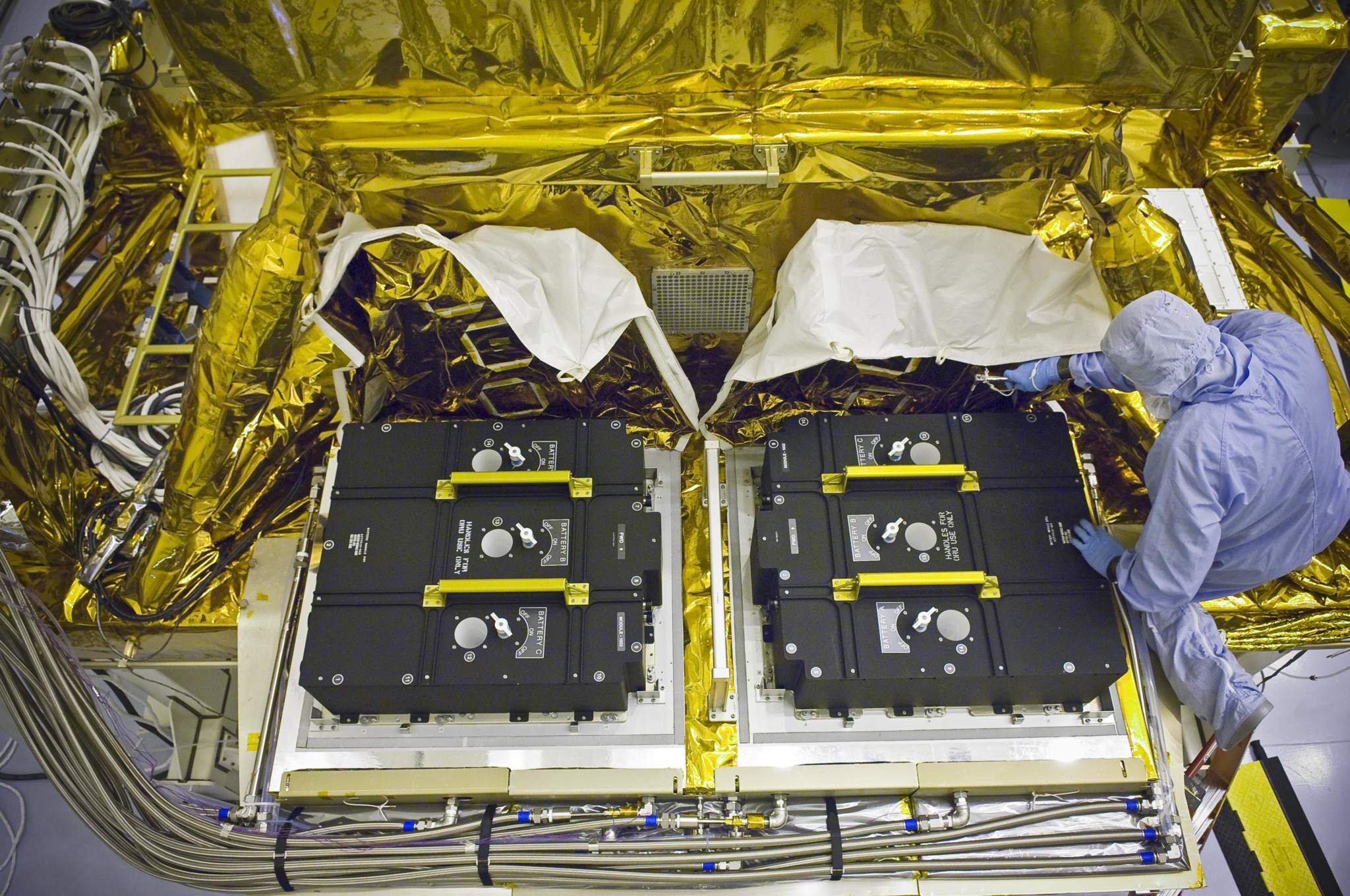

Featured image shows an astronaut undergoing a spacewalk aboard the ISS. Image via NASA.