Space manufacturing technologies leader Made In Space (MIS) will send the first ceramic manufacturing facility to the International Space Station (ISS) on September 29.

Part of Northrop Grumman’s 14th commercial resupply mission (NG-14), the Turbine Ceramic Manufacturing Module (CMM) will be the first stereolithography (SLA) printer to operate on-orbit.

“This mission is an exciting opportunity that further demonstrates the value of the ISS as a platform for commercial innovation and utilization,” said Michael Snyder, chief engineer at MIS and chief technology officer at Redwire, the parent company of MIS and aerospace conglomerate.

“Through our partnership with NASA, we are identifying and developing advanced manufacturing processes on-orbit that could yield sustainable demand from terrestrial markets. CMM is the first of several missions that could signal a new market for space enabled products.”

Additive manufacturing and the ISS

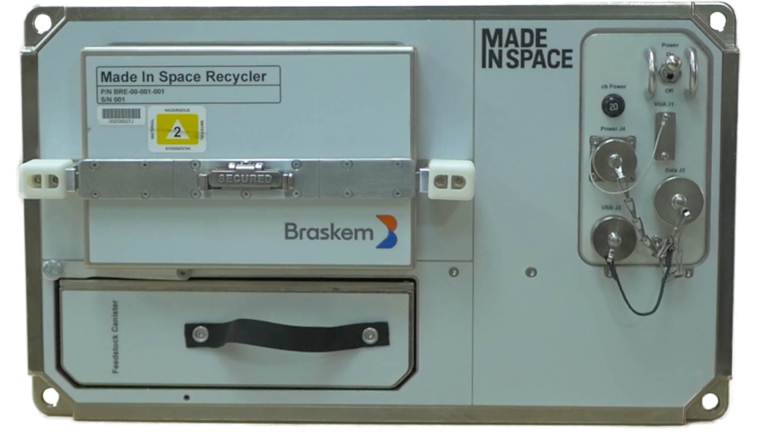

CMM will be the fifth facility MIS has launched to the ISS. In October 2019, MIS developed a plastic recycling facility for 3D printed parts on the station in partnership with Brazilian petrochemical company Braskem. The firm’s on-orbit and off-world operations date back to 2014 through its first and second-generation 3D printers.

Last year, NASA installed a Refabricator system by U.S-based aerospace company Tethers Unlimited on the ISS. The Refabricator system is a 3D printer and plastic recycler, developed with NASA’s Small Business Innovation Research Program grant. NASA has also partnered with KULR Technology Group to transport and store batteries aboard the ISS via its Thermal Runaway Shield (TRS) storage solution.

In July, industry, academic, and government experts descended upon the Center for the Advancement of Science in Space’s (CASIS) virtual Additive Manufacturing in Space Workshop. Attendees discussed additive manufacturing in the microgravity of space, and its potential for the development of new advanced materials.

Keynote speakers, including 3D Printing Industry’s own Editor-in-chief Michael Petch, touched on topics surrounding microgravity-specific materials and processes, in-situ resource utilization, and in-space production.

The CMM

According to MIS, CMM represents the realization of an ‘entirely new’ 3D printing technology aboard the ISS, and one which could heighten the space station’s commercial utilization.

The in-space manufacturing device aims to demonstrate the feasibility of manufacturing single-piece ceramic turbine components in microgravity environments. Fabricating turbine parts in this way could lead to them exhibiting higher strength and lower residual stress, due to removing gravity-induced defects such as sedimentation and composition gradients.

Developed in partnership with NASA’s ISS Research Integration Office at the Johnson Space Center, CMM’s SLA 3D printing method uses a UV-curable resin and a UV laser to print highly-accurate turbine components.

“The ceramic manufacturing technology that Made In Space is sending to the space station represents an expansion of commercial capabilities in orbit,” said Matthew Napoli, vice president of In-Space Operations at MIS. “The new capabilities that we are developing, with NASA and our technical partners, can yield game-changing innovations to deliver terrestrial benefits through space enabled manufacturing.”

CMM is the third ISS pilot payload developed through the partnership with NASA, with the aim being to scale up demand for commercial capabilities in low earth orbit (LEO).

Calfornia-based HRL Laboratories and Sierra Turbines were also involved in the CMM mission as technical partners.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The ISS Exterior. Photo via Roscosmos/ NASA/TTUHSC El Paso.