Automotive firm Larsen Motorsports has announced an ‘official affiliation’ with the Florida Institute of Technology.

Working with Florida Tech’s Center for Advanced Manufacturing and Innovative Design, the company will create and conduct several new collaborative design projects and interactive workshops in the name of educational development. The first of these projects will be the development of a 3D printed steering wheel.

The parties state that modular projects will be the backbone of the R&D partnership, whereby students from Florida Tech will work with employees from Larsen to innovate and design novel parts that advance both academia and industry. Beyond just motorsports, the projects will also yield benefits for aerospace, defense, and other manufacturing sectors.

Additionally, the upcoming projects are set to vary in both complexity and duration. Every time a new project is commenced, Larsen and Florida Tech will maintain comprehensive documentation for all of the relevant training procedures and project results.

Larsen Motorsports and Florida Tech

Based in Palm Bay, Larsen Motorsports is right in the heart of Florida’s Space Coast region. The firm has its own 30,000-square-foot manufacturing facility that aims to blend both traditional manufacturing and advanced production technologies such as 3D printing. Specializing in jet-powered drag racers, Larsen boasts a full suite of in-house concept, design, engineering, manufacturing, and operational capabilities.

With a noble focus on educational development, Larsen has dedicated half of its facility to educating visitors. The firm conducts daily guided tours, taking members of the public through the entire race car production workflow. Around 80% of the company’s workforce is also composed of student interns, predominantly from Florida Tech’s STEM disciplines.

Larsen is best known for its Dominator and Florida Tech jet dragsters. The latter is currently on the 2021 Generation 6 model, spanning 27 feet and sporting a General Electric J-85 engine with 5000hp. The jet-propelled car is capable of reaching speeds of up to 296 mph.

A composite steering wheel

Kicking the official affiliation off, the first project will see Brian Tocci, Director of Operations at Larsen Motorsports, work with student interns to design and 3D print a steering wheel for use on Larsen’s jet dragsters.

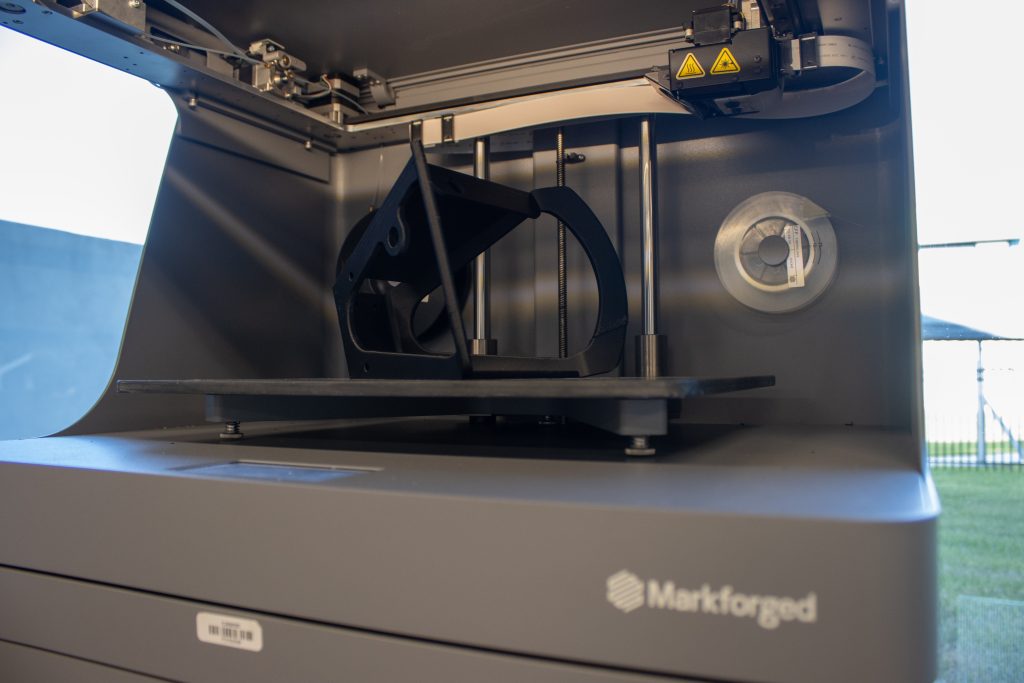

The Florida Tech interns have already developed the digital designs for the steering wheel using Siemens NX software and 3D printed a number of early prototypes. Tocci’s team will print the final end-use steering wheel on a Markforged X7 composite 3D printer using continuous carbon fiber-reinforced polyamide. The system is located at the Center for Advanced Manufacturing and Innovative Design.

Moving forward, Larsen has also expressed plans to further integrate additive manufacturing into its day-to-day automotive operations, with the Florida Tech affiliation aiding this goal. Future projects with the Center for Advanced Manufacturing and Innovative Design are yet to be announced.

Last year, Larsen also worked with high-precision micro dispenser manufacturer nScrypt to 3D print engine components for its dragsters. Utilizing nScrypt’s ‘nRugged’ system, the firm was able to replace the outdated gaskets on the fuel pumps of its jet-powered cars with more durable fabricated seals. The seals underwent a six month testing process and proved to be 100% reliable in harsh conditions.

Elsewhere in the motorsport sector, cold Spray 3D printer manufacturer SPEE3D recently showcased an impressive new batch of metal racing car parts 3D printed for the 2022 Australian Grand Prix. Developed for client Garry Rogers Motorsport, the parts varied from a large 6.8kg structural element to small wheel inners – all 3D printed on the firm’s WarpSPEE3D system.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Larsen Motorsport’s Florida Tech dragster. Photo via Larsen Motorsports.