Abyan Building Construction Company (Abyan) has built what it claims to be the “world’s first” on-site 3D printed large water tanks in Kuwait using COBOD’s construction 3D printer.

Printed for Kuwait United Poultry Company, these two tanks are designated for providing drinking water to chickens at one of their numerous farms in Kuwait. Leveraging the speed and design freedom of 3D construction printing, the tanks were constructed more rapidly, economically, and sustainably than traditional formwork methods. With dimensions of 4.5 meters in height and a diameter of 7 meters, these tanks were 3D printed in just five days.

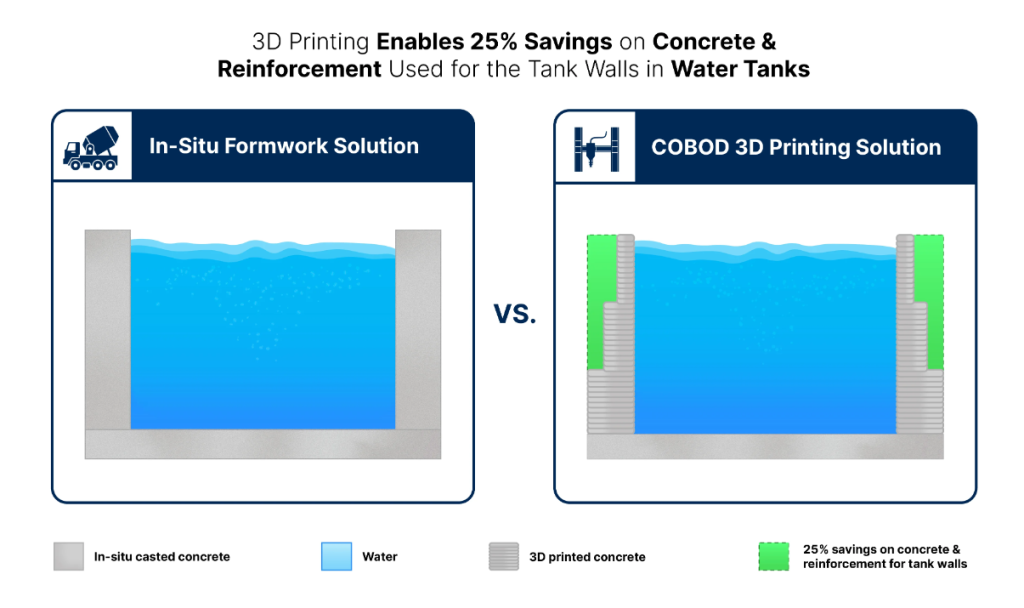

As per the company, this structural engineering is demonstrated in the diagram below, indicating that these tanks possess varying wall thicknesses: 40cm at the bottom, 30cm in the middle, and 20cm at the top. Consequently, this approach resulted in a 25% reduction in concrete and reinforcement usage for the walls, compared to a uniform casting of 40cm walls throughout.

Mr. Muhammad Al-Hussain from Kuwait United Poultry Company, said, “We are very happy about the results of this project and for the huge savings in time. We will surely repeat this method in the future and get more 3D printed tanks for our many chicken farms.”

3D printing optimizes tank design and construction

Employing the D.fab solution and printing equipment developed by CEMEX and COBOD, the tanks were 3D printed using an economically feasible C40/50 concrete mixture, prepared on-site with 99% of locally sourced raw materials. In a bid to expedite the construction process, Abyan advocated for the use of macro fibers to reinforce the concrete. This decision posed a challenge as macro fibers had not been previously utilized for reinforcing 3D printed structural constructions, presenting unique requirements from Abyan.

Henrik Lund-Nielsen, Founder & General Manager of COBOD said, “Abyan pursues real innovations, which we really want to support and they wanted to try to avoid using any hard reinforcement in the walls, and just add fibers to the concrete. Of course, this challenged us a lot, but together with Cemex, the three of us were able to find a very good solution, which now can be replicated elsewhere in the future”.

According to the company, traditional tank construction relies on formwork and concrete, necessitating uniform wall thickness due to formwork limitations. However, 3D construction printing allows for flexible wall thickness adjustments by engineers. Given the heightened stress at the tank bottom from gravity and water pressure, thicker walls are needed there. With 3D printing, it is possible to thicken the bottom walls while tapering towards the top, saving materials and improving both economic and sustainable outcomes.

3D printing emerges as a better solution for construction

Many companies have been ditching traditional methods to streamline construction by turning towards 3D printing. One of the latest examples is Builtech Construction Group, in partnership with the City of Walnut and the Los Angeles County Fire Department, constructing the U.S.’s first fire-resistant, onsite-built concrete accessory dwelling unit (ADU).

Led by Builtech, the project includes plumbing installation and on-site 3D printing of concrete walls using RIC Technology‘s robotic arm. Featuring 2 bedrooms and 2.5 bathrooms, the 1200 sqft ADU aims to mitigate wildfire risks by employing non-combustible materials and innovative architectural designs, thus enhancing resilience and reducing recovery costs.

Last year, Larsen & Toubro (L&T) and Indian Institute of Technology Madras (IIT Madras) collaborated to construct India’s first 3D printed post office in Bengaluru’s Cambridge Layout. Completed in 43 days, two days ahead of schedule, the 1,021 sqft structure showcased a 30-40% reduction in expenses compared to conventional construction. Coupled with specialized rapid-solidifying concrete, a robotic printer’s systematic layering of concrete ensures a seamless, jointless structure with curved surfaces.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the world’s first on-site 3D printed large water tanks for chicken drinking water made for the Kuwait United Poultry Company. Representatives of Abyan, COBOD, and Kuwait United Poultry Company are seen in the front. Some chicken farms are seen at the top of the picture. Photo via Abyan.