With The KODAK Portrait 3D Printer, Kodak has entered the 3D printing market to raise the bar and set a new standard for professional 3D printing. Conceived primarily with education, design and engineering professionals in mind, the KODAK 3D Printing Ecosystem offers reliable and accurate 3D printing.

The KODAK Portrait 3D Printer is now available for pre-sale at a 35% discounted price, but only until the first 500 units sell out. Customers will pay only $1819 for the dual extruder, fully enclosed 3D printer that will be launched at a manufacturer’s suggested retail price (MSRP) of $2799 at CES in January 2018.

What makes the deal even more appealing is that every customer who buys a printer now gets a 30% discount in all filaments purchased during 2018. Kodak 3D printers pre-ordered now will ship in March 2018.

A printer that stands out from the crowd

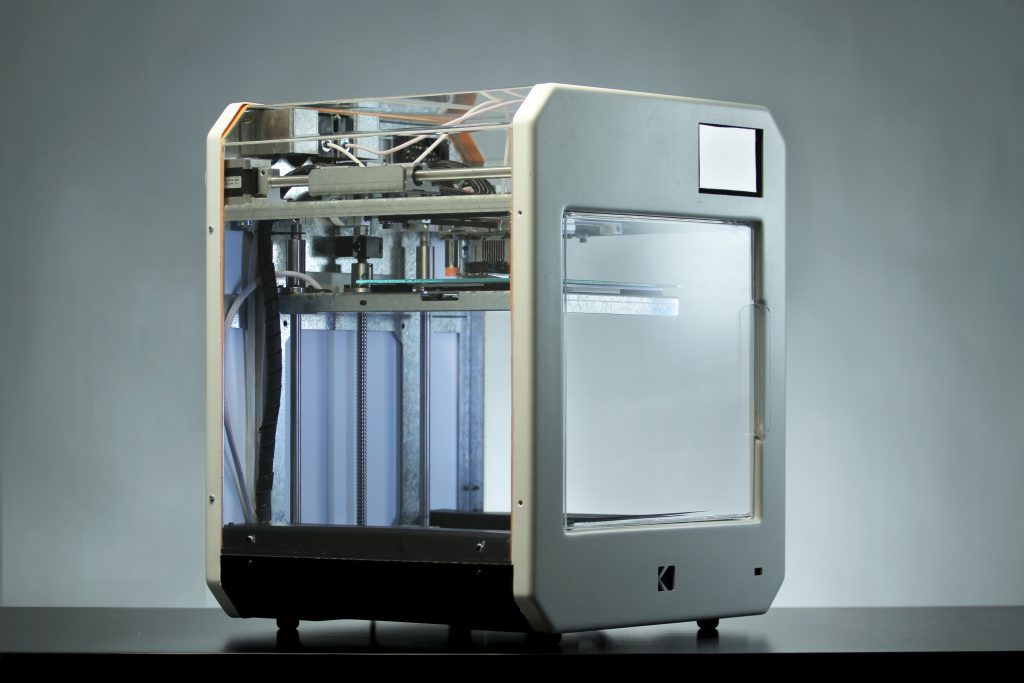

Kodak’s first professional desktop 3D printer incorporates numerous features that make it stand out from the crowd of other desktop machines currently on the market.

The printer has an above-average print volume of 200x200x250mm (8’’x8’’x10’’), making it ideal for the majority of conceptual models and functional parts. At the same time, it fits comfortably on a desk and can be transported by a person or two.

Many 3D printers are open, very few are fully enclosed, and only a handful of them have effective air filtering systems fitted to keep the air clean and odor-free, important especially when using ABS filament. The Portrait features a HEPA/activated-carbon filter, making it suitable for safe use in classrooms, laboratories and offices.

The fully enclosed print area also improves safety and print quality keeping fingers away from hot or moving parts, and reducing the noise. It also keeps in warm air and keeps out cold drafts, which can create warping in large printed objects. To further minimise warping, the temperature of this enclosed chamber is actively regulated with an extractor fan.

Dual material, dual colours, continuous prints

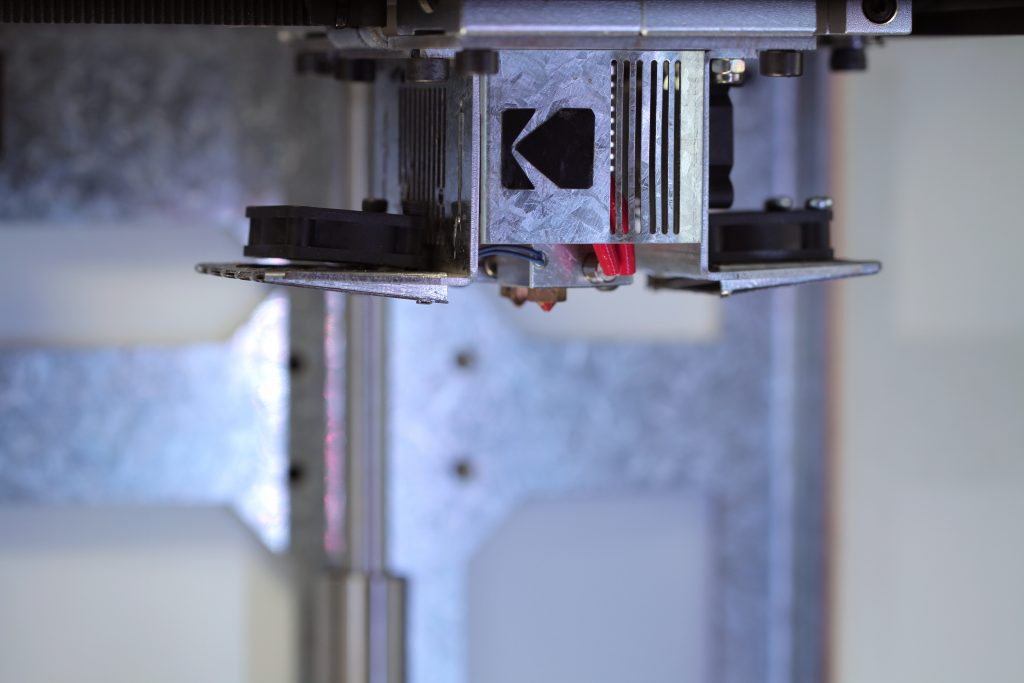

Very few desktop printers have dual material or color printing capabilities. The Portrait, however, has dual extruders with dual nozzles. It includes some key features that are needed for this configuration to work more effectively than other printers that are incapable of dual printing.

To allow high quality dual color prints, a nozzle-wiping mechanism helps avoid color contamination. An end-of-filament sensor helps ensure that long prints are not ruined if either material runs out.

It also provides the unique ability to use the same material in both extruders and to have one continue printing when the material runs out on the primary extruder. This lets the user fully use up a spool of filament, safe in the knowledge that printing will still continue when it runs out. This capability is essential for making large, dense, long-printing objects,

A precision magnetic-attachment quick-exchange mechanism allows hot ends to be substituted easily. This allows clogged hot ends to be quickly detached and replaced without the need for tools. You can also exchange a hot end with different nozzle configurations.

Accessible professional printing

The Portrait has several important features for ease of use even by inexperienced personnel. It features an automatic and contactless print bed leveling capability using a capacitive sensor.

Prior to each print job, the printer will measure the print surface at several points to determine any tilt (which is always present) and calculate a correction that will make the printed object truly perpendicular to the print surface. Most firmware will only make a correction in the Z direction, which would make a cube print with angled walls.

The print surface is firmly held by magnets, and easily detached for cooling, cleaning or for removing the printed object. With the second supplied print surface you can continue printing right away, while processing the last printed object.

Low moisture, accurate filament

Kodak’s 3D printing filaments have some of the lowest moisture rate in the market, as well as the highest roundness and diameter accuracy. Low moisture is important to high print quality. When humid plastic is melted, the polymer chains tend to break at a molecular level, altering physical properties and resulting in poor prints.

This is not only the case in hygroscopic (atmospheric water absorbing) materials such as nylon or PVA, but in most 3D printing materials. This makes a low moisture absorbent material essential for high-quality prints.

To preserve filament quality and to help ensure repeatable results, Kodak 3D printing filaments fit inside the supplied airtight protection cartridges, which feature humidity desiccants. When filament is removed from its special airtight foil packaging, it is placed in these cartridges, which connect to the extruders, forming a system where the filament is never exposed to the ambient humidity or dust.

Sturdy, stable and serviceable hardware

The Kodak Portrait 3D printer is rigidly built, using precision laser-cut steel sheets. Thick guide rods and industrial bearing blocks move the print carriage smoothly and precisely, even at higher speeds and accelerations. Z-axis movement is completed via a ball-screw, which will neither wear out with constant bed-leveling, nor bend under the weight of the print platform.

All of the Portrait’s electronic components are hidden inside the printer but easily accessible for servicing under a single removable panel. Efficient classroom use can be guaranteed with its highly visible exterior. 5 color LED lights not only illuminate the printer while it works, but also convey printer status information at a distance.

Game-changing software and connectivity

Printer software differentiates the KODAK Portrait 3D Printer from its competitors. Printer movement is fulfilled by a dedicated controller board, while a separate controller with a 5” color touch screen provides a user interface and displays printer connectivity.

Monitoring the printing process, rating the print’s quality, tracking print-time per user and allocating printer costs depending on usage are possible with the KODAK Portrait’s software.

The printer software provides advanced multi-user features. Users can log in and gain immediate access to email, file-sharing services or social media. This is particularly useful in a classroom environment. An individual student or a generic user representing a particular class may take a printable file from Dropbox, post the finished object’s time-lapse movie on Instagram and tweet the print results, for example.

The first 500 units of the KODAK Portrait 3D Printer are now available at a 35% discounted pre-sale price of $1819. But an even bigger saving to be made on the early bird sales is the 30% discount in all 2018 filament purchases. Click here for more information.

For more offers on 3D printers, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the KODAK Portrait 3D printer on display. Photo via Kodak.