Ahead of Formnext 2023, 3D Printing Industry spoke to the winners of the Formnext Start-Up challenge.

Stephan Körber, Mathias Czasny, and Moritz Ebeling-Rump, are the founders of Endless Industries, and aim to redefine the composite manufacturing industry by integrating the technology developed during Czasny’s PhD with the capabilities of additive manufacturing.

Körber, the CEO of Endless Industries, reminisced on their academic days at the Technical University of Berlin (TUB), where they first met. “[Mathias] showed me how to build carbon fiber layers and make parts from carbon fiber,” he shared. With a passion for technology and business, Körber recognized the untapped potential in many university-developed technologies, stating, “There are so many technologies at the university being developed. And it’s kind of a shame that they’re not seeing the market.”

On the other hand, Czasny, the firm’s CTO and a material scientist has been driven by the challenge of simplifying the complicated and labor-intensive traditional composite manufacturing process. Explaining the contrast between additive manufacturing and traditional composite methods, Czasny said, “In composite industries, everything is so complicated, we spend weeks, months to create, but it’s very difficult, very complicated, very expensive.”

Czasny’s research at TUB centered on “how we can produce composite parts by additive manufacturing,” with the goal of achieving the quality of products used in high-end applications like Formula One cars or aerospace technologies.

The trio saw the chance to combine their expertise and ambition; they sought funding and support, leading to the inception of Endless Industries.

Now, with a robust roadmap and their initial customers onboard, Endless Industries is set to explore the horizons of what’s possible in composite manufacturing.

Vote now in the 2023 3D Printing Industry Awards.

Endless Industries Focuses on Augmenting Existing 3D Printers with Advanced Continuous Fibre Tech

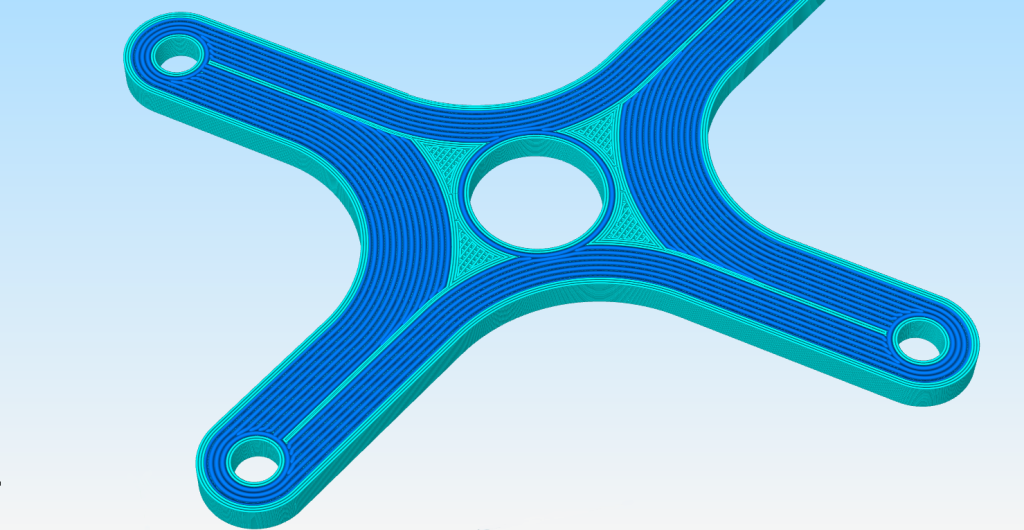

Endless Industries is not just about developing a new 3D printer but about enhancing the existing machinery in the market with its innovative continuous fiber technology. Discussing the evolution of their approach, Stephan Körber, the CEO, shed light on the company’s strategic shift from building an entirely new printer to maximizing the potential of current industrial-grade 3D printers, using its proprietary material, software and a patented nozzle capable of simultaneous carbon fiber and plastic processing.

“There’s so many already great printers on the market that we actually could equip with our technology,” Körber says. This realization prompted the team to rethink their strategy, especially after receiving overwhelming feedback at last year’s Formnext.

Shifting gears from producing a new machine, Körber highlighted, “The business model is basically that we integrate our continuous fiber technology into 3D printers.” This integration would not be confined to standalone printers but could also encompass robots and industrial production machines. The company plans to provide the materials, software, and know-how to ensure seamless compatibility of its continuous fiber technology with these machines.

Endless Industries Advanced Composite Fabrication

The company aims to address the challenges faced in the composite fabrication industry with innovative solutions, especially around fiber cutting and material management.

Mathias Czasny, the CTO, highlighted some of their technology’s unique features: “We have patents on the cutting mechanism and over the processes. We have a cutting mechanism located directly in the hotend, which is different from our competitors.” He explained the benefits, “Because the polymeric melt is already liquid as well…you cut only the carbon fiber, you don’t cut the whole filament.” This allows Endless Industries to employ thicker fiber bundles, increasing the output per hour.

Czasny emphasized the company’s approach to material management, “We are using filaments which are already infiltrated with the polymeric material with the matrix material.” This tactic aims to simplify the process for end-users by separating material manufacturing from material processing.

On the software front, the company has developed a product that facilitates the precise layering of carbon fiber in parts. The software pre-processes design data, ensuring carbon fiber orientation aligns optimally with strength requirements. This caters to two distinct customer groups: those looking for quick and easy printing solutions and composite engineers seeking fine-grained control for optimized applications.

The firm aims to bring together the best of composite engineering and additive manufacturing, catering to the mass market and specialist engineers. With their innovation, Endless Industries is positioned to redefine the future of composite part production.

Endless Industries Introduces Novel 3D Printing Technique

The company has introduced a unique fiber-cutting method, distinguishing itself from the traditional spool and blade system. When discussing their technology, Mathias Czasny, the CTO, elaborated, “In the hot end itself, it’s not a plate it’s a cylinder which is movable, and there are two holes inside it, and if you turn the cylinder, the two holes are not aligned. So, you cut the fiber directly only by rotating the cylinder.” This mechanism offers a streamlined and efficient method for cutting fibers during printing.

Further highlighting the firm’s distinctive approach, Czasny added, “We are using mainly 3k carbon fiber, which means 3000 single fibers in a fiber bundle.” In comparison, most competitors typically utilize “1k or 1.5k for carbon fiber bundles,” or roughly 1000 to 1500 fibers per bundle.

Endless Industries’ innovation is a leap forward, aiming to optimize efficiency and precision in 3D printing processes. Their technique simplifies the cutting process and promises better control over fiber integration, potentially setting new industry standards.

Endless Industries differentiates itself in the saturated 3D printing arena, aiming not to compete with stalwarts but to collaborate and complement. Stephan Körber, the CEO of Endless Industries, explained, “We don’t see ourselves as a direct competitor to Markforged. We’re more like technology providers. We provide the solution for other 3D printing companies.” He further emphasized the complexity of integrating fiber cutting and software technology into a 3D printer, a hurdle many manufacturers might not have the resources to overcome.

He elaborated on the company’s vision, “Our solution with thicker fibers makes more sense, as thicker strands mean a higher build rate of your part.” This notion of leveraging thicker fibers has significant implications for large-scale 3D printing, opening up a niche segment for the firm. Körber added, “We want to partner with large-scale industrial-grade 3D printer manufacturers. We see that as something we can help and bring the technology forward.”

Additionally, the firm’s deep expertise in materials science enables it to offer a broader material palette, which can be tailored to specific applications. “We not only have thicker fibers for bigger parts, but we also offer a more varied material choice. We can also develop materials specialized for purpose,” Körber noted.

Advanced Polymers and Natural Fibres for 3D Printing

Endless Industries is delving deep into the potential of polymers and fibers to revolutionize 3D printing applications. Mathias Czasny, the company’s CTO, highlighted the nuances of choosing polymers, saying, “We started with PETG, which is very simple… you have no problems with moisture in the process, which makes it much easier for people who are not very trained to work with this machine.” He elaborated on the company’s forward-looking approach, noting a shift in the automotive industry as they transition from combustion engines to electric motors, necessitating a change in materials used. Czasny added, “Polycarbonate is very interesting for its surfaces because of its high transparency, giving a good look and feel.”

The company recognizes the importance of more advanced polymers, such as PEEK, used in aerospace applications. “Some competitors are not focusing on endless carbon fiber 3D printing if they cannot support PEEK as a matrix material for composites. They’re waiting for this technology,” said Czasny, emphasizing the need for partnerships for long-term development.

Körber also pointed out an emerging trend, stating, “We get lots of questions for natural fibers combined with naturally degradable plastics.” He highlighted the environmental edge, “With thermoplastics, for example, recyclability is a big thing. With thermoplastics, you can shred it and produce your filament out of it.”

Czasny explained their progress: “We have a robotic gripper reinforced with carbon fiber. The material combination was PETG plus carbon fiber because PETG is simple to print, and carbon fiber offers high stiffness, allowing for swift and vibration-free movement.”

Czasny also touched upon the challenges in the rail sector. He highlighted a part from a German train manufacturer, explaining that “carbon fiber is not the right material choice” due to potential fumes in the train cabin. Instead, the goal is to incorporate glass fiber and other flame-retardant materials, like modified polyamides, focusing on higher temperature resistance.

Czasny stated, “The big trend in additive manufacturing is to provide the right materials.” He emphasized the importance of having the correct material choice, whether for aerospace, medical, or everyday applications, to ensure safety, functionality, and cost-effectiveness. “We are working with the raw carbon or the fibers from the fiber manufacturers. And we are working with the raw polymer from the polymeric manufacturers.” Delving deeper into the intricacies of the process, Czasny shared, “Flame retardant materials [are] only an additive, so you add this only to your material, and you compound it to make basic materials.”

Endless Industries employs a dual-strategy approach rather than pioneering entirely new compounds. On the one hand, they’re leveraging existing materials in the market, which Czasny believes is “much easier for us.” He pointed out, “There’s a lot of compounds on the market, so that we can use a lot of there.” On the other, they’re exploring the development of their proprietary formulations.

However, Czasny also emphasized the complexities of merging polymers with fibers, noting the challenges of achieving an optimal bond. He highlighted, “The problem is, if you compare the [viscosity] of plastic material is in the viscosity range 1000 times higher than the epoxy resins.” Drawing from his PhD work, Czasny underlines the importance of understanding these processes’ intricate chemistry and physics, suggesting this expertise is pivotal for the firm’s advancements in material development.

Endless Industries Commercializing 3D Printing Technology

Körber, CEO of the company, shared that they have successfully achieved material production on a limited scale and are developing a more extensive machine. “Last year, we went out, looked for partners, and found the first partner,” Körber revealed, hinting at a forthcoming announcement.

While Körber remained tight-lipped on the partner’s identity, he provided a glimpse into their collaboration’s scale, referencing “big machines, half meter by half meter, in build volume.” He commented on the quality of these machines, describing them as “really, really high-quality machines.”

The CEO emphasized the company’s ambitious growth trajectory, noting, “First partner on board, first revenues already in the bank.” However, he also highlighted their openness to further collaborations, especially with industrial-grade 3D printing manufacturers and robotic 3D printing. “When you leave the two-dimensional space, you have more capability of the fiber,” he explained, suggesting a multi-dimensional approach could amplify the potential of their technology.

Körber concluded, “I think a broad range is the best range of machines… to bring the technology forward,” signifying their commitment to offering versatility and choice to end customers.

Endless Industries will showcase its latest continuous fiber 3D printing advancements at this year’s Formnext event. Operating from a joint booth representing several Berlin and Brandenburg companies, CEO Stephan Körber mentioned, “We hope to show more of the technology. We will have one of our printers there so people can see what the technology is capable of.”

In discussing the company’s trajectory, Körber revealed a dual approach: mastering the “Champions League” of high-strain materials such as carbon fiber plus PEEK and offering on-demand manufacturing services. “[Companies] want to try before they buy. And that’s what we currently offer,” he said.

Sketching a five-year plan, Körber voiced his ambition: “We want to be the one-stop shop for everything related to continuous fiber technology. So software, hardware, and materials.” He sees vast potential in the market and envisions Endless Industries as a pivotal player, aspiring for the firm to be the go-to entity in the continuous fiber 3D printing sector. He added, “The business plan says we will have around 30 employees. There’s so much potential in the technology and we want to be one of the giants in the field.”

Körber said, “There are currently very few manufacturers in the 3D printing space that I know of that offer fiber plus PEEK,” highlighting the immense potential for high-end applications.

Czasny elucidated the growing applications in aerospace, noting the Airbus 350, already comprising 50% carbon fiber materials. He indicated a shift towards “thermoplastic technologies” from thermoset materials for greater recyclability.

Yet, despite these technological inroads, quantifying market size still needs to be discovered. Czasny underscored the complexity of measuring potential, especially when juxtaposing their technology with pre-existing methods such as injection molding.

In wrapping up, Körber expressed enthusiasm about their participation at Formnext, acknowledging the value of the industry community and the insights they gain from regular meetings. He said, “It’s cool to be a part of, and we’re really happy and looking forward to it.”

Visit Endless Industries during Formnext 2023; find them in Hall 11.1, D31.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Endless Industries Team (left to right) Stephan Körber, Dr. Mathias Czasny, Dr. Moritz Ebeling-Rump. Photo via Endless Industries GmbH.