A conversation with Gary Turner, the Managing Director of Additive Manufacturing for Ricoh North America, outlined the company’s 3D printing strategy. “Our approach in North America to additive manufacturing is a services-based approach,” Turner began, noting that Ricoh USA isn’t focused on selling 3D printers, but instead concentrates on providing services that drive the adoption of 3D printing for its customers.

Turner expressed concern over the slow uptake of additive manufacturing in some sectors. “We’ve been talking for years about the promise of additive but it hasn’t quite taken off,” he remarked, pointing to challenges like complex workflows, cumbersome software applications, and a shortage of skilled workers in the industry.

However, Ricoh North America identified the healthcare sector as a promising avenue for additive manufacturing, driven by Ricoh’s overarching philosophy around innovation. Turner explained, “Ricoh’s philosophy is to focus on societal challenges. Through solving those challenges, we launch new businesses.” He highlighted the particular interest of Japanese companies in healthcare due to the aging population in Japan.

Ricoh’s research showed that while there are clear benefits to using 3D printing in healthcare, its adoption remains low. Turner stated, “Between five and 10% of surgeons in the US have access to patient-specific 3D printing solutions in their hospital system.” This led Ricoh to develop an end-to-end workflow designed to be easily and cost-effectively adopted by hospitals.

The ultimate goal for Ricoh is broader than just producing 3D printed anatomic models for surgeons. “We’re trying to set up programs that allow access for surgeons to these technologies,” Turner emphasized. He is particularly passionate about democratizing access to 3D printing in healthcare. Presently, only patients who can afford to visit premier medical centers can access this technology. “It shouldn’t be like that,” Turner argued, “everyone should have access, and it should be affordable.”

Read more on the Ricoh metal binder jetting 3D printer.

Ricoh and Stratasys Partner on 3D Printed Medical Devices

The AM Managing Director highlighted the company’s deep ties with 3D printing giant Stratasys. Turner noted, “Ricoh has a long history with Stratasys,” revealing that “the printheads that go into the old Objet technologies are Ricoh printheads”. He added, “Ricoh was a close collaborator with Objet when they designed those devices years ago.” This longstanding collaboration has evolved into a partnership focusing on polymer technology for producing anatomic models.

Turner outlined the initial collaboration as the foundation or “minimally viable product” and the recent entry to a bigger and bolder project. “The next phase,” he elaborated, “is point of care manufacturing,” indicating a move towards distributed manufacturing. An interesting fact was brought to light when Turner mentioned that “Ricoh is one of the largest managed services providers in North America.” With over 6,000 employees attending customer sites daily, Ricoh sees a clear path to creating an extensive manufacturing network, ensuring quality and consistency.

Ricoh’s ambitious plan involves offering hospitals an onsite point-of-care center. This facility managed and staffed by Ricoh, would operate under the company’s quality management system. Its main function? “To produce 510 (k) cleared medical device 3D printed anatomic models on-site”, Turner affirmed. He envisaged these facilities equipped with Stratasys technology and 3D printing technicians working directly on hospital premises.

Ricoh Envisions On-Site 3D Printed Medical Device Hubs in Hospitals

Turner expressed the necessity of biomedical engineering and clinical staff collaboration for seamless operations: “Engineers won’t be experts in every anatomy,” he said. However, the advantage lies in having “a network of experts on-site” which facilitates rapid turnaround times and crucial collaboration with physicians.

Understanding doctors’ time constraints, Turner emphasized the need to streamline access. “Physicians don’t have time,” he noted. The ultimate goal? “Make it accessible and easy.” By integrating these anatomic labs and modeling labs within the hospital corridors, surgeons can have impromptu interactions, increasing the chances of adopting the technology.

One of the key attractions of Ricoh’s proposed point-of-care centers for hospitals is the turnkey nature of the service. “Hospitals won’t have to hire experts or set up a quality management system,” Turner explained. Instead, they can lean on Ricoh, who will ensure FDA registration, adherence to quality systems such as ISO 13485, and the production of cleared devices on-site.

Turner’s long-term vision is ambitious: “My vision for the future is to have hundreds of these sites in hospitals across the country, functioning as a network of distributed manufacturing operations right at the point of care.” This approach, he believes, will revolutionize how surgeons interact with and utilize additive manufacturing technology.

Ricoh’s ‘Easy Button’ for Medical Imaging: An Emerging Tool for Surgeons

Turner also discussed the advancement of Ricoh’s PACS Print Gateway tool. This tool interfaces with the PACS system, allowing surgeons to easily transfer MRI or CT studies to Ricoh.

The PACS Print Gateway, provided by Merge by Merative, can be integrated into various enterprise-wide viewer systems at hospitals. Turner elaborated on its ubiquity: “They [surgeons] click the link in the PAC system, and it initiates an order with Ricoh for a patient-specific anatomic model.”

Recently, the company announced a partnership with Materialise which will provide software supporting Ricoh’s HIPAA-compliant, ISO 13485 certified 3D medical manufacturing center for the development, design, and production of 3D-printed anatomic models.

Ricoh’s 3D Anatomic Models Gain Traction Among Surgeons

Addressing the labor-intensive process of transforming DICOM data to 3D print, Turner acknowledged the evolution of the process, saying, ” We improve that process significantly, which has brought the cost down.”

The potential market scope alludes to the vast possibilities in the realm of surgeries. Turner mentioned the Radiological Society of North America and its special interest group, hinting at the larger community and networks taking a keen interest in 3D printing’s medical applications.

According to Turner, “One of the things that [the Radiological Society of North America] have done is they’ve taken a look at the use of anatomic models and identified a list of procedures that can benefit most from 3D printing.” Such a list points to the vast potential for 3D printing’s incorporation into a myriad of surgical procedures, with numbers possibly running into the “hundreds of thousands across the country.”

However, Turner also highlighted a pressing industry challenge: “One of the other challenges we have with adoption is reimbursement.” To counteract this, Ricoh is initiating a randomized control trial to demonstrate the tangible benefits of 3D models in surgical applications. Turner mentioned, “We’re working with three different hospital systems to do that study, which we think will take about nine months.”

Beyond the medical realm, Turner shared that Ricoh is also venturing into “rapid prototyping” and managed 3D Print Services for engineering. Looking forward, Turner indicated that the North American arm of Ricoh will continue to leverage its “managed services infrastructure to help drive adoption and use of 3D printing both for rapid prototyping as well as end-use parts.”

He stressed that the objective is to “take the burden off on the end user” and let them concentrate on their primary business operations, implying a services-centric approach for the future. The conversation underscored the commitment and innovative strides of Ricoh in utilising 3D printing for both the medical and engineering sectors.

Ricoh North America Elevates Its 3D Printing Strategy, Eyes Medical Sector

Ricoh North America is on the cusp of a transformative move into the 3D printing space within hospitals, spotlighting their ‘Centre of Excellence’ initiative. “We have the infrastructure to build on top of,” remarked Turner.

Regarding the ‘Centre of Excellence’, Turner revealed, “We’re setting up our center of excellence at a hospital location.” Designated as Ricoh’s maiden point-of-care center funded by the company, the center will be functional by the end of this year. He further hinted at a forthcoming announcement about the exact location. “It will be our first on-site implementation… intended to be that physical embodiment of the competency program and the best practices,” he added.

The progress of Ricoh’s entry into the 3D printing arena could be likened to a juggernaut building up speed. Turner, who has been associated with Ricoh for 27 years, acknowledged the dual-edged nature of pioneering a startup-like venture within a conglomerate, “You benefit, but you also have the headwind of a big company.” However, he voiced optimism about Ricoh’s direction, buoyed by significant support from US leadership and headquarters in Japan.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

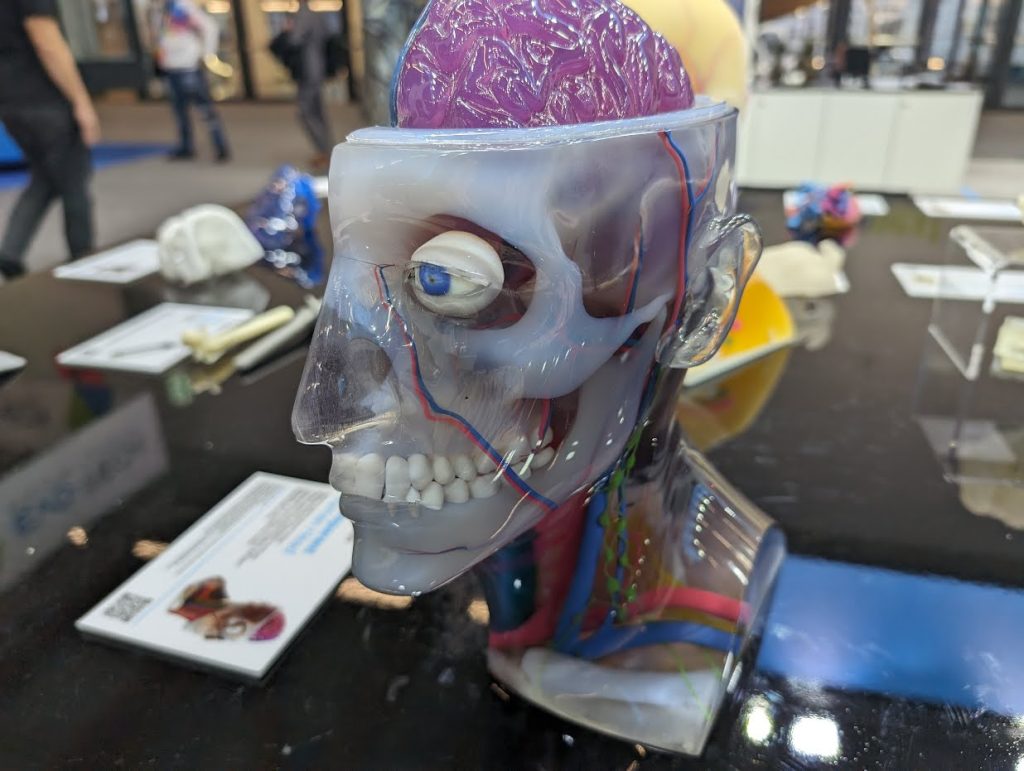

Featured image shows a Stratasys 3D printed model on display at Formnext 2023. Photo by Michael Petch.