Ahead of the inaugural online event Additive Manufacturing Advantage: Aerospace, Space, and Defense 3D Printing Industry is running a series of articles focused on the application of 3D printing in these critical sectors. Register now for AMAA 2024 on July 16th to hear more insights from sector leaders.

During a conversation at RAPID + TCT 2024 Chris Schuppe, CTO of metal 3D printer manufacturer Colibrium Additive, discussed the benefits of the company’s electron beam melting (EBM) technology for aerospace and defense applications.

According to Schuppe, 3D printing for aerospace and defense verticals has matured from “infancy to adolescence.” However, he believes there is “a long road to adulthood,” with work still required to achieve mass adoption.

He introduced Colibrium’s new product offerings launched at North America’s largest trade show. This included a new entry-level EBM 3D printer and an additive manufacturing software update which enables support-free 3D printing of complex metal parts.

How to overcome challenges in aerospace and defense was also covered. Schuppe highlighted how Colibrium technology meets demanding certification requirements, and emphasized the importance of advancing design for additive manufacturing (DfAM).

The CTO also outlined Colibrium Additive’s future roadmap, sharing a critical perspective on the ongoing 3D printer “laser wars.” Schuppe highlights the diminishing return of endlessly adding more lasers to industrial systems, proposing a more pragmatic approach which balances productivity with part quality.

Colbrium Additive unveils new technology at RAPID + TCT 2024

At RAPID + TCT 2024, Colibrium Additive launched the Spectra M, its new EBM 3D printer. This system addresses the demand for EBM capabilities in a smaller build volume. Measuring Ø270 x 430 mm, the Spectra M’s build envelope is more compact than most other options in the EBM market.

According to Schupe, the Spectra M stands out as an “entry-level” metal 3D printer, increasing the accessibility of EBM technology to a broader range of users. “It has a similar footprint to the spectrum L, offering a smaller build area and a lower price point” he explained.

This aligns with the broader industry trend of making industrial additive manufacturing technologies more accessible. Schuppe believes Spectra M’s accessibility is crucial for scaling to end-use production applications and getting more 3D printers onto factory floors.

Another significant highlight was the public release of Point Melt. Part of the company’s new EBMControl 6.4 software update, this novel process melts metal powder through small “points” instead of conventional lines.

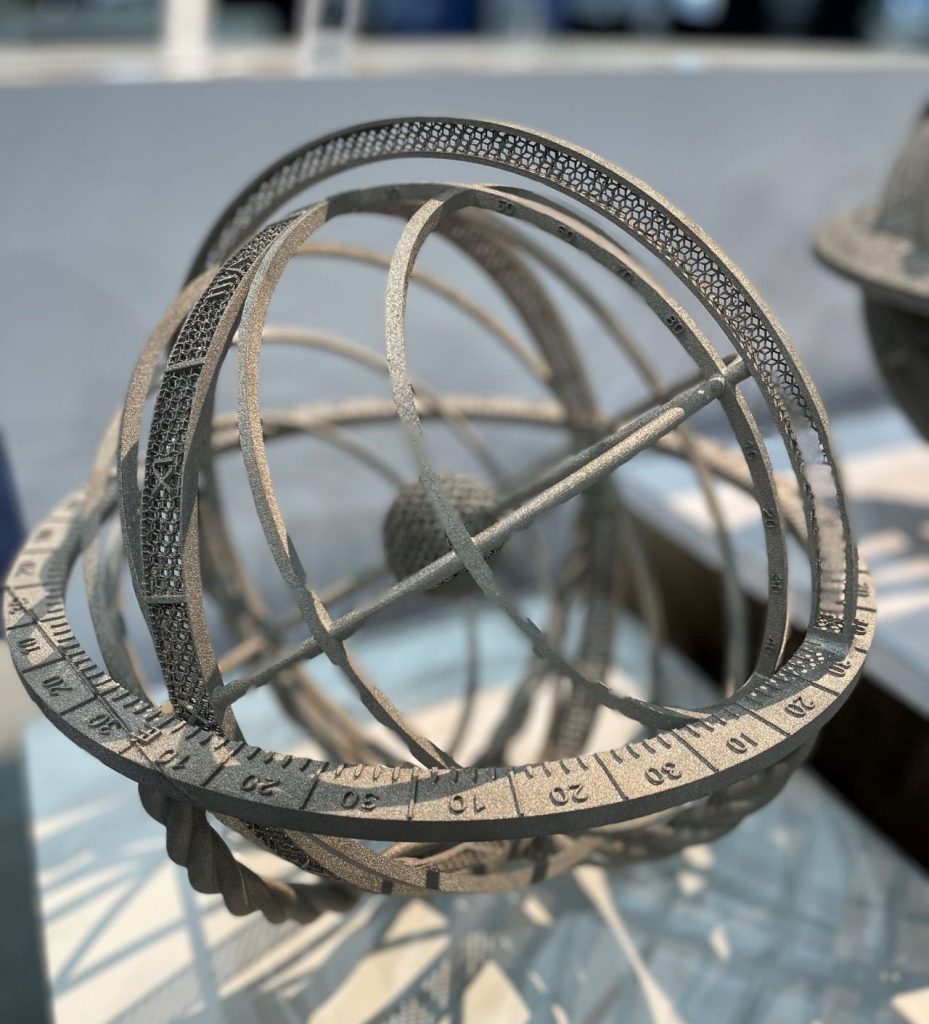

According to Schuppe, this improves melt pool control and surface finish. Point Melt also facilitates support-free 3D printing. At the Colibrium booth, Schuppe highlighted a 3D printed astrolabe that is “probably one of the first truly supportless parts made with powder bed technologies.”

He explained that the EBM process does not use support in the traditional sense of supporting the part as it is being 3D printed. “It’s more because of heat load,” or the amount of heat introduced to the powder bed. The support features visible on EBM parts are “heat stakes.” These act as “cooling fans”, deflecting the excessive heat often used to melt metal powder.

Colibrium’s new Point Melt technology can “more discreetly control the heat input,” and avoid overheating or over-penetration. According to Schuppe, this removes the need for “heat stakes,” and results in a more consistent surface finish in the final part.

As Point Melt is implemented via software, it requires no hardware changes for existing customers. Schuppe added that users can take a hybrid approach when using Point Melt. Sections that don’t require high precision can be 3D printed quickly with line melting, while Point Melt can be used for more critical areas requiring precise control and zero supports.

Schuppe emphasized this technology increases the affordability of EBM 3D printing. “Any part made with EBM today can be produced more economically with Point Melt,” he stated.

The first image shows an astrolabe printed without Point Melt, the second shows the same part 3D printed using Point Melt without supports. Photo via Colibrium Additive on LinkedIn.

The advantages of AM for aerospace and defense

Colibrium Additive recently completed a strategic rebranding from GE Additive to an independent company within the GE Aerospace group. Schuppe stated that the company’s ongoing relationship GE Aerospace offers significant benefits, particularly in 3D printing for aerospace applications.

He highlighted the synergy between the two organizations, noting that daily collaboration allows rapid problem-solving when designing aerospace components. One area of innovation is the development of heat exchangers for aircraft engines. These complex parts often pose challenges in CAD modeling and quality inspection.

Colibrium’s 3D printing technology reportedly streamlines this process by “completing the value chain.” Testing feedback can be efficiently integrated back into the CAD model. According to Schuppe, this reduces the number of iterations from ten to just two.

Schuppe added that the company’s role as an in-house 3D printing expert gives both Colibrium and GE Aerospace a unique advantage. “We’ve developed a lot of technology that specifically addressed their needs,” he explained. “In some cases, we’ve taken that technology into the products we’re selling publicly. In other cases, we provide them with a differentiated product that no one else can offer.”

The Colibrium Additive CTO also shared insights into the company’s innovations within the defense sector. A major focus has been on sustainment, with Colibrium “working very closely” with the Department of Defense (DoD) to secure supply chains. In particular, the DoD is investigating the use of additive manufacturing to produce spare parts for old military vehicles, such as aircraft and tanks.

Schuppe highlighted Colibrium’s partnership with the U.S. Air Force (USAF) through the Pacer Edge program. This initiative seeks to accelerate 3D printing spare parts in the military to provide the USAF with a new method of sourcing out-of-production parts.

“Parts are flying in the U.S. Air Force today that are 3D printed replacements of conventional components,” explained Schuppe. This has allowed the Air Force to get fighter jets “back in the air.”

This capability is crucial, considering the high financial and strategic costs of having vital weapon systems idle due to missing components. “A $100 million-plus asset sitting on the ground because of a $10,000 part is a strange value-equation,” added Schuppe.

Overcoming barriers to 3D printer adoption

The aerospace and defense sectors are fraught with challenges. Among these, certification requirements are particularly daunting. Schuppe highlighted the importance of demonstrating consistent part quality and reliability to regulatory agencies like the Federal Aviation Administration (FAA).

Manufacturers must prove that metal 3D printing can deliver parts with the same dependability as traditionally manufactured components. Schuppe stated, “We strive for high-quality, highly repeatable, reliable machines that ensure consistent output.”

He explained that post-production inspection typically involves computed tomography (CT), akin to 3D X-ray scans used in medical imaging. However, Colibrium Additive is developing in-situ monitoring of parts during the 3D printing process “so you don’t have to go back and do CT, which is a big benefit.”

The integration of additive manufacturing in defense applications also faces design challenges. Schuppe pointed to a significant learning curve for design for additive manufacturing (DfAM). “I still get a lot of people that come to me with designs from a 50-year-old casting, asking us to print them,” he explained. “They’re wasting their time if they don’t design specifically for 3D printing”

The future of AM and the 3D printing “laser wars”

Schuppe underscored Colibrium’s commitment to consistency and quality. The company hopes to increase 3D printer adoption, scaling applications into higher production volumes.

A notable trend in 3D printing is the race to increase the number of lasers in 3D printers to boost productivity. Over the past year, Chinese manufacturers like Xi’an Bright Laser Technologies and Farsoon Technologies have been competing to equip their laser powder bed fusion systems with up to 20 lasers. Earlier this year, Eplus3D took this a step further by launching the EP-M2050 – a large-format metal 3D printer with up to 64 lasers.

In Q2 2023, market intelligence firm CONTEXT predicted these 3D printer “laser wars” would drive 15% full-year revenue growth for the industrial metal 3D printer space.

However, Schuppe advocates for a more pragmatic approach, cautioning against the diminishing return of adding more lasers. “When you go from one laser to two lasers, you see a big benefit in terms of productivity. Going from two to four, you see some benefit, but it’s a diminishing return,” the Colibrium CTO argued.

He pointed to the negative cost and temperature impacts of adding more lasers to the 3D printing processes. For 3D printers with over 30 lasers, Schuppe argues that each laser is underutilized 90% of the time while incurring 100% of the costs.

Instead, Colibrium Additive will focus on achieving a “reasonable level of productivity without sacrificing quality.”

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows an astrolabe 3D printed using Point Melt without supports. Photo by 3D Printing Industry.