US based sporting equipment manufacturer Wilson Sporting Goods are leveraging 3D printing technology from Nexa3D, a high-speed resin 3D printer manufacturer.

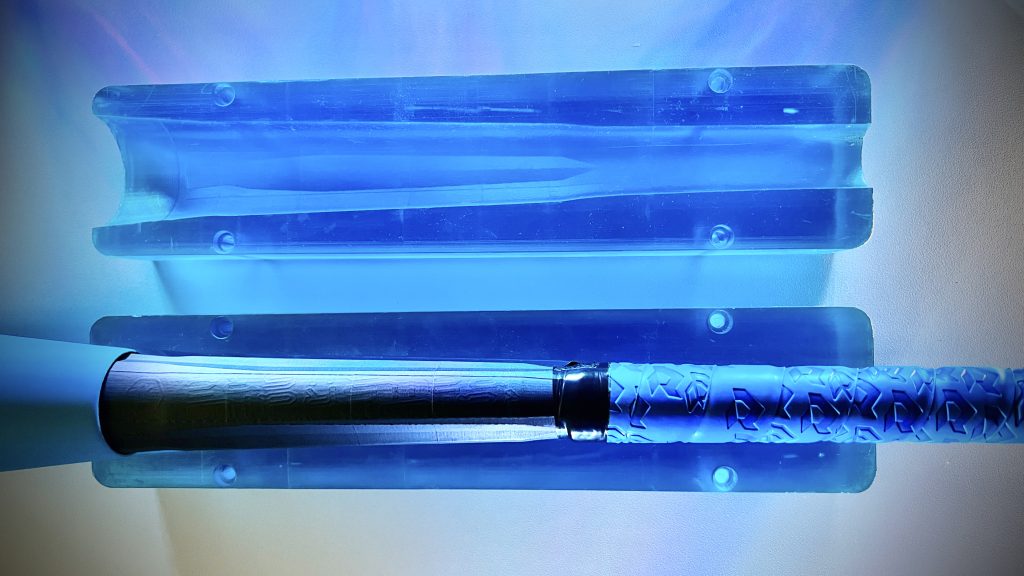

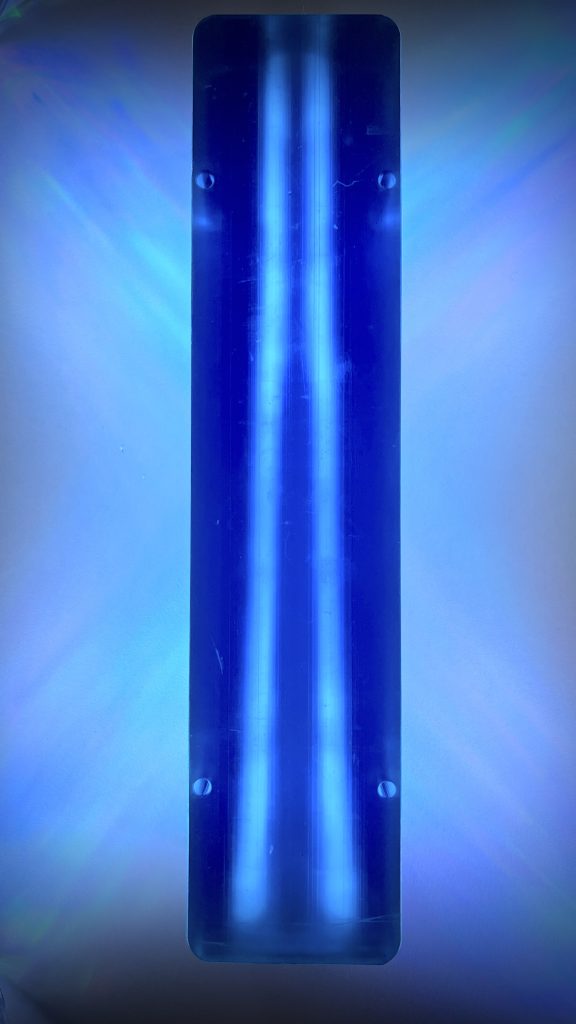

Nexa3D’s NXE400 printers are being used in combination with Addifab’s freeform injection molding (FIM) technology and xMOLD soluble resin, to prototype injection mold tooling for Wilson’s youth baseball bat grips. Nexa3D acquired Addifab in March of this year.

This collaboration between Nexa and Wilson is said to offer increased design freedom, substantial time savings, and greater R&D flexibility.

3D Printing Industry recently spoke with Lasse Staal, Director of Business Development at Nexa3D, and Wilson’s Director of Advanced Manufacturing Glen Mason, to learn more about this project, and the role 3D printing plays within the consumer goods industry.

3D printing and Wilson’s workflow

Incorporating Nexa’s 3D printing technology into Wilson’s prototyping workflow has significantly streamlined the R&D process.

“Traditionally, we have a subtractive model. We design, design for manufacture, do the tooling design, cut tooling, and then eventually mold parts,” explains Mason. “In this case, we’re working from the part design and we can bypass the design for manufacturing and mold design steps.”

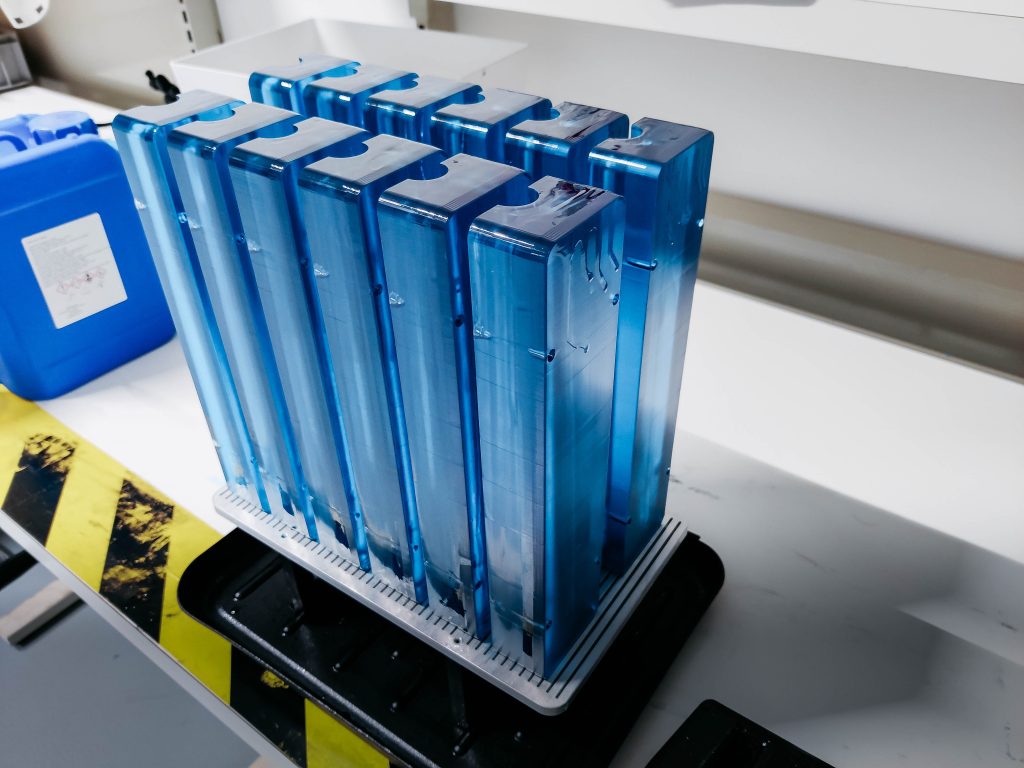

Once the prototype part has been designed, the mold is 3D printed using Nexa3D’s Lubricant Sublayer Photo-curing (LSPc) process. Here, multiple prototype tools can be produced in a single 3D print, with one example test run collectively 3D printing 6 different molds (12 pieces) in 9 hours. The part is then injection molded, followed by post-processing using Addifabs curing system and dissolvable resin.

The benefits of additive manufacturing

3D Printing offers substantial time savings within the prototyping process, thanks to the speed and quantity at which the molds can be 3D printed.

“It’s a much faster, much simpler way to get to part,” comments Mason. Indeed, Mason claims that “conservatively we’d see at least a 6x improvement between the time it takes to get a prototype in a traditional world, and the time it takes to get a prototype in an additive world.”

Additionally, the direct cost savings are also notable, with “the raw material and labor inputs going down in an order of magnitude of 10.” According to Mason, a part that would have cost $4,000 or $5,000 previously, can now be additively manufactured for $500.

These benefits are key to allowing Wilson to test more ideas, without worrying about the cost implications of a failed iteration. When using traditional manufacturing methods, Mason explains how the company would often commit a “tremendous amount of resources, and if we’re wrong it’s really expensive to change.”

3D printing allows Wilson to “fail fast and learn faster”, according to Staal. “In the economy of today, that learning is really a key currency because if you learn faster than your competition, you get ahead by a factor of many.”

Ultimately, 3D printing removes the limitations which would have traditionally prevented a number of projects from getting off the ground.

“When you look at all the projects globally, what this is really doing is enabling people to do things that would not happen in any other world because there just isn’t enough capacity. It’s hard to put a price on that” states Mason. Mason views 3D printing as an “enabling technology more than a cost reduction technology.”

Scaling and the prototyping process

Mason highlights that this process for 3D printing tooling is not scalable in the traditional sense of mass production. “I don’t visualize a scenario where we’re making 1000s of parts using this technology.” This is mainly due to raw material costs associated with this method of tooling.

However, when it comes to the “information part of the puzzle,” Mason sees great scaling potential. This is associated less with the prototype part itself, and more with the process for 3D printing those prototypes. “What this technology allows me to do is create a prototype part and at the same time, create a prototype process,” explains Mason. “So I’m creating the part in the same process that I would go to scale with.”

Similarly, Staal claims that the concept of scalability takes on a slightly different meaning when considering injection molding tooling. Whilst conventional injection molding is quite binary in nature, Staal points to 3D printing as providing the opportunity “to move into scale at a pace that is a little less of a leap of faith,” and ultimately achieving the “right level of productivity for each step of your product lifecycle at the lowest possible costs.”

In relation to 3D printing and consumer goods more generally, both Mason and Staal view mass customization as being key. Staal highlights the personalized hearing aid and dental aligner industries as incorporating additive manufacturing to achieve million part production runs. Staal states that millions of hearing aid shells are produced a year, with tens of thousands of 3D printers running in parallel.

Staal also highlights Nexa3D’s wide material compatibility as scaling high volume production runs. “You need to be able to make as many things as possible with one manufacturing setup,” claims Staal. With over 30 compatible materials, Nexa3D also offers an open materials program, which allows for the use of non-Nexa3D developed material.

As a result, on any given day, Nexa3D 3D printers can participate in multiple different production runs and different production lines. “Instead of having one machine doing one specific job all day long, one machine can contribute to the manufacturing of a lot of different products,” offering significant potential for scalability, Staal claims.

The future of 3D printing for consumer goods

What’s next for additive manufacturing and the consumer products industry?

Mason argues that there are still a number of challenges 3D printing needs to overcome before the technology moves beyond prototyping, and we see mass-produced 3D printed parts in the consumer’s hands.

“There’s challenges around printing parts from a material standpoint, from a surface finish standpoint, and even something as trivial as color is complicated.” The fact that additive manufacturing primarily produces mono-material objects is something which Mason views as limiting growth of 3D printing within this industry. “Until we can get multiple materials interacting at the same time, I don’t foresee 3D printing solving any consumer projects,” claims Mason.

Mason does envisage significant developments in speed and 3D print size. However, within the consumer goods sector, 3D printing seems set to compliment legacy technologies such as injection molding, rather than superseding them.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows Nexa3D 3D printed mold inserts. Photo via Nexa3D.