Established in 2017, Boston’s Digital Factory Conference and the Formlabs User Summit have grown into a greater platform for innovators. Bringing together leading end users from a variety of different sectors, these events discuss how 3D printing impacts business. On day one, we heard from Align Technology, FedEx, Desktop Metal, and Spirit AeroSystems about the various ways digitization is integrated within manufacturing.

Now, in highlights from day two of the Formlabs User Summit, we learn how Boston-based giants Gillette and New Balance are implementing additive manufacturing to improve consumer products. “Formlabs 3D printers began from myself and others recognizing a lack of certain products on the market,” commented Maxim Lobovsky, CEO of Formlabs.

“Gillette and New Balance are also understanding that there is a gap to build new consumer products in their respective industries – and 3D printing is the avenue to produce those ideas.”

Personalization over perfection

Last year, Gillette and Formlabs partnered to launch the Razor Maker™ project, providing consumers with custom 3D printed razor handles. Speaking on this partnership Donato Diez, Global Brand Manager for Gillette, explained how the technology is helping the company create something new and exciting for its customers.

“3D printing allows us to do things that are impossible and that helps us be more appealing or sexy to our customers,” Diez said. “In terms of brand building and storytelling, we can talk about razors in ways we previously did not imagine.”

Being able to create something new, and adaptable was also of great importance through the project, as Diez added, “We are in a world where the retail is changing as we speak. To keep up with this game we need speed, hence the beauty of additive manufacturing.”

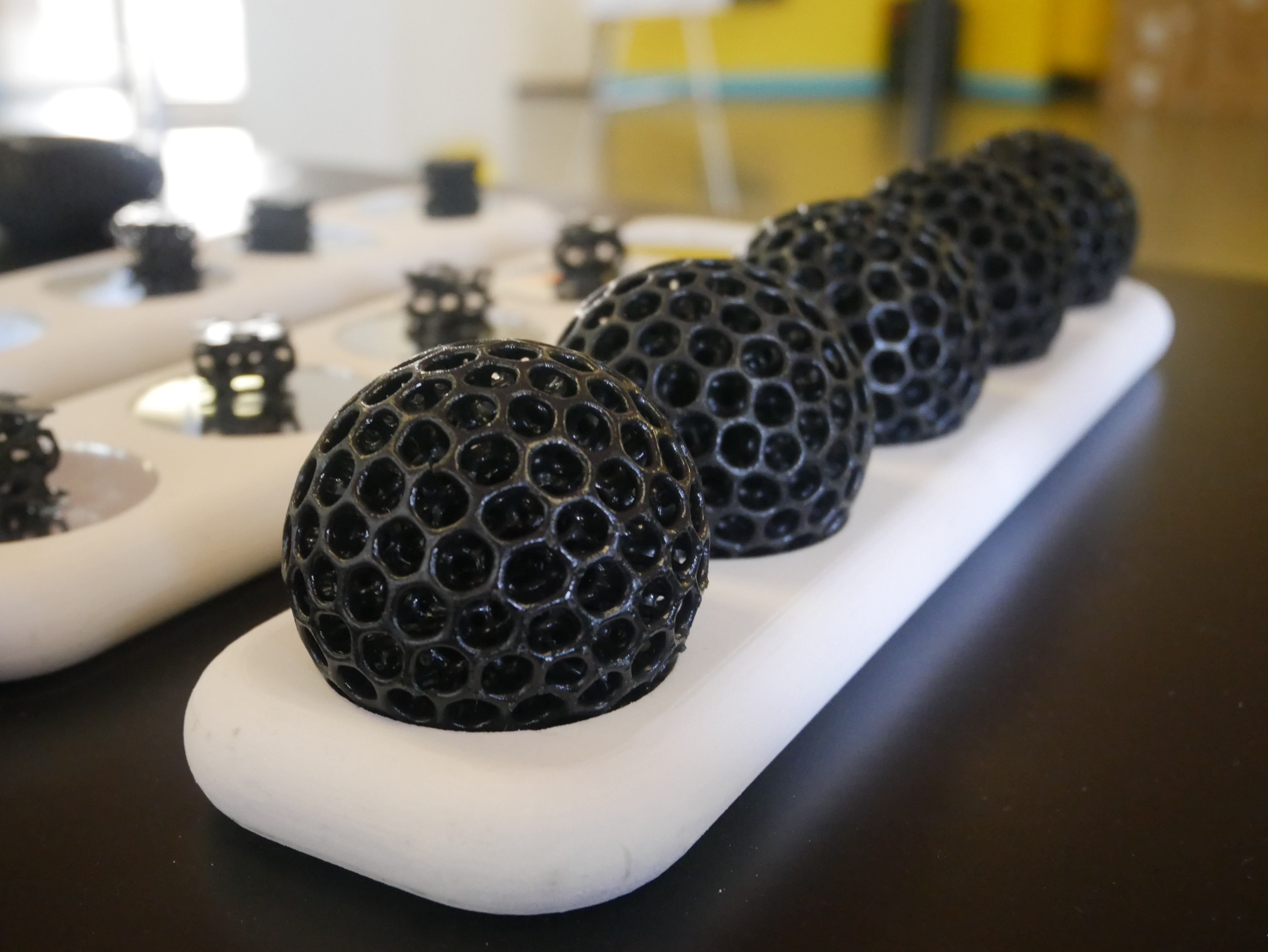

In the Razor Maker project, customers could choose the shape and of their razors from a selection of pre-made and geometrically complex designs. They could also add personalized text (i.e. a name) to the handle and pick which head would fit on the end. Once selected, the razors were made by Formlabs and shopped for free anywhere in the U.S. But this process has not always been plain sailing. As Diez continued, “I remember how many times we postponed the release of Razor Maker. In our eyes, some things in the campaign weren’t perfect.”

However, “Our team had to realize that the moment the consumers can tell you what your products can look like – is the chance you can meet their needs.”

Improving product performance

Around the time Formlabs announced its upcoming Fuse 1 3D printer the company also confirmed a new partnership footwear manufacturer New Balance. Working together to make suitable 3D printable materials for the “continuous production of shoes,” the first runs of footwear made in the collaboration was expected during 2018.

This week Katherine Petrecca, General Manager at New Balance Athletics, confirmed that they have now completed development of a new material to improve the performance of the New Balance shoe soles. Pointing out the high rivalry within this area, particularly where 3D printing partnerships are concerned, Petrecca commented “We’re in footwear, where everyone is competing with each other. This resin was formulated in an effort to increase the value in our products.”

The main goal of the material’s development was “to prove to the consumer that we can make 3D printed parts that are as good as or better than what they have now.” In this respect, Petrecca adds, “Materials development helped us focus on performance customization.”

Dan Dempsey, a Senior Additive Manufacturing engineer at New Balance, elaborated, “This resin was co-developed [over] 2 years with Formlabs for resilience and good impact properties for footwear. With AM you can vary a lot of the structure which allows us to engineer from the bottom to the top.”

Dempsey was also keen to point out the importance this advance within the 3D printing trifecta. “It all comes down to materials,” he stated, “You can have a million dollar 3D printer but if it can’t withstand your output it’s useless.”

“Materials such as this allow us to design the interior of a shoe rather than the just frame, which obviously leads to better customization and footwear capabilities.”

The New Balance Formlabs resin is currently used internally, though further developments on this partnership are expected in the months to come.

The 2019 Digital Factory Conference and the Formlabs User Summit has now come to a close, however 3D Printing Industry will be covering more current announcement at the RAPID + TCT Show later this month.

Subscribe to the 3D Printing Industry newsletter, follow us Facebook and like us on Twitter for to-the-minute events coverage and updates.

Voting is still open for the 2019 3D Printing Industry Awards.

Visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows Razors 3D printed by Formlabs for the Razor Maker project. Photo by Tia Vialva.