GE Research has partnered with binder jet 3D printer manufacturer Voxeljet as part of the U.S. Department of Energy‘s $14.9 million award.

The primary objective of this partnership is to advance the development and commercialization of a large sand binder jet 3D printer known as the Advanced Casting Cell (ACC). This effort plays a crucial role in expediting the transition to clean power in the United States. The ACC project involves a consortium of leading organizations, including Voxeljet, GE Hydro, GE Onshore Wind, GE Offshore Wind, Clemson University, Oak Ridge National Laboratory, and Hodge Foundry. Each of these partners brings their expertise to the table in pursuit of common objectives related to clean energy technology.

Enhancing wind and hydro energy production

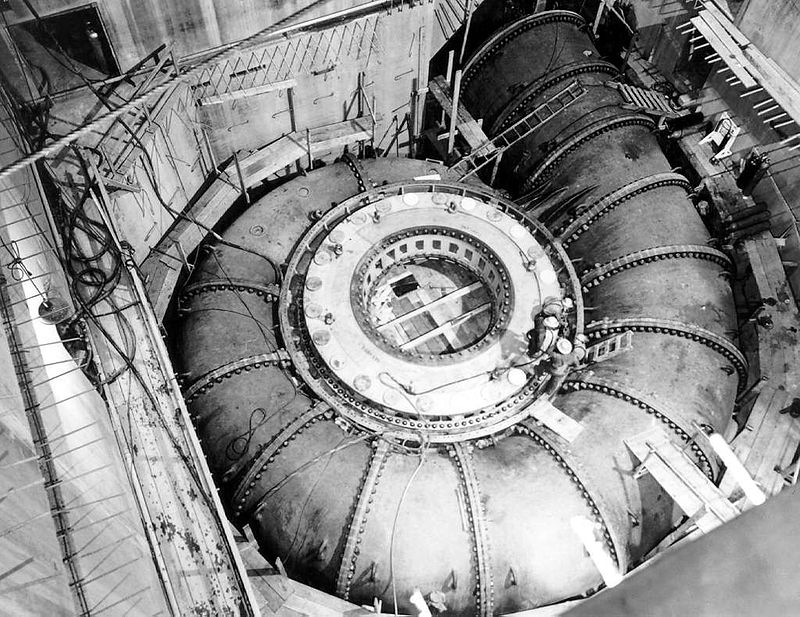

Voxeljet’s ACC sand binder jet 3D printer is at the core of its partnership with GE Research. The ACC is designed for the efficient production of large sand-casting molds, especially crucial for the growing wind and hydro energy sectors. Notably, the 3D printer can create molds for massive parts, ranging from 10 to 60 tons. Weighing over 60 metric tons, the GE Haliade-X Offshore Turbine‘s nacelle instantly benefits from this technology. The ACC’s potential to significantly reduce production time for such critical components is a standout advantage, promising shorter production durations and cost savings.

The primary goal of this leap in technology is to shorten the production time for patterns and molds from up to ten weeks to just two weeks. Moreover, this system is expected to reduce hydropower costs by 20% and cut lead times by four months. A key focus of the project is optimizing the production of a 16-ton rotor hub, a central component in wind turbines, which connects the blades to the shaft for energy conversion. The ACC streamlines the production of this substantial component.

Additionally, the project aims to develop a robotic welding process for assembling the Francis runner, a vital part of hydropower turbines that converts water energy into rotational motion. This runner weighs over 10 tons. To ensure the effective use of the ACC, a new training program is in development, educating local workers on the benefits of this 3D printing method.

Earlier this month, Voxeljet initiated a review of strategic alternatives, encompassing financial options, investments, mergers, joint ventures, and partnerships. The decision, led by the Management and Supervisory Boards, involves assistance from BNP Paribas Securities Corp. as financial adviser and Hogan Lovells International LLP as legal adviser.

Clean energy advancements

In alliance with start-up Dimensional Energy, Cornell University and Lithoz secured funding to develop advanced ceramics for 3D printing parts of clean energy reactors. With a $50,000 grant, the project aimed to create ceramics that can endure high temperatures within thermocatalytic reactors. Leveraging computer modeling and 3D printing, the team planned to craft structures designed to enhance durability and CO2 conversion rates, potentially advancing clean energy technology.

Stanford University researchers harnessed 3D printing to develop a device called Axially Graded Index Lens (AGILE) to enhance solar array efficiency without the need for tracking systems. AGILE’s tipless inverted pyramid design captures over 90% of incident light and triples its brightness. It can passively collect light from various angles. Using a special material created through 3D printing, the team developed mirrored devices to redirect misdirected light. AGILE could be integrated with regular solar panels to capture scattered light from Earth’s atmosphere, weather, and seasons, potentially making panels smaller, cheaper, and more effective while requiring the right material formulation, said the team.

Voting has now started for the 3D Printing Industry Awards 2023. Cast your vote now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Voxeljet’s company logo. Photo via Voxeljet.