FIT AG, a German additive manufacturing group, has recently announced the founding of its newest subsidiary, FIT Japan KK which aims to expand FIT AG’s operations and customer base within Asia’s developing additive manufacturing market.

Carl Fruth, CEO of FIT AG, comments, “We want to expand these business relationships as a technology leader for Japan as well as for the entire Asian region and fix them in the long term.”

Japan’s additive manufacturing climate

With development and distribution sites across the U.S., Romania, and Russia and over 20 years of experience, FIT AG is an expert in providing services in rapid prototyping and additive design manufacturing (ADM) technologies.

The ADM service package, which will soon enter Japan’s manufacturing market, includes a complete portfolio of additive manufacturing technologies starting from the pre-production phase to post-processing procedures, as well as quality assurance methods.

Despite its sales and project management operations in Nagoya, Japan, FIT AG has identified a lack of presence within the economy for additive manufacturing technologies. According to FIT AG as Japanese manufacturers, specifically large car manufacturers, integrate AM processes into their production of end-parts and tools, the demand for the relevant technologies increase.

“When I first heard about FIT AG and its ADM concept, I immediately recognized the potential that it contained,” said Yasushi Murata, FIT AG’s Japanese manufacturing industry expert.

Past production partnerships

Prior to this, FIT AG has expanded its operations through collaborations with manufacturers and construction companies working within the 3D printing industry.

In early 2017, global construction company, Caterpillar Inc, headquartered in Illinois, announced a three-year partnership with FIT AG. This partnership kick-started production of a range of 3D print aluminum and titanium parts for Caterpillar’s range of large-scale machinery.

Several months later, FIT AG revealed a strategic partnership with industrial 3D printer manufacturer EOS, which is supplying its five of its EOS 400M – 4 systems to create components for automotive, medical and aerospace sectors.

And, in Russia, FIT operates as one half of FITNIK. FIT AG’s other established subsidiaries include FIT Prototyping GmbH and FIT Production GmbH.

Never miss out on the latest in 3D printing by subscribing to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking for a new career? Sign up to 3D Printing Jobs to post and find new opportunities near you.

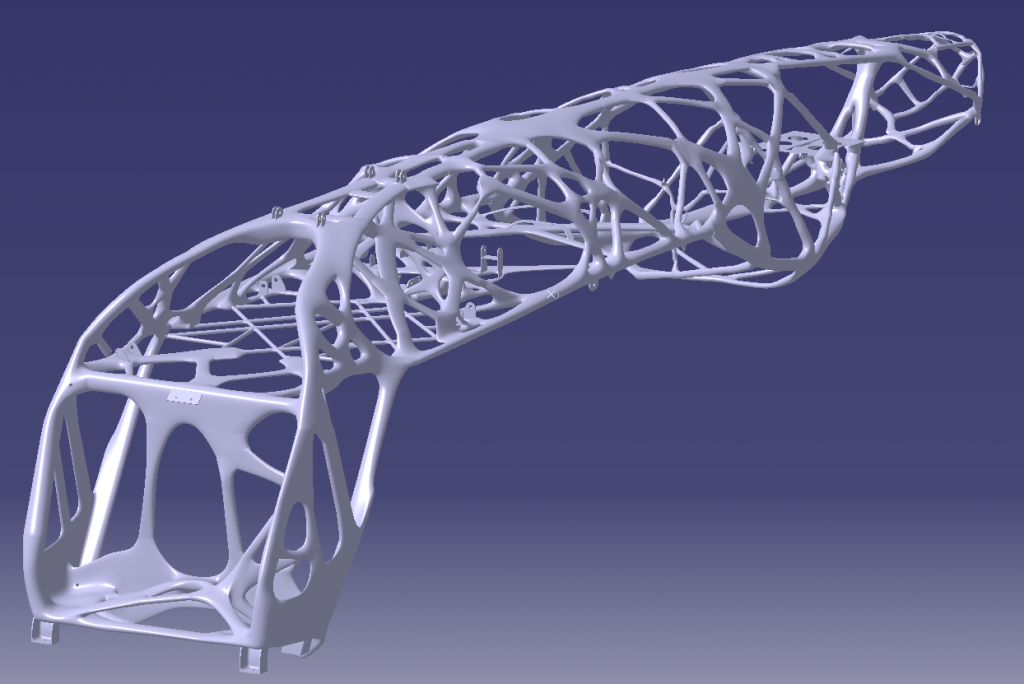

Featured image shows inside of FIT AF manufacturing facilities. Photo via FIT AG.