Fabbrix, a division of Crea3D, has debuted its new ELEMENTO V2 3D printer.

The large format FFF printer is aimed at professionals working in automotive, arts, architecture, and packaging. It features a set of dual extruders, automatic bed leveling, and a multitude of quality of life features wrapped up in an open materials philosophy. The system is the second iteration of the previously released ELEMENTO 3D printer, although the differences between the two are fairly nominal.

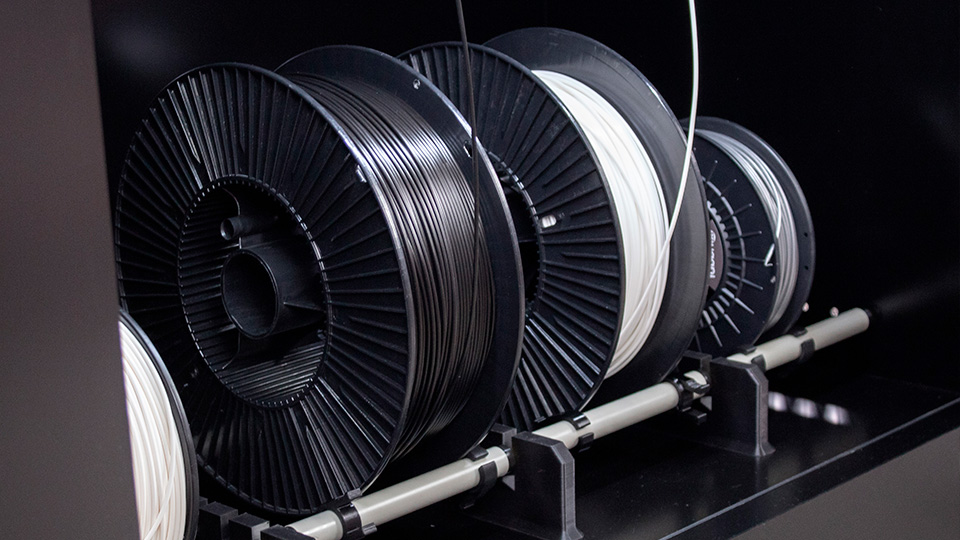

Fabbrix filaments

The Italian manufacturer is very much a newcomer to the 3D printer marketspace, as it has made a name for itself developing thermoplastic filaments up to this point. The materials range from basic polymers for general purposes to production-grade materials for specific, demanding applications.

Fabbrix offers filaments such as PPS for high-temperature components, PET for food and beverage containers, CNT for low-voltage electrical circuits, and even wood PLA for aesthetic display pieces. Customers can also opt for BVOH – a lesser known soluble support material that dissolves faster than PVA and doesn’t absorb as much ambient moisture.

The ELEMENTO V2

The ELEMENTO’s prime feature is its large-scale build volume, which stands at 1000 x 550 x 500mm. This much space enables the production of sizable professional parts while also giving users the option of high-throughput small part fabrication. Within the chamber is an aluminum/glass heated print bed and an auto-leveling sensor for ease of use.

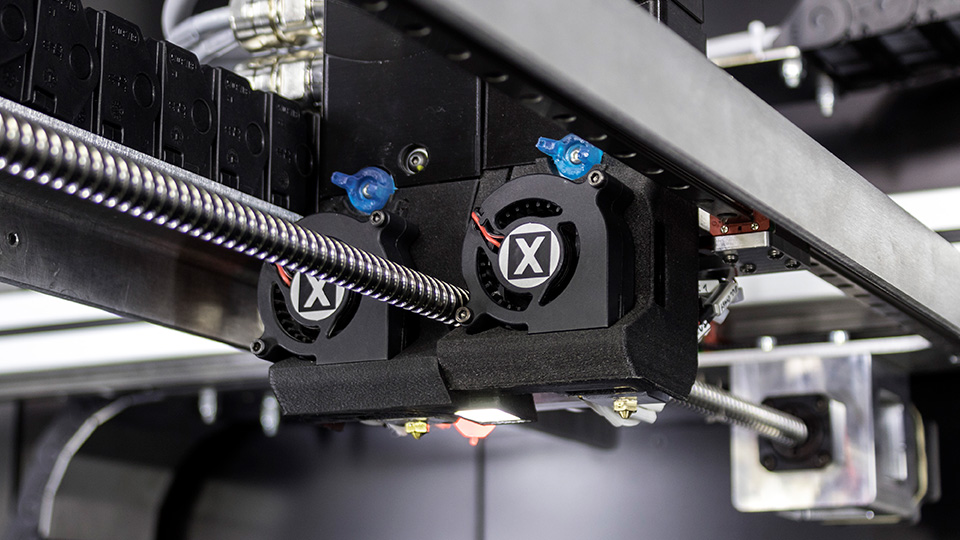

The dual extruders can be customized with five swappable nozzle sizes ranging from 0.6 – 2mm. All three axes are guided by linear rails with ball bearing screws for smoother movement and cleaner print surfaces.

Coming from a materials background, Fabbrix prides itself on its open materials system, meaning the ELEMENTO is compatible with a vast range of thermoplastic filaments. The full Fabbrix range is, of course, usable and optimized but third party materials are also encouraged. The printer is even compatible with certain specialist materials such as carbon-reinforced nylon.

Technical specifications and pricing

Below are the technical specifications for the Fabbrix ELEMENTO V2. The machine is available to pre-order now and customers that are interested should visit the Fabbrix website to receive a quote.

| Printhead | Double direct extruder |

| Filament diameter | 2.85 mm |

| Layer resolution | 0.6 mm nozzle: 300 – 100 micron |

| 0.8 mm nozzle: 400 – 150 micron | |

| 1 mm nozzle: 500 – 300 micron | |

| 1.2 mm nozzle: 600 – 350 micron | |

| 2 mm nozzle: 1000 – 600 micron | |

| XYZ resolution | Up to 2.5 micron |

| Build volume | 1000 x 550 x 500 mm |

| Build speed | 150 mm/s |

| Build plate temperature | 20 – 80°C |

| Nozzle temperature | 180 – 300°C |

| Connectivity | Wi-Fi, LAN, USB |

| Interface | Touchscreen + Fail Safe |

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ELEMENTO 3D printer. Photo via Fabbrix.