Engineers at the US-based California State University, Los Angeles and Turkish Eskisehir Osmangazi University have developed a low-cost wire arc additive manufacturing (WAAM) 3D printer that can be built for just $1,000.

By integrating gas tungsten arc welding (GTAW) technology into an FDM-like gantry setup, the researchers have been able to create a machine that doesn’t rely on complex robotic arms, allowing them to keep it affordable and open-source, while initial testing has revealed its compatibility with both carbon steel and Inconel 718.

“The proposed system, together with proper process parameters, can be used with many metallic alloys that can be processed by GTAW and WAAM, with less effort and lower cost compared to the expensive powder bed systems,” said the team in their paper. “Some examples of the alloys that can be processed include titanium, aluminum, nickel and cobalt-based superalloys, and low-alloy steels.”

Adopting Gas Tungsten Arc Welding

Particularly in the aerospace and automotive sectors, metal 3D printing technologies such as powder bed fusion (PBF) and direct energy deposition (DED), are beginning to demonstrate significant advantages over conventional subtractive processes. Using PBF, for instance, it’s now possible to produce intricate objects with internal passages and high-res features, however the researchers say that such systems also tend to be expensive and complicated to operate.

Likewise, the engineers acknowledge the large build volumes and component repair capabilities associated with DED machines, but maintain that the technology relies on costly lasers and robotics, and resulting parts need extensive post-processing.

Of the conventional metal 3D printing processes out there, the team reserves particular praise for GTAW, an approach in which an electric arc is used to melt wire feedstock into desired shapes in an inert atmosphere. When used within an AM system the technology is harnessed in the DED technology category, such setups have become popular in research circles due to their affordable semi-automatic wire feed systems, and broad alloy compatibility.

Yet, despite these benefits, developing an effective low-cost GTAW AM system can be a perilous task, in which the use of unstable parameters can lead to the creation of defective parts or cause safety complications. Undeterred, the US-Turkish team has now come up with a novel way of driving down the cost of WAAM machines, by building one in a 3-axis configuration, and set about testing its efficacy.

WAAM 3D printing for the people

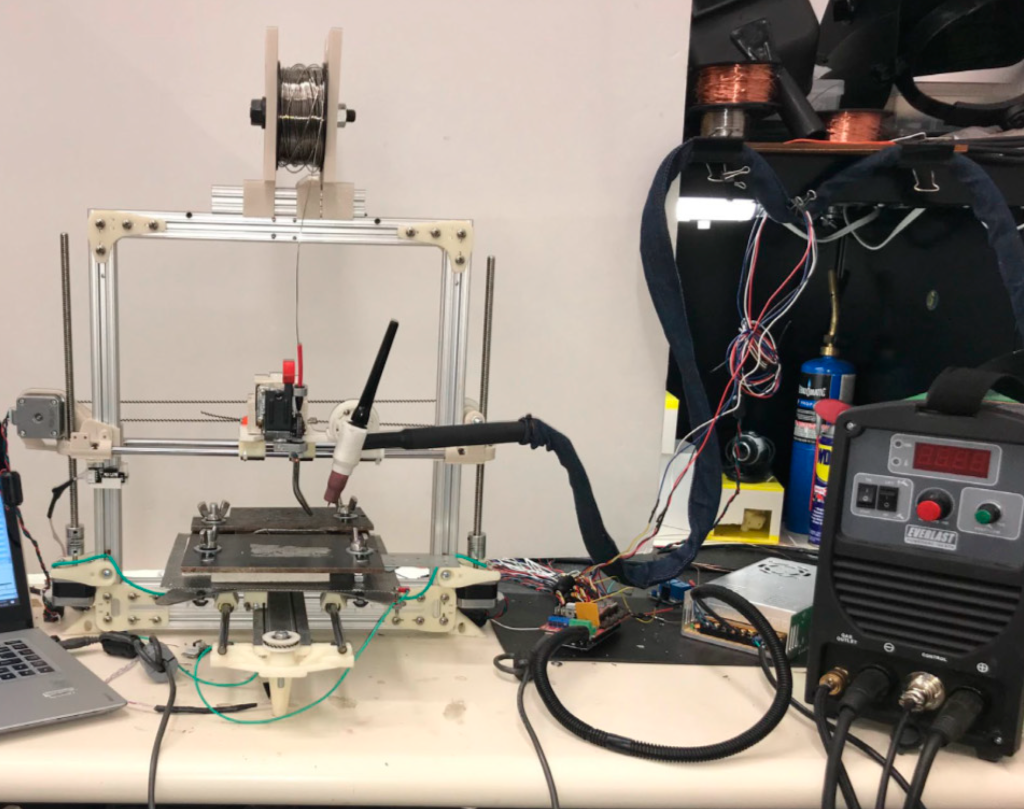

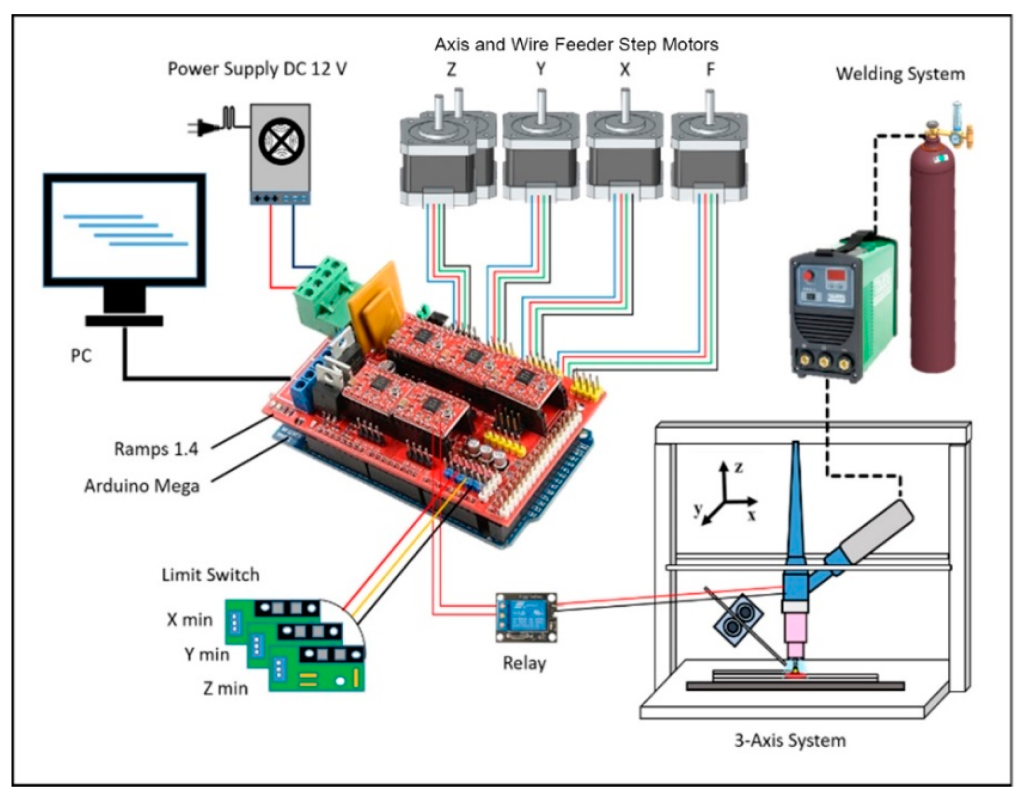

Composed of a microcontroller, TIG welder and specially designed parts such as a custom automatic feeder on an outer frame, the appearance of the team’s GTAW system resembles that of many commercial Cartesian FDM 3D printers. However, rather than being buying the device’s mount, the team actually machined it from scratch, holding it together with over forty ABS parts produced via a Stratasys U-plus machine.

In doing so, the researchers found that they were able to keep the cost of their build down to around $1,000, excluding the gas container and computer used to sustain and program it. Once they’d built their prototype, the team went on to subject it to testing, in which it proved capable of receiving instruction from an open-source Arduino microcontroller, and creating a tungsten arc with a current of 5-150 amps.

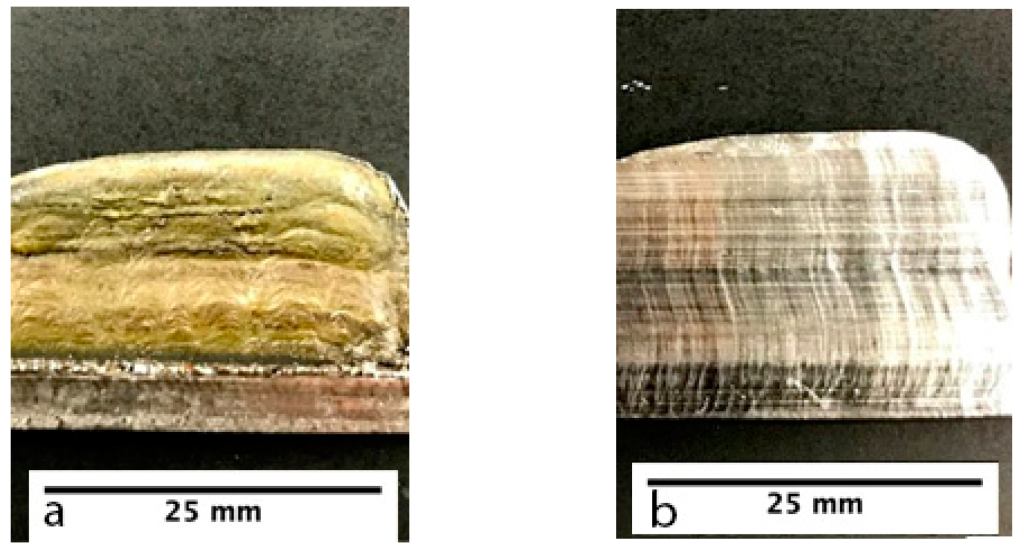

However, the GTAW AM system also experienced various teething problems, such as part softening, surface waviness and shape tapering due to feed rate fluctuations and torch overheating. Although the team has introduced several fixes to address these issues, they admit that the angle between torch, layer and wire feeder still needs to be adjusted constantly, while misshapen parts remain an issue.

Moving forwards, the engineers say that some of their machine’s problems can be overcome by fitting it with an additional inert gas-filled shielding chamber that prevents metals from being atmospherically interfered with, and given that it can be run automatically, they maintain it can be made safe-to-operate for everyday users too, despite the extremely bright and hot arc generated during production.

“In this study, we designed a low-cost wire-arc additive manufacturing system that offers an alternative solution to develop and repair high-value metallic components,” concluded the team in their paper. “The [machine’s] applications include the repair and manufacture of parts such as fittings, implants and heat exchangers in the aviation, automobile and medical industries.”

WAAM’s heavy-duty applications

Over the last two years, WAAM’s ability to 3D print ultra-robust parts has increasingly been put to the test within maritime, defense and experimental infrastructure applications. Late last year, robotic metal 3D printing firm MX3D revealed that it had used the technology to create a unique ‘skeletal floor’ for a prototype European Space Agency lunar settlement.

Just before MX3D’s WAAM excursion, heavy equipment manufacturer Huisman also announced that it had deployed the technology to 3D print four crane hooks. Measuring 1.7 x 1.3 meters across, and weighing in at a hefty 1,700 kg, each of the large-format prints is capable of lifting up to 350 metric tons in weight.

Similarly, in other maritime applications, WAAM has been used by the likes of the French firm Naval Group, to manufacture a hollow propeller blade demonstrator. Built from stainless steel in less than 100 hours, the 300 kg print was successfully tested against fatigue and corrosion, with its hydrodynamic properties also being assessed via numerical simulation.

The researchers’ findings are detailed in their paper titled “Development of a Low-Cost Wire Arc Additive Manufacturing System,” which was co-authored by Miguel Navarro, Amer Matar, Seyid Fehmi Diltemiz and Mohsen Eshraghi.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the researchers’ prototype gantry-mounted WAAM 3D printer. Photo via the Journal of Manufacturing and Materials Processing.