Dutch Superbike manufacturer Electric Superbike Twente have collaborated with K3D, a 3D metal printing company, to produce a new cooling shell for its electric bike motors.

This will be the first 3D metal printed component used by Electric Superbike Twente and paves the way for the adoption of additive technologies across the electric superbike racing industry.

The collaboration began shortly after Electric Superbike Twente encountered a problem while designing its second electric motorbike. The team realized that the manufacturing techniques they were using to produce the cooling shell were inadequate for a high performance motorbike.

The limitations of traditional manufacturing

Feitse Krekt, Technical Manager of this years Electric Superbike Twente team commented on the teams difficulties, “The cooling shell of the first superbike consist of multiple parts, which were quite hard to produce, using conventional production methods like turning and milling. For these production methods, lots of material was needed and therefore the end product turned out to be quite heavy,”

He added, “Because of the turning process, the wall thickness needed to be higher than optimal, and we were unable to cool the electric motor as efficient as possible. Therefore we had less power than desired and sometimes needed to slow down to not overheat the electric motor.”

As a result of these issues the superbike decided to contact K3D, part of the Kaak Group, who specializes in metal 3D printing. K3D was the first company in the Netherlands to acquire a MetalFab1 3D metal printer from Additive Industries, with which it has produced over 35,000 products since 2016.

The decision to use K3D to produce this part gave them a freedom of design that traditional manufacturing techniques cannot provide, as Jaap Bulsink, CTO of K3D explains, “The part has an optimal cooling performance due to the thin walled design with internal channels on the right spot. This was only possible with 3D metal printing where you have optimal freedom of design. On top of this the part had been designed for minimal weight. The part was printed first time right and is very accurate and can be used directly without any postprocessing.”

This is not the first time 3D printing has been employed in the manufacture of electric motorbikes. BigRep, based in Germany, has created a fully functional 3D printed electric motorbike, however the bike was only made for design exploration purposes and is currently not a viable commercial product. Elsewhere in motorbike design, earlier this year BMW unveiled its 3D printed a concept frame for the BMW S1000RR sports bike. It’s unlikely that this bike will ever see shelves though either.

Electric Superbike Twente is currently in the process of assembling its bike, after which it will be tested and finally revealed on the 24th of May 2019, at the Kinepolis in Enschede, Netherlands.

You can now cast your vote for the third annual 3D Printing Industry Awards. Help decide this year’s winners now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook. Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

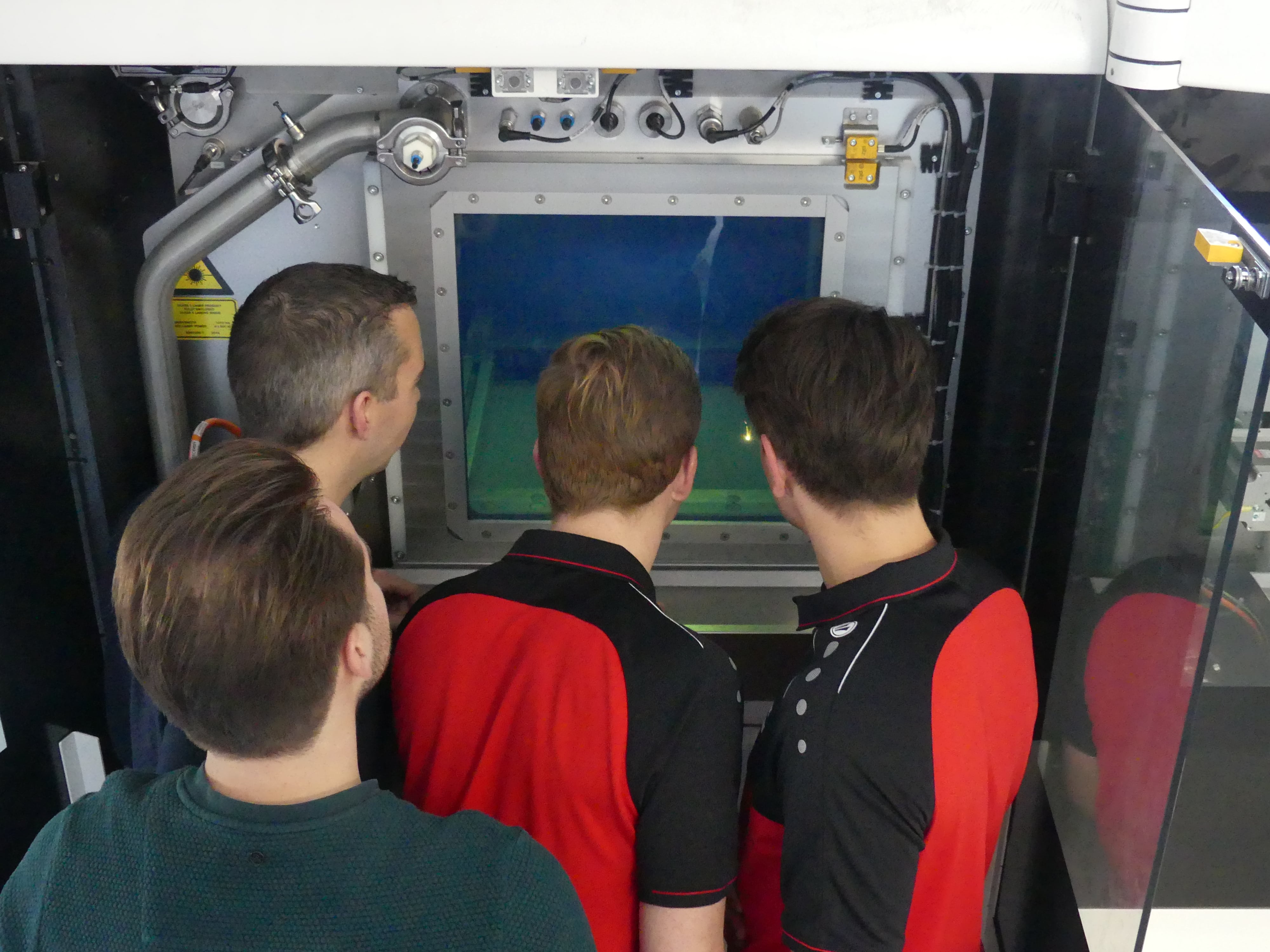

Featured image shows a Liion-GP electric motorbike, the fist one created by Electric Superbike Twente. Image via Electric Superbike Twente.