High-precision SLA 3D printer producer DWS is expanding its existing portfolio with a new line of automated systems. Named XCELL 3D, the 900 x 1400 mm machines integrate cleaning and curing into a single workflow, reducing time wasted in manual post processing.

Auto wash and cure

After printing in an XCELL 3D, the build plate elevates and moves objects into a second chamber for washing. In the next step, the plate dips the objects into a third chamber where they are cured to remove any residue.

The out-of-the-printer result is a plate containing fully cured objects, ready for support removal and use in a chosen application.

Further pushing automation, a noticeable trend in the industry, material management inside the XCELL is handled by DWS’ XPOD concept. Enhancing existing material cartridges, the XPOD is capable of extracting unused photopolymer resin from the bed to be recycled in the next print job.

Technical specifications

DWS’ expertise is in applications that require an exceptional level of detail. As such, the XCELL 3D is available in three models: the 6000SD for industrial prototyping and jewelry making, the 6000HD for finer filigree, and the 6000PD which is suitable for dental applications.

The main difference between the machines is max resolution, which has mechanical values ranging between 10 and 100 μm dependent on material used. All XCELL 3D printers have a build envelope of 200 x 150 x 200 mm.

Coming soon from DWS

XCELL 3D printers will be available to buyers in 2018 alongside a new, large format, large format XPRO S machine, and expansion of the desktop XFAB range.

According to Maurizio Costabeber, General Manager of DWS, “This is a very exciting and defining moment for our company,”

“For over two decades we have been pioneering and disrupting segments of industry with our innovative stereolithography systems and materials to the benefit of our customers,”

“Today we are taking bold steps to make additive manufacturing 4.0 real and affordable through our ground-breaking new products and our significantly expanding global presence.”

For all the latest 3D printer releases and news subscribe, like and follow here.

Register for 3D printing jobs.

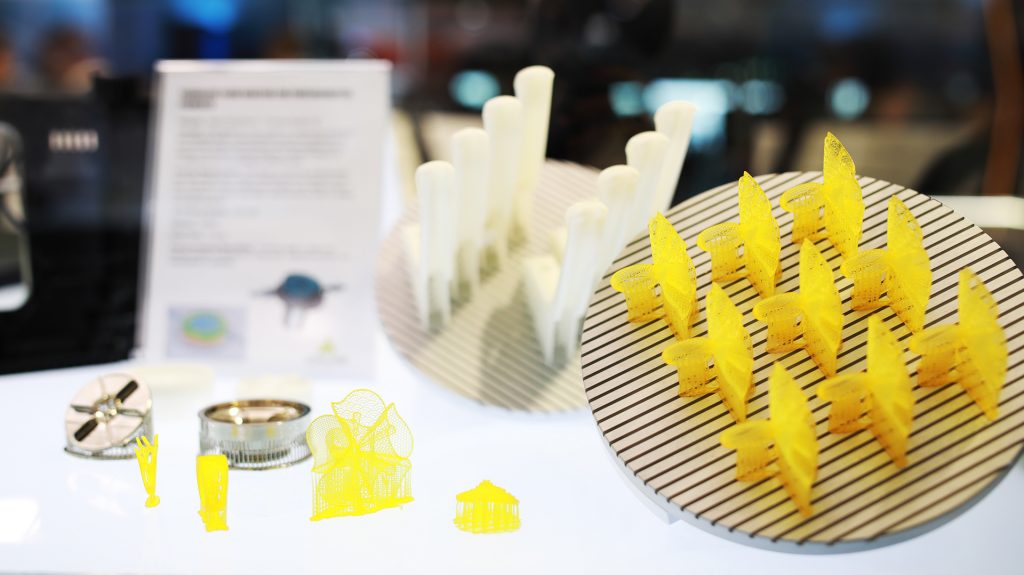

Featured image shows an XCELL 3D printer. Photo via DWS