Nominations are now open for the 3D Printing Industry Awards 2023. Who are the leaders in 3D printing? Find out on November 30th when the winners across twenty categories will be announced during our London-based live awards ceremony.

QIDI Tech, a Chinese 3D printer company specializing in all-in-one FDM 3D printer R&D and production, has unveiled their new X-PLUS3 and X-MAX3 3D printers. With ultra-fast 3D print speeds and substantial build volumes, these new offerings mark the latest additions to QIDI Tech’s growing FDM portfolio.

Founded in 2014, QIDI Tech produces 50,000 FDM 3D printers annually out of its 15,000 square meter production workshop, and 1,000 square meter R&D center. Priding itself on its professional R&D team, QIDI also offers a quick after-sales service through its dedicated after-sales team.

With rich experience in OEM and ODM, QIDI owns a number of patents and software copyrights. All QIDI products possess MET safety quality certification, and CF, FCC and ROHS certifications. Moreover, as the first Chinese 3D printer supplier to partner with Amazon directly, QIDI Tech boasts strong international cooperation experience. Alongside Amazon, QIDI also has a long-term strategic partnership with WalMart.

The X-PLUS3 stands out as a high-speed, cost-effective commercial-grade 3D printer, and is said to be the only 3D printer with a constant temperature chamber within the $1000 price range. Additionally, the QIDI X-MAX3 industrial 3D printer offers one of the largest 3D print volumes of all competing high-speed 3D printers.

Black Friday Discounts Now available

For Black Friday, the company is offering discounts on 3D printers, filament, and more.

The QIDI X-MAX 3 is available at a discount of €100, while the QIDI X-PLUS 3 has a similar saving. In addition, savings of up to 35% are available on filament. Click here for the Black Friday 3D printing material savings.

QIDI also has a range of special prices which can be found on the QIDI Tech Black Friday sales page.

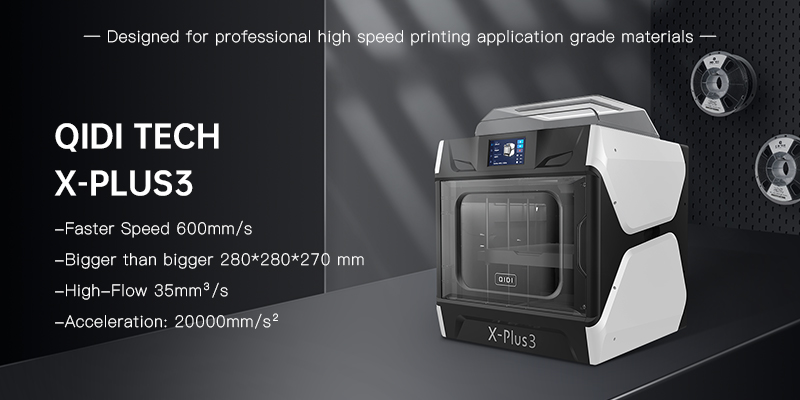

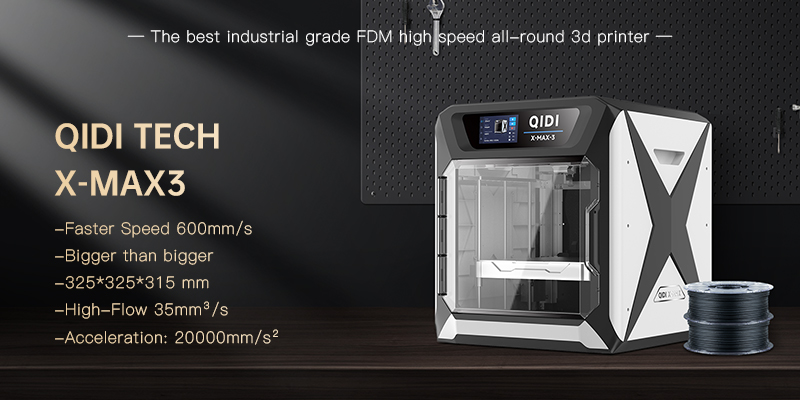

The new X-PLUS3 and X-MAX3 from QIDI Tech. Images via QIDI Tech.

Ultra-fast 3D printing

Key to both of QIDI’s new FDM 3D printers is their ultra-fast 3D printing speeds. The MAX3 and PLUS3 models both offer speeds of up to 600 mm/s, and impressive maximum acceleration of 20,000mm/s². These ultra-fast speeds increase productivity, production efficiency and time savings. Moreover, less overall usage time reduces the environmental impact of the 3D printers. QIDI recommends that, when conducting high-speed 3D prints, users should use a copper alloy nozzle for optimal results.

How do the QIDI X-MAX3 and X-PLUS3 achieve these impressive 3D printing speeds? One key factor is their CoreXY Structure, which both reduces motion inertia and increases motion speed. The CoreXY architecture also includes a TMC2209 silent drive, significantly reducing noise during high-speed 3D printing.

QIDI Tech has also incorporated a lightweight high-grade hardness steel linear hollow optical axis into both 3D printers. This addition allows both the X-MAX3 and X-PLUS3 to move faster without risking any 3D print quality degradation, improving surface straightness and ensuring 60% lower error deflection. What’s more, this system is highly durable, and does not require frequent maintenance. The optical axis typically lasts a lifetime without needing to be replaced.

Both 3D printers also include a new all-metal, ultra-stable frame. Reinforced with metal cross-beams at the bottom, and resistant to deformation, this new structure adds greater stability whilst also enhancing the aesthetics of the product.

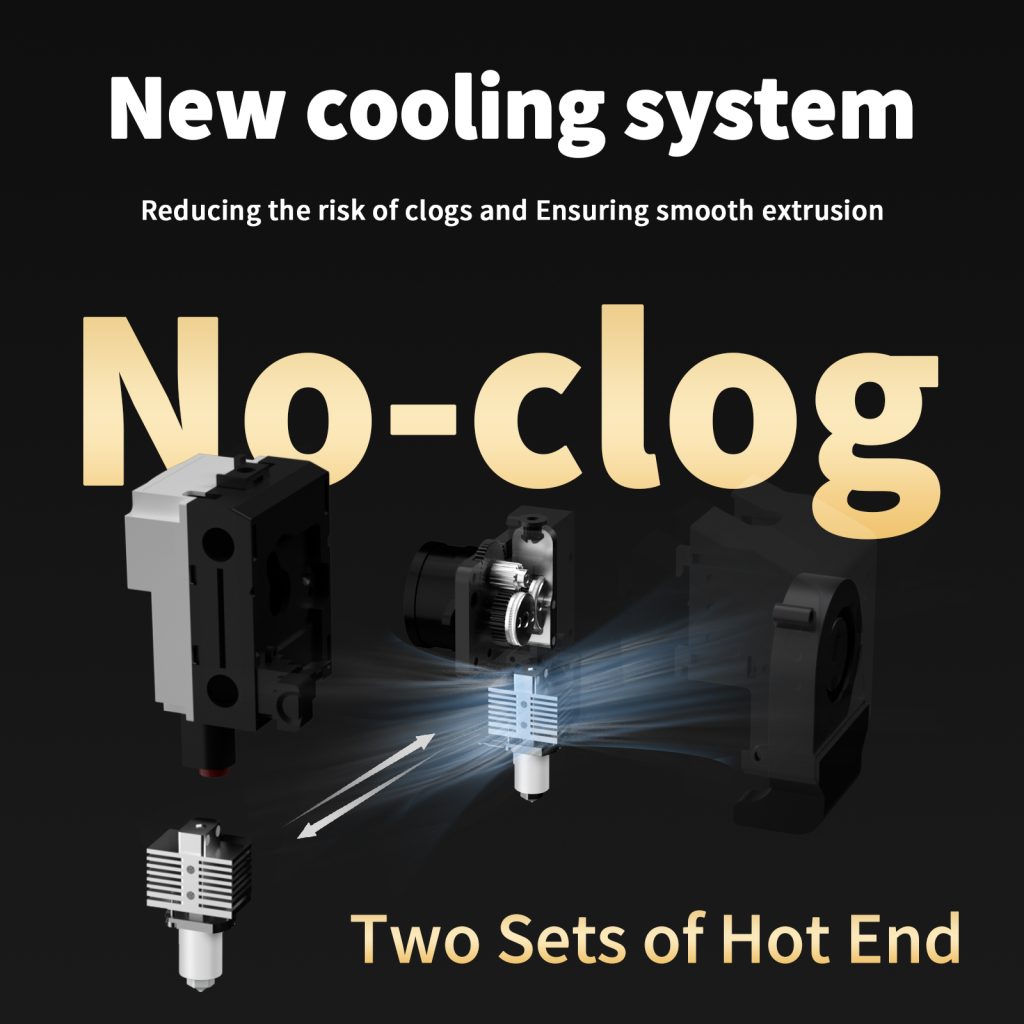

QIDI’s new cooling system and direct drive extruder also play a vital role in guaranteeing ultra-fast 3D printing speeds. The cooling system reduces clogging and ensures smooth extrusion. Moreover, the high-velocity hardened steel gear with a ratio of a 9.5:1 can achieve a strong and stable flow of 35mm3/s for high-speed 3D printing.

QIDI Tech’s open source Klipper firmware and QIDIslicer software allow for easy and efficient remote control 3D printing. Additional custom functions, such as camera monitoring, can also be achieved through QIDI Tech’s software. Users can learn more about camera installation here. The Klipper firmware also includes the KAMP feature, which can quickly ensure a flawless first layer for every 3D print.

Large-format, temperature controlled 3D printing

The new QIDI X-PLUS3 and X-MAX3 models are also notable for their build volumes. The X-PLUS3 boasts a large build volume of 280mm*280mm*270mm, whilst the X-MAX3 comes in at an impressive 325mm*325mm*315mm. In fact, the X-MAX3 is said to possess the largest closed-format 3D print size currently on the market. Both 3D printers can comfortably meet the 3D printing needs of users looking to produce large-scale objects, expanding the possible 3D printing applications.

Designed with rounded ceramic, the QIDI extruder nozzle heats up from 20°C to 220°C in just 30 seconds, reaching a maximum temperature of 350°C. Two new hotends are available for both the X-PLUS3 and X-MAX3. The new copper alloy nozzle offers superior thermal conductivity than ordinary brass, enabling durable and smooth 3D printing of ABS, PLA and PETG. QIDI’s hardened steel nozzle offers a longer life span, and can easily 3D print high-performance materials to a high standard.

Another notable feature of QIDI’s new X-PLUS3 and X-MAX3 3D printers is the new temperature controlled build chamber. Capable of heating up to a temperature of 65°C, this chamber prevents warping and cracking during the 3D printing process. What’s more, this precise temperature control system allows users to 3D print with a wide range of high-performance materials such as PET-CF and PAHT-CF. Equally, high 3D print quality is ensured when using high-performance, high-temperature materials such as ABS-GF and PETG.

The MAX3 also possesses a chamber circulation fan with an activated carbon air filter. This filters out any potential fumes or particles produced during the printing process, providing a cleaner and safer printing environment for the user

When 3D printing with ABS, PLA, and PETG, QIDI recommends users employ the copper alloy nozzle, as this will ensure the highest 3D printing quality. Both 3D printers offer a 20% improvement in 3D print accuracy over the previous generation MAX2 model.

These features make QIDI’s new 3D printers highly competitive within the FDM 3D printer market. For instance, both PLUS3 and MAX3 models offer superior printing size and print speeds than the competing X1 Carbon 3D printer by Bambu Lab. Moreover, with the X1 Carbon costing $1790.76, both of QIDI’s new 3D printers are significantly more affordable.

Customers can purchase QIDI Tech’s new X-PLUS3 3D printer here, while the X-MAX3 can be purchased for a special discounted price here.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.